Cleaning equipment and dust collector

A technology for cleaning equipment and dust bins, applied in cleaning equipment, vacuum cleaners, suction filters, etc., can solve the problems of easy dirty hands of users, low cleanliness in the cleaning process, manual cleaning, etc., to save time and improve cleaning methods Convenience and efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

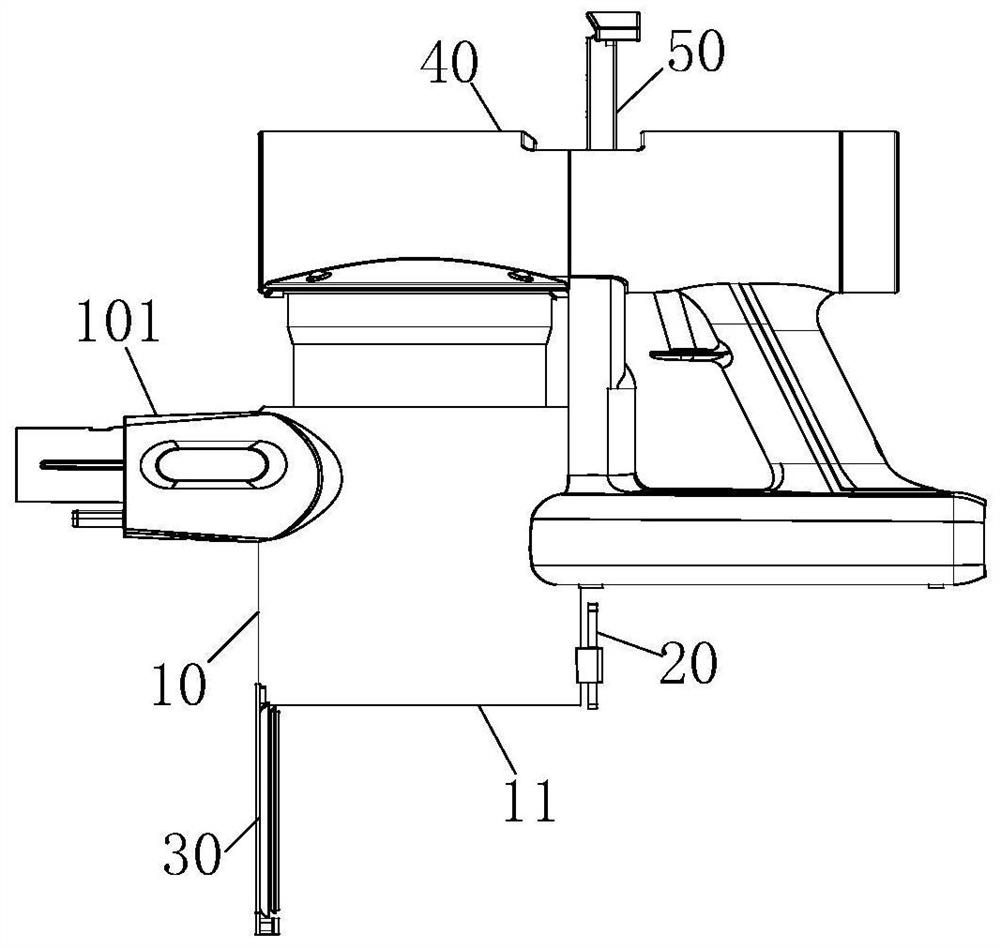

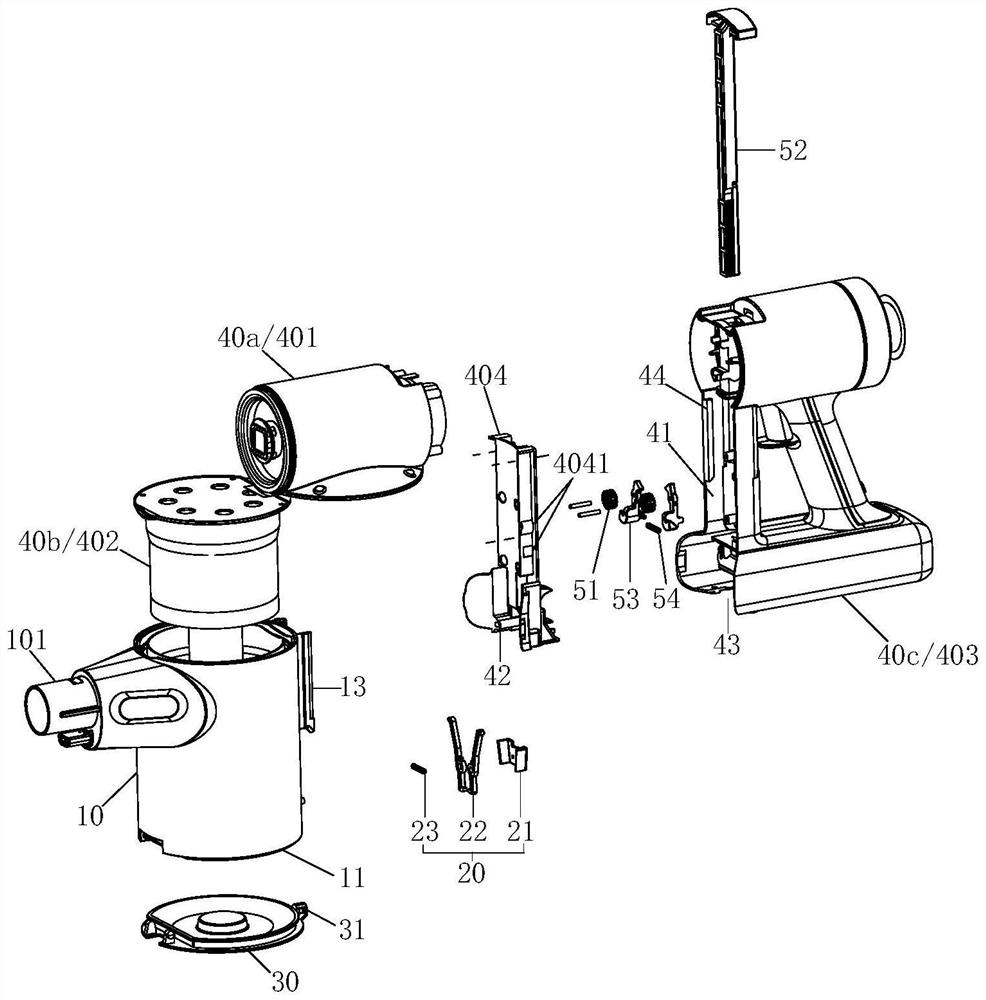

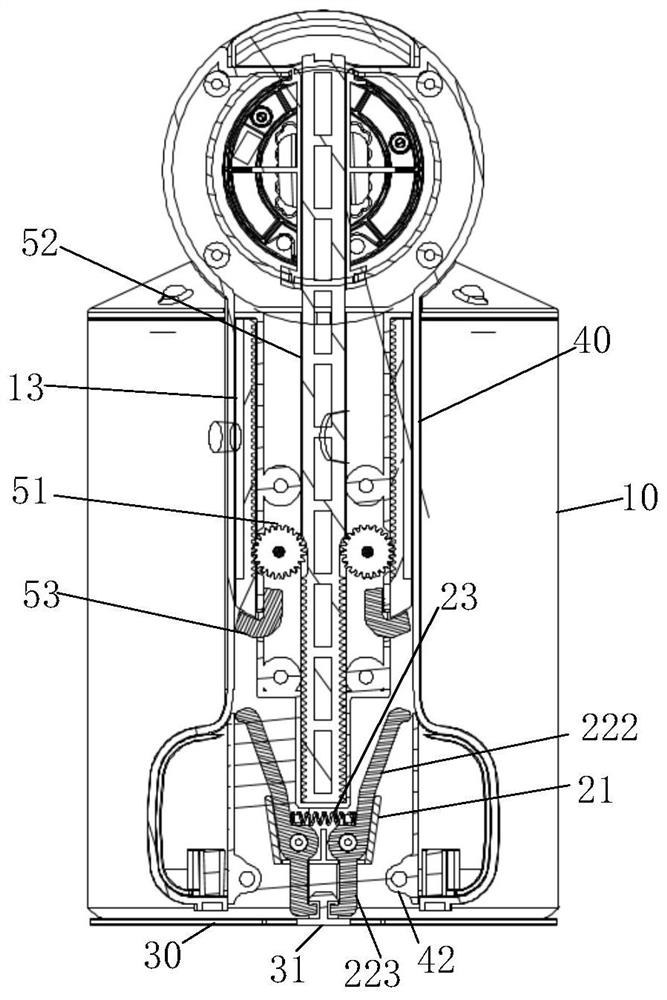

[0064] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0065] When the inventor practiced the embodiment of the present invention, he found that among the currently used vacuum cleaners, the dust collection devices used on the vacuum cleaners have certain defects when cleaning. For example, when users clean the dust bucket, they often get dirty. The user's hands, and the cleaning process is very cumbersome and time-consuming.

[0066] Tracing it to its cause, the inventor finds that the above-mentioned problems are caused by the connection structure of the dust bucket on the existing vacuum cleaner. When cleaning the dust bucket, it is necessary to remove the dust bucket from the host, and then pour out the dust in the dust bucke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com