Rapid blowdown device for pre-filter

A pre-filter, rapid sewage technology, applied in fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problems of reduced water flow, time-consuming, reduced filtration effect, etc., to improve the discharge speed, The effect of good sewage discharge and less residual impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

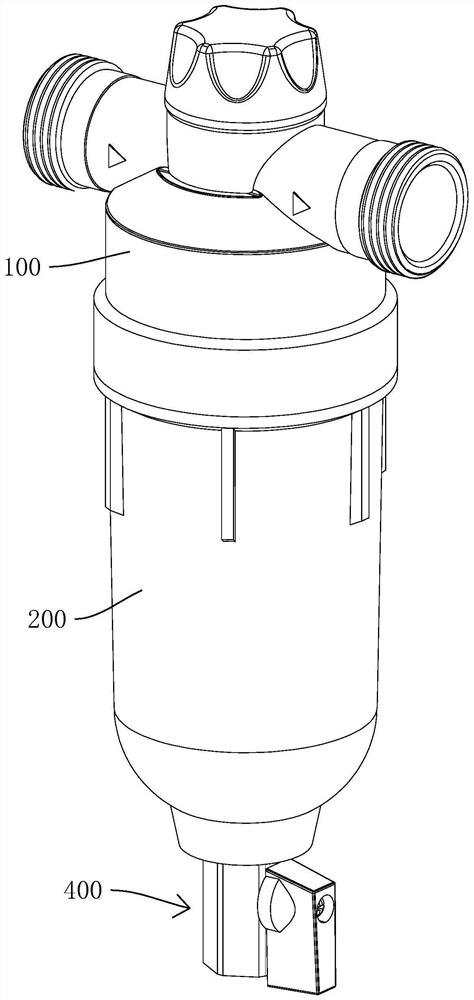

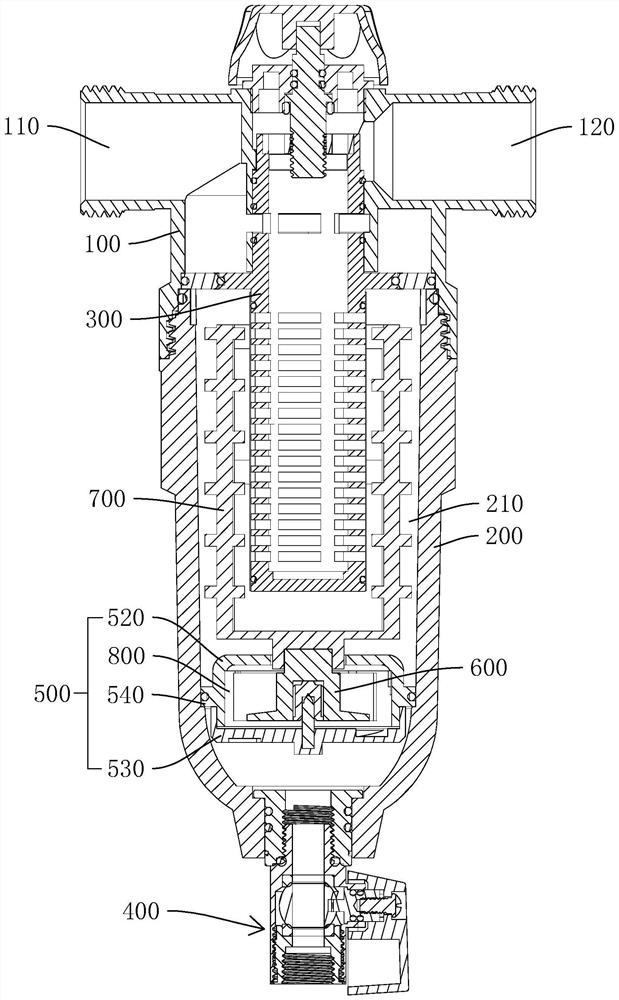

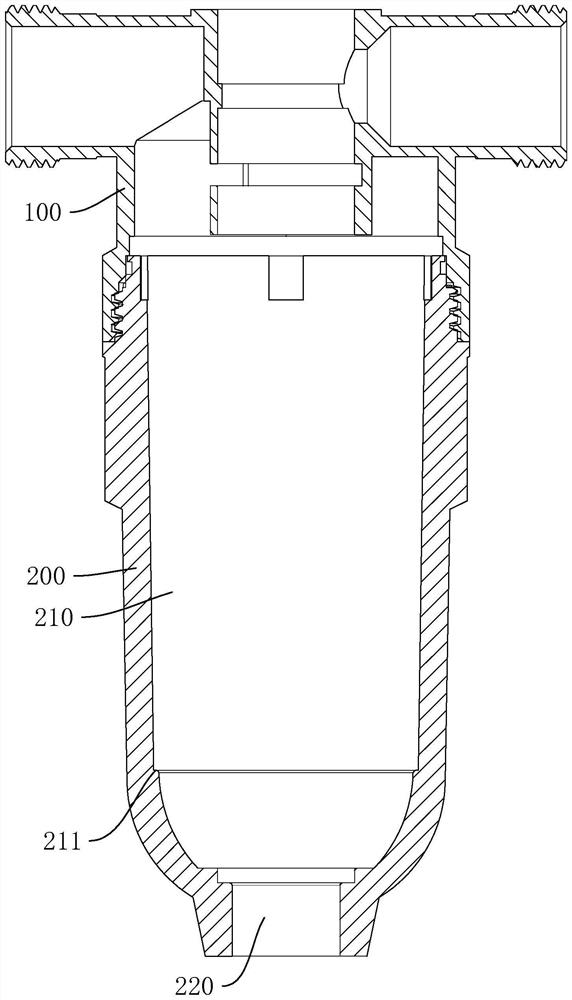

[0053] A kind of pre-filter fast sewage discharge device, such as Figure 1 to Figure 7 As shown, the pre-filter includes a body 100, a filter cup 200, a filter element 300 and a control device 400. The body 100 is provided with a water inlet channel 110 and an outlet water channel 120. The filter cup 200 is connected to the body 100. The filter cup 200 has Connected to the raw water chamber 210 of the water inlet channel 110, the filter element 300 is set in the raw water chamber 210 and communicated with the water outlet channel 120, the bottom of the filter cup 200 is provided with a drain hole 220, and the control device 400 can control the connection between the raw water chamber 210 and the outside world . The pre-filter can be a common filter in the prior art.

[0054] like figure 2As shown, the control device 400 is only used to control the connection between the raw water chamber 210 and the outside world, and the control device 400 may be an ordinary ball valve in...

Embodiment 2

[0068] The difference between embodiment two and embodiment one is: as Figure 8 to Figure 12 As shown, the control device 400 can also be a plug 410 connected to the drain hole 220 . The plug 410 is connected to the filter element 300 through the connecting rod 411 , and the connecting rod 411 runs through the second housing 530 , the impeller 600 , and the cleaning frame 700 . The plug 410 can move with the filter element 300 to seal or open the drain hole 220 .

[0069] In order to reduce the frictional force between the impeller 600 and the casing two 530 , a supporting member 900 is provided on the impeller 600 . The supporting member 900 may be a plane bearing 910 or a circular ring located between the impeller 600 and the second casing 530. As another solution, the supporting member 900 may also be a magnetic block 1 920 and a magnetic block 2 930, and the magnetic block 1 920 is arranged on On the impeller 600 , the second magnetic block 930 is disposed on the connect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap