Apparatus and method for reducing dust development in precision drill seeding

A precise and drill technology, applied in fertilizer and seeding equipment, sowing, application, etc., can solve problems such as treating the symptoms rather than the root causes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

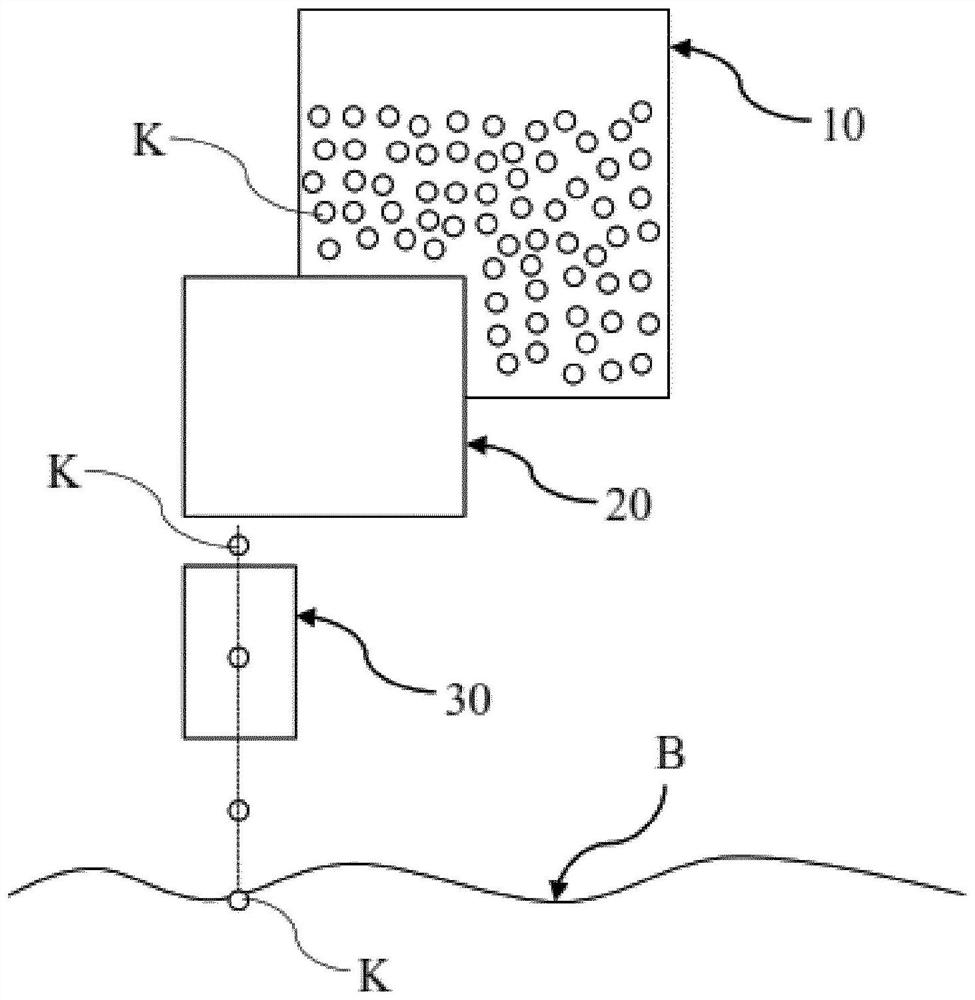

[0019] As used herein, the term "drill" is a device that sows crop seeds by positioning them in the soil and burying them to a specific depth. This ensures that the seeds will be evenly distributed. This drill plants seeds at the proper rate and depth to ensure the seeds are covered with soil. This keeps them from being eaten by birds and animals, or from drying out from exposure to sunlight. With drill machines, the seeds are distributed in rows, but the distance between the seeds along the row cannot be adjusted by the user, as for example in the case of vacuum precision planters. The distance between rows is typically set by the manufacturer. This setup allows the plants to get ample sunlight, nutrients and water from the soil.

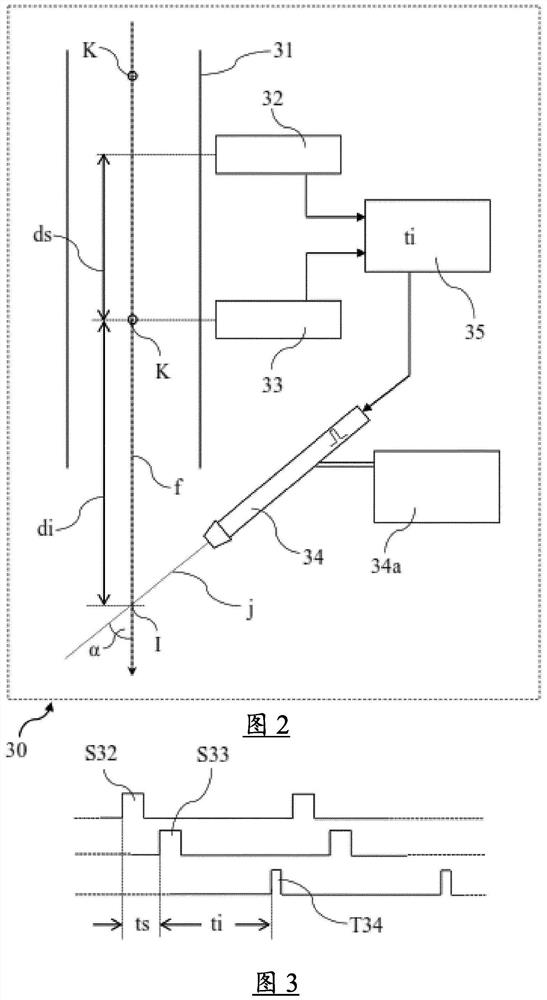

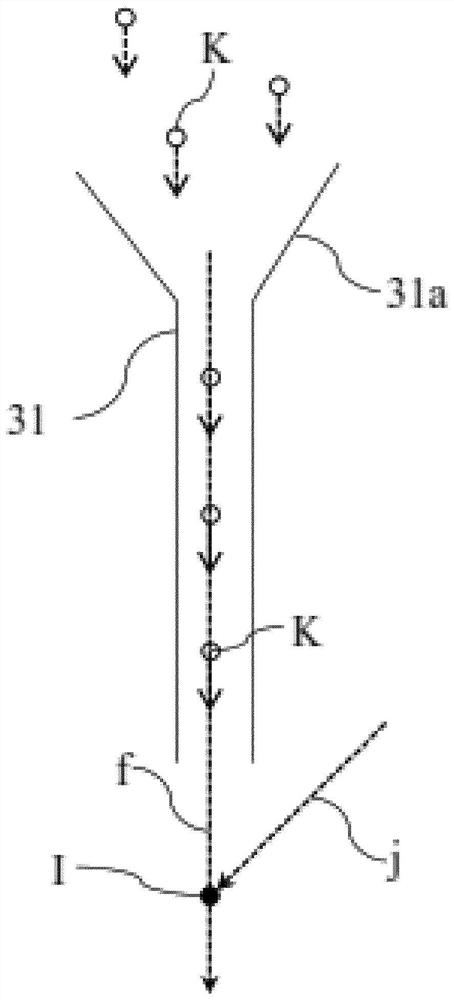

[0020] The seed dressing composition is selectively applied to the separated plant propagation material and the individual plant propagation materials to which the seed dressing has been applied are sequentially delivered onto the underlying sur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap