Source-load all-in-one machine device

An all-in-one, mode technology, applied in measurement devices, output power conversion devices, power supply testing, etc., can solve the problem that the electronic load CV, CC, CR, CP functions cannot be realized at the same time and cannot be further realized, and the bidirectional DC source cannot be realized. Electronic load function and other issues, to achieve the effect of easy use and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

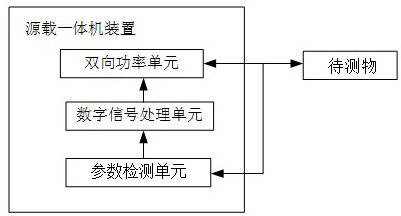

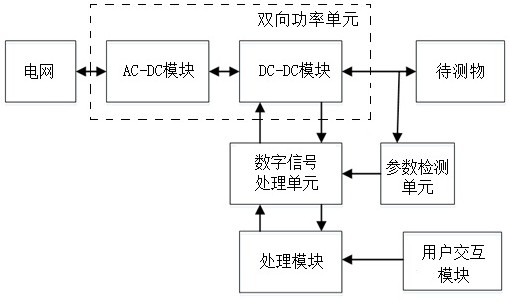

[0033] A source-load all-in-one device, which is used to perform a load test on an object to be tested or to charge and discharge the object to be tested, such as figure 1 , including a bidirectional power conversion unit, a parameter detection unit and a digital signal processing unit,

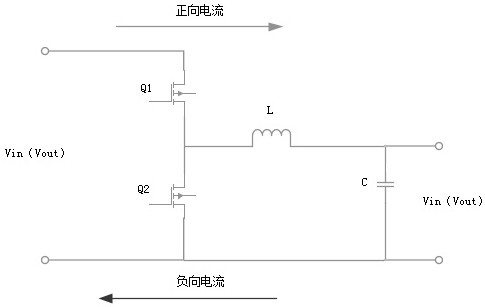

[0034] A two-way power conversion unit, which is respectively connected to the object under test and the power grid, has a two-way adjustable current mechanism, which is used to convert the AC voltage of the power grid into a DC voltage for the object under test or invert the DC voltage of the object under test into AC voltage to realize electric energy feedback to the grid;

[0035] A parameter detection unit, coupled between the bidirectional power conversion unit and the object under test, acquires and outputs detection parameters to the digital signal processing unit;

[0036] A digital signal processing unit, which controls the bidirectional power conversion unit, realizes the switching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com