Hydraulic actuating mechanism for butt-welding processing of brazing aluminum alloy liquid cooling plate

An actuator and liquid-cooled plate technology, which is applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve problems such as difficult adjustment of the geometry of the flow channel on the board surface, and achieve convenient shaping and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

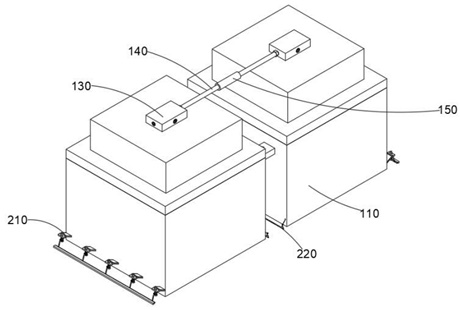

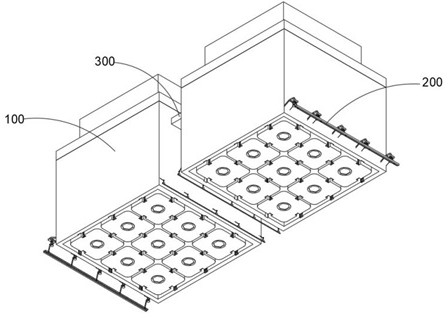

[0048] combine Figure 3-8 As shown, a hydraulic actuator for butt welding processing of brazed aluminum alloy liquid-cooled plates provided by the present invention includes a load-bearing connection mechanism 100, a liquid-cooled plate stabilization mechanism 200, a limit mechanism 300, a restraint mechanism 400 and a compression mechanism 500 , the liquid-cooled plate stabilization mechanism 200 is installed on the outside of the load connection mechanism 100, the limit mechanism 300 is installed on two adjacent load connection mechanisms 100, the restraint mechanism 400 is installed in the load connection mechanism 100, and the compression mechanism 500 is movable Connected in the load-bearing connection mechanism 100 .

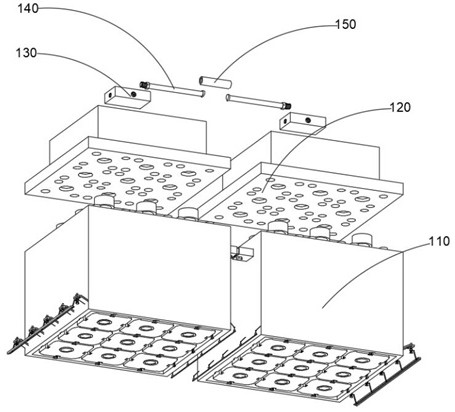

[0049] The load-bearing connection mechanism 100 includes a protective combination 110, a load-bearing plate 120, an adapter 130, a screw 140 and an empty tube 150, and the protective combination 110 also includes a safety shell 111 and an orientation rac...

Embodiment 2

[0052] combine image 3 As shown, on the basis of the first embodiment, by installing the transfer table 130 on the top of the load plate 120, and combining the screw 140 and the empty tube 150 to integrally splice multiple sets of protective combinations 110 and the load plate 120, so that the The device effectively adapts the pressurized shape of the liquid cooling plate, and at the same time sets a rack groove in the middle of the outer side of the pressure block 510 opposite to the directional rack 112, and under the action of the gear part 430, it can realize independent adjustment. The briquetting block 510 is stably lifted and retracted, and the load connection mechanism 100 also includes an adapter 130 installed at the center of the top of the load plate 120, a screw 140 connected in the adapter 130, and an empty tube 150 installed at the outer end of the screw 140, The protection combination 110 also includes a safety casing 111 and an orientation rack 112 installed i...

Embodiment 3

[0054] combine Figure 6 As shown, on the basis of the first embodiment, by installing the vertical rod 214 in the splint 215, combined with the lifting force exerted by the two springs on the top of the outer frame 213 on the pressure piece 211 as a whole, it can ensure that the liquid cooling plate is stable. Fix it, and insert a pad of the same material as the pad 212 into the slot at the bottom of the plug 222, so that the middle part of the liquid cooling plate can be effectively compressed. The corner booster assembly 210 also includes a Side splint 215, vertical bar 214 connected in the splint 215, outer frame 213 connected to the outside of the vertical bar 214, pressing piece 211 installed at the bottom of the outer frame 213, and pad 212 inserted in the groove at the bottom of the pressing piece 211 , the auxiliary stabilization combination 220 further includes a bracket 221 connected to the other side outside the safety housing 111 and an insert block 222 located in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com