Electric push rod suitable for deepwater environment

An electric push rod and environmental technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of push rod corrosion, thread structure loss, increase push rod force load, etc., and achieve the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

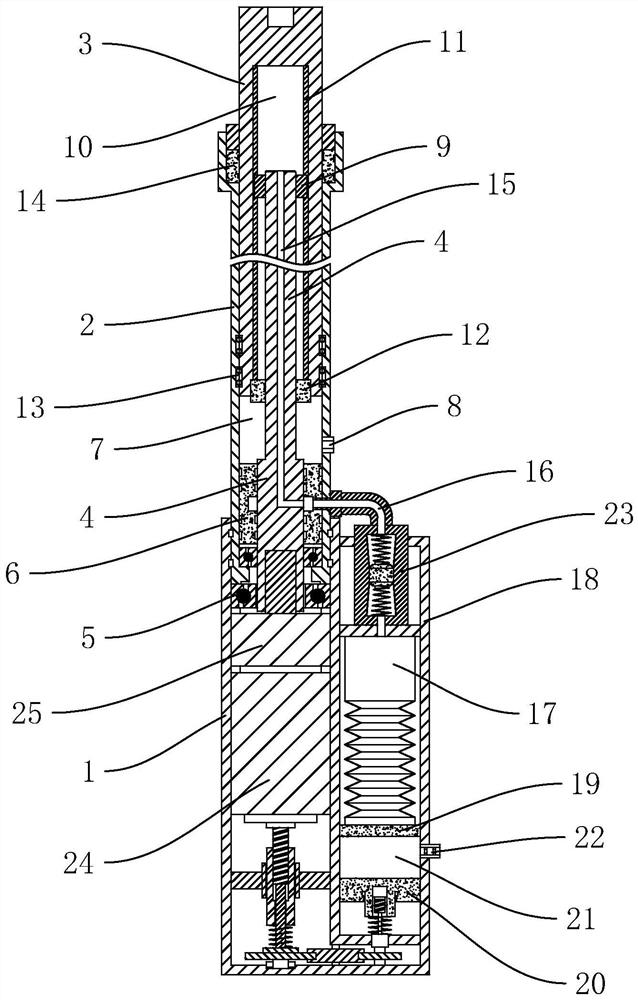

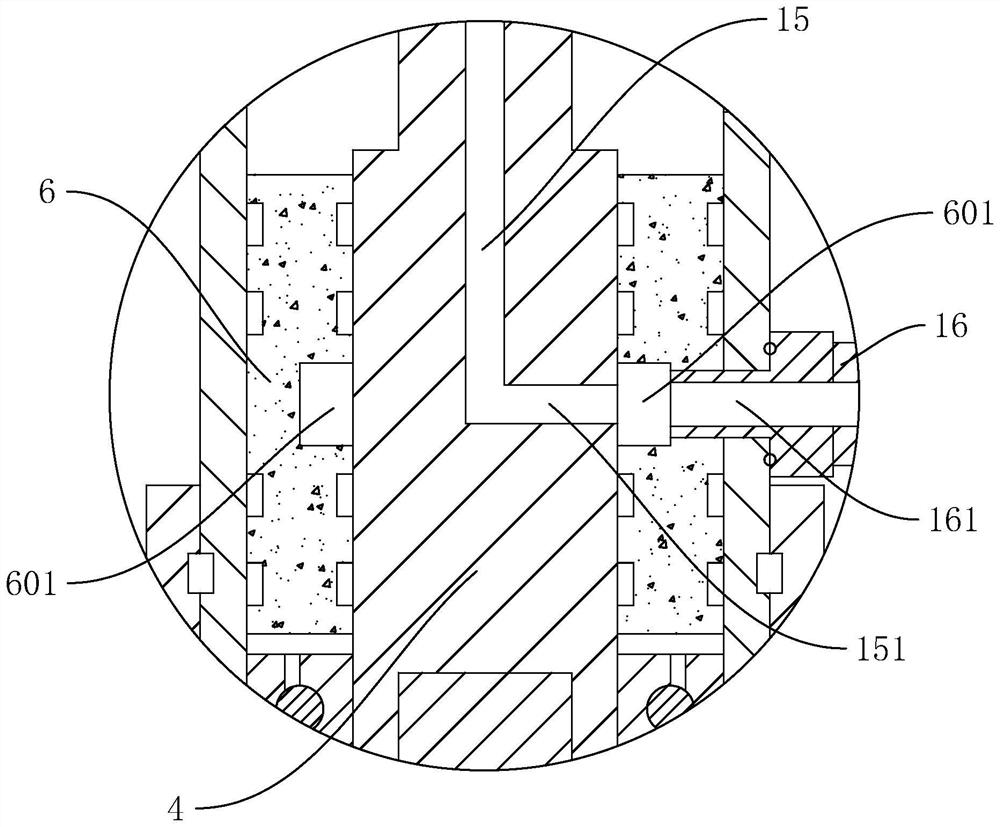

[0033] An electric actuator suitable for deep water environment, such as figure 1 As shown, it includes a driving device, an outer tube 2 and an inner tube 3, wherein the inner tube 3 is telescopically installed in the outer tube 2, and the end of the outer tube 2 is installed on the casing 1 of the driving device, and the screw thread is driven by the driving device The transmission structure can drive the inner tube 3 to move telescopically in the middle of the outer tube 2 .

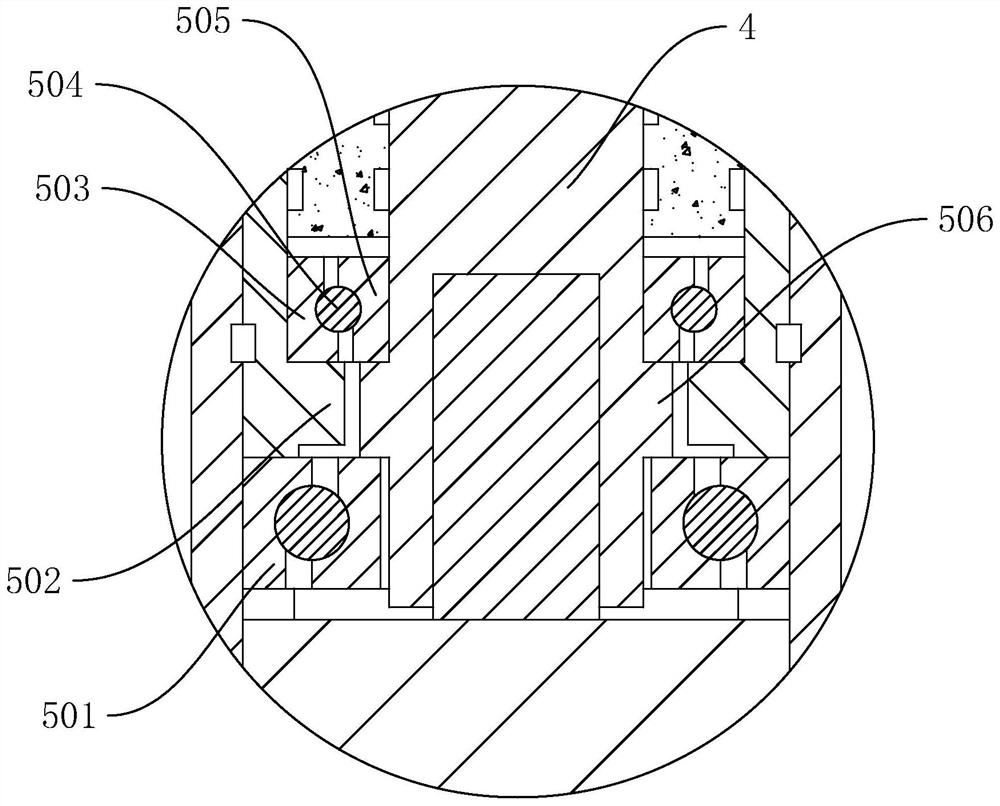

[0034] The driving device includes a motor 24, a reducer 25 and a rotating shaft 4, one end of the rotating shaft 4 is rotatably supported by a bearing assembly 5, and the other end of the rotating shaft 4 extends into the outer tube 2; the inner tube 3 is sleeved between the outer tube 2 and the rotating shaft 4 The inner pipe 3 is provided with a balance chamber 2 10, the end of the balance chamber 10 facing outward is closed, and the end facing the driving device is sealed with the outer periphery ...

Embodiment 2

[0037] An electric push rod suitable for deep water environment, which is further optimized on the basis of the first embodiment, the push rod also includes a pressure balance device, the pressure balance device includes an elastic oil storage bag 17, and the elastic oil storage bag 17 passes through the connecting pipe 16 communicates with the balance chamber 2 10 with the annular connection structure, and fills the elastic oil storage bag 17 and the balance chamber 10 with pressure-stabilizing oil, so that the balance chamber 2 10 can always be filled with the pressure-stabilizing oil, and the oil pressure is maintained with the external water pressure. A certain balance is stable, and it can also maintain constant lubrication performance through the stabilized oil of the threaded parts.

[0038] The elastic oil storage bag 17 of the pressure balance device can replenish and temporarily store the oil in the balance chamber 10, so as to adapt to the expansion and contraction c...

Embodiment 3

[0046] An electric push rod suitable for deep water environment, further optimized on the basis of the second embodiment, the elastic oil storage bag 17 communicates with the balance chamber 10 through the connecting pipe 16, and a buffer device 23 is connected to the connecting pipe 16 , the oil pressure between the elastic oil storage bag 17 and the balance chamber 10 can be buffered by the buffer device 23, that is, the elastic oil storage bag 17 can be connected to the balance chamber only when there is a certain pressure difference between the two. Chamber two 10 is connected.

[0047] refer to Figure 4 As shown, the buffer device 23 is provided with a buffer cavity 231, the buffer cavity 231 is cylindrical in the middle, and gradually expands towards the two ends, in the shape of a bell mouth. A buffer plug 232 is connected to the middle piston of the buffer chamber 231, and the two ends of the buffer plug 232 are elastically supported by a buffer spring 234, and both ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap