Mattress with adjustable hardness

An adjustable, soft and firm technology, applied in the field of mattresses, can solve the problem of inability to adjust the soft and firm, and achieve the effect of wide adjustment range and high adjustment precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

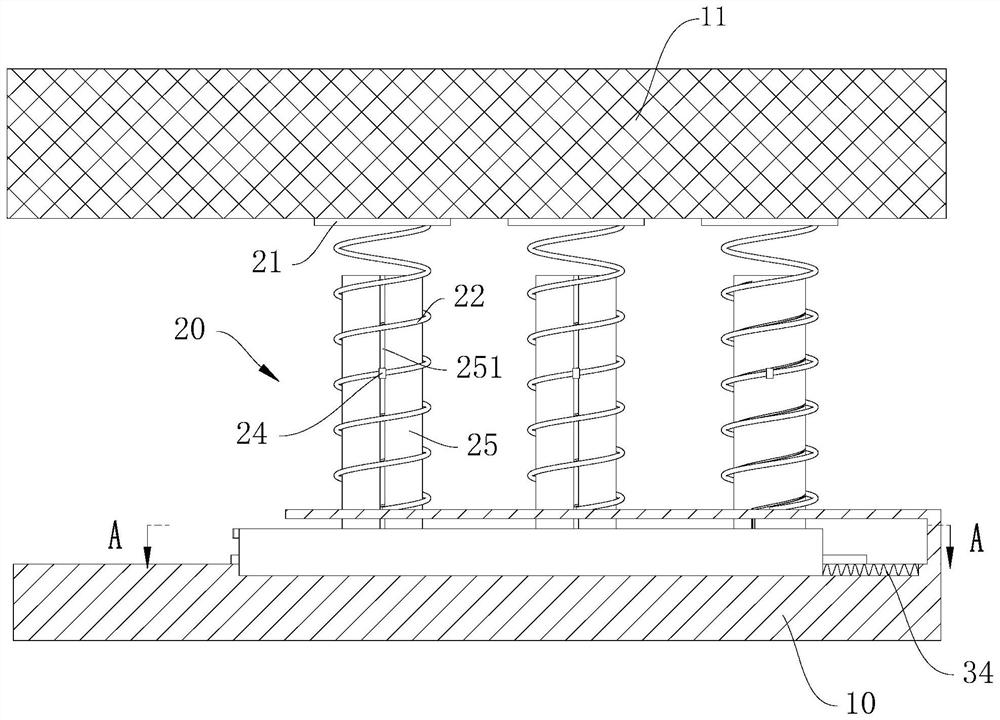

[0028] Such as Figure 1 to Figure 5 As shown, a mattress with adjustable hardness provided by the embodiment of the present invention includes a cushion 11 and a bottom plate 10, and the cushion 11 and the bottom plate 10 are a part of the bed structure in the prior art, and also includes:

[0029] Some adjustment springs 22, some adjustment springs 22 are arranged in rows, the same as the spring layout of spring mattresses in the prior art, arranged in rows and columns, the upper end of the adjustment springs 22 is connected to the lower side of the cushion 11, and the lower end is connected to the the upper end surface of the bottom plate 10; and,

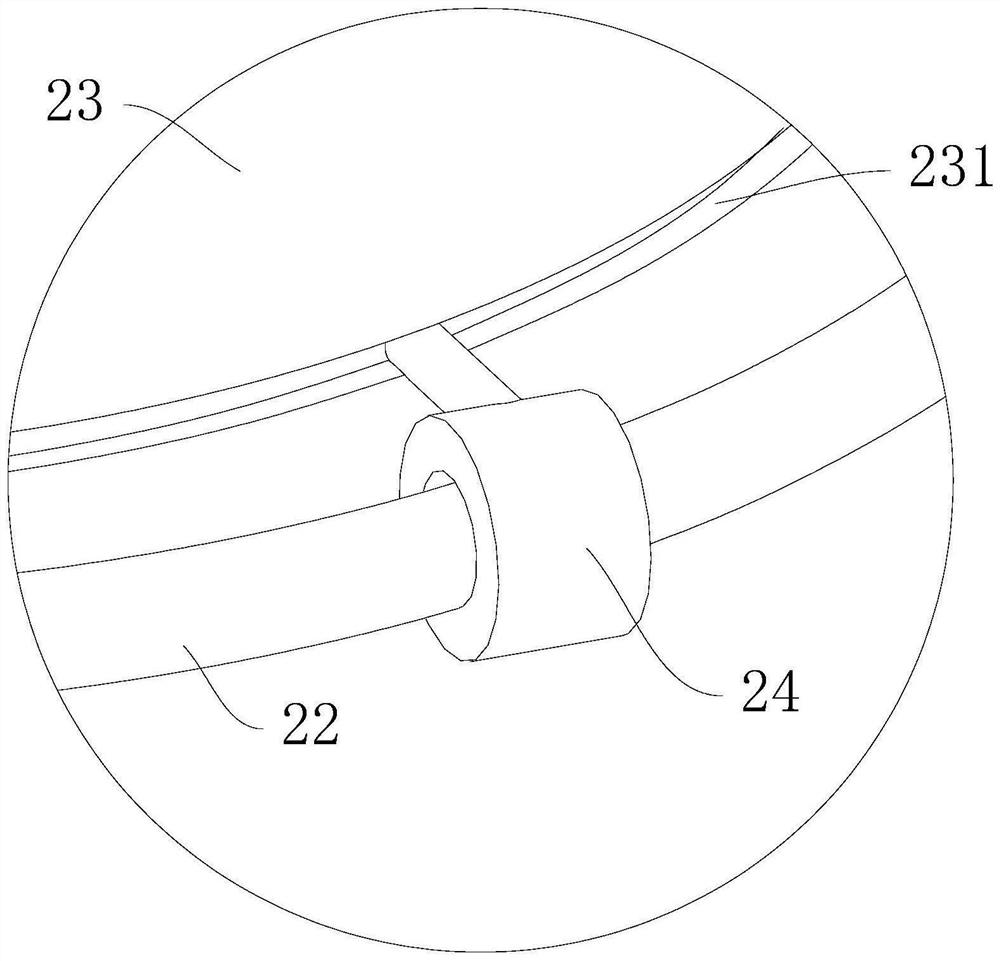

[0030] There are a plurality of adjusting devices 20 . The adjusting devices 20 correspond to the adjusting springs 22 one by one. The adjusting devices 20 are used to adjust the effective working length of the adjusting springs 22 so as to adjust the supporting force on the cushion 11 .

[0031] Specifically, it also includes ...

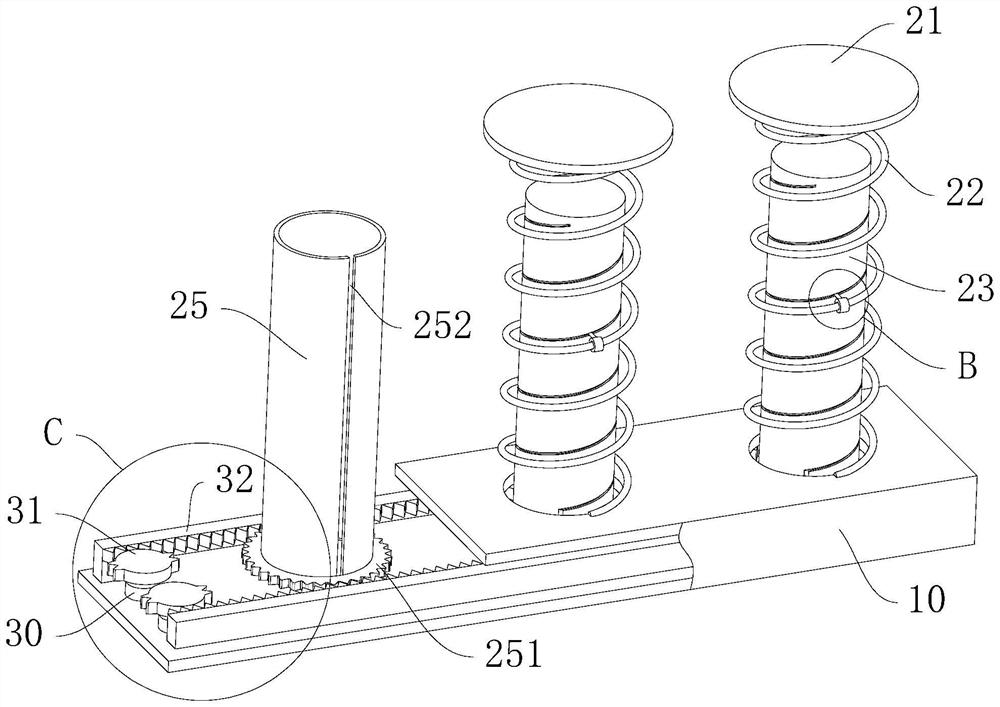

Embodiment 2

[0037] On the basis of Embodiment 1, the driving device includes a driving motor 30, a driving gear 31 and a driven rack 32, and the driven rack 32 is slidably arranged on the base plate 10, specifically, a chute can be provided on the base plate 10, The lower end of the driven rack 32 is provided with a driven slider matched with the chute, the lower end of the driving sleeve 25 is coaxially provided with a driving gear ring 251, and the driving motor 30 is fixedly arranged on the base plate 10, and the driving motor 30 is used to drive the driving gear. 31 rotates, the driving gear 31 meshes with the driven rack 32, the driving gear ring 251 meshes with the driven rack 32, and when the driving gear 31 drives the driven rack 32 to move, the driven gear 32 drives the driving gear ring 251 turn.

[0038] During installation, the driving motor 30 can be installed on one side of the mattress, and an external control panel can be connected to control the forward and reverse rotati...

Embodiment 3

[0040] On the basis of Embodiment 2, since the number of turns of the adjustment spring 22 is relatively large during actual installation, to achieve a wider range of adjustment, the length of the driven rack 32 needs to be longer, and when the length of the driven rack 32 When it is longer, a large space needs to be reserved on both sides of the mattress to give way to the movement of the driven rack 32, so that at least one side of the mattress lacks the adjustment spring 22 or the adjustment device 20, that is, at least one side Part of the adjustment spring 22 cannot be effectively adjusted.

[0041] In order to solve this problem, on the basis of Embodiment 2, in this embodiment, such as figure 1 with Figure 5 As shown, the drive device also includes a return spring 34, the driving gear 31 is an incomplete gear, one end of the return spring 34 is connected to the bottom plate 10, and the other end is connected to the driven rack 32; there are at least two drive devices, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com