Friction plate structure steering column locking device

A locking device and friction plate technology, applied in steering column, steering control, steering mechanism, etc., can solve the problems of small adjustment force and conflicting adjustment force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

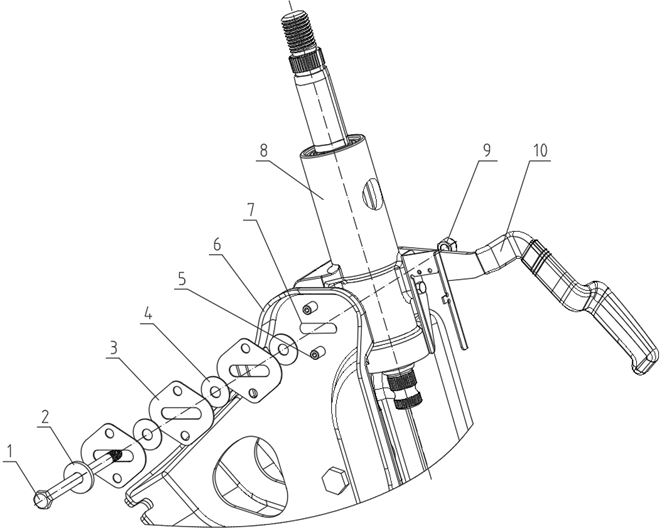

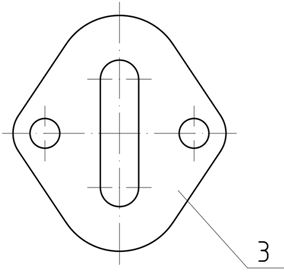

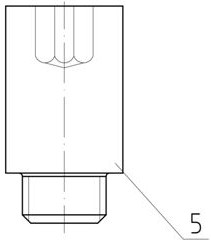

[0016] Such as Figure 1-3 As shown, the present invention includes an upper fastening bolt 1, a flat washer 2, a friction plate 3, a gasket 4, a fixing screw 5, a bracket welding composition 6, an arc-shaped notch 7, a pipe column 8, a self-locking nut 9, and a handle composition 10. It is characterized in that: a pipe column 8 is set in the middle of the two side plates of the support welding composition 6, the long notch provided on the pipe column 8 is aligned with the arc-shaped notch 7 of the support welding composition 6, and the two fixing screws 5 are threaded Connected and fixed on both sides of the arc-shaped notch 7 of the bracket welding composition 6, the two round holes of the friction plate 3 are fixed on the side of the bracket welding 6 through the cylindrical surface of the fixing screw 5, and three gaskets are arranged in the middle of the three friction plates 3 4. Use the upper fastening bolt 1 to pass through the flat washer 2, and then pass through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com