Inventory method for goods on goods shelf, robot and warehousing system

A technology of robots and robot bodies, applied to the inventory method of goods on shelves, in the field of robots and storage systems, to achieve the effects of convenient and correct retrieval, convenient goods, and convenient and timely error correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

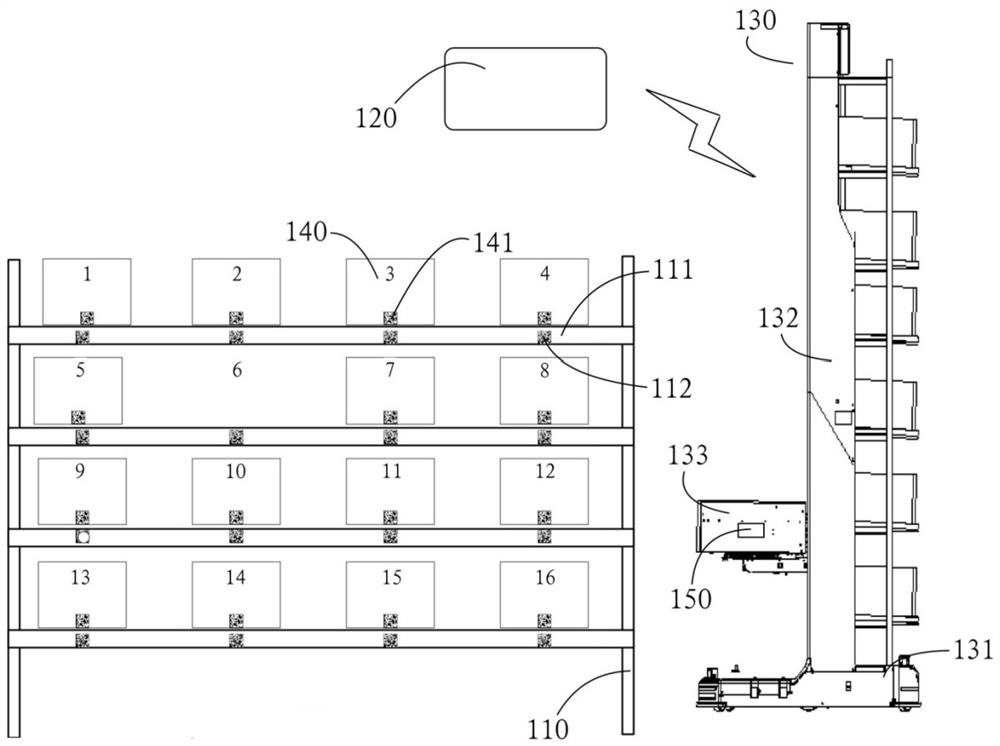

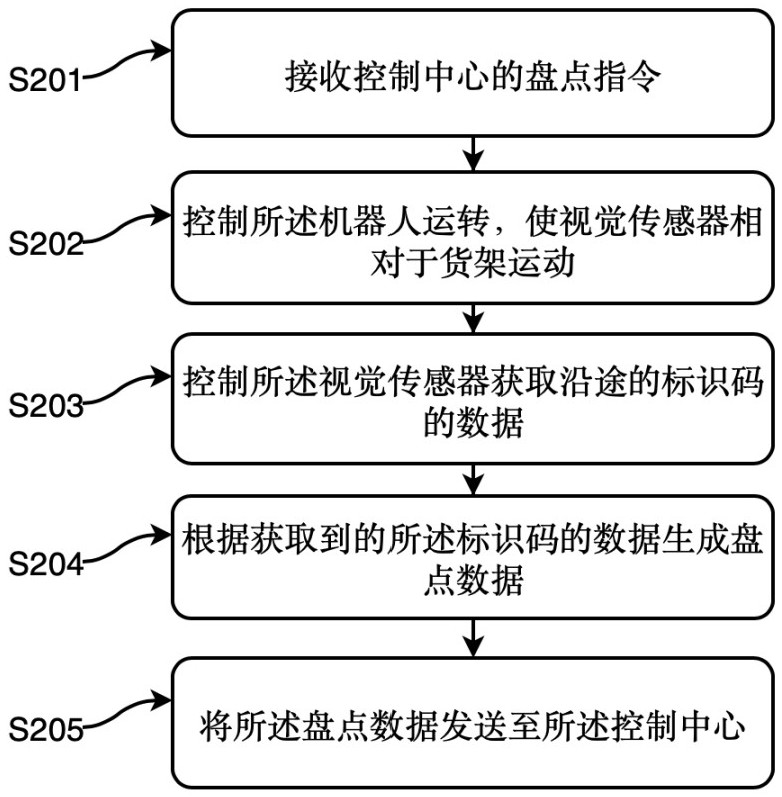

[0058] This embodiment provides a method for inventorying goods on shelves, which is applied to the robot 130 and implemented by the control unit of the robot 130. The method includes the following steps S201-S205 (the step numbers in the present invention are not used to limit the execution order, Steps can be executed sequentially, synchronously, interleaved, or reversed as needed):

[0059] Step S201, receiving an inventory instruction from the control center 120;

[0060] Step S202, controlling the operation of the robot 130 to make the visual sensor 150 move relative to the shelf 110;

[0061] Step S203, controlling the visual sensor 150 to acquire the data of the identification code along the way, wherein the identification code includes the shelf code 112 and the cargo code 141;

[0062] Step S204, generating inventory data according to the acquired data of the identification code; wherein, the inventory data includes the associated data of the shelf code 112 and the d...

Embodiment 2

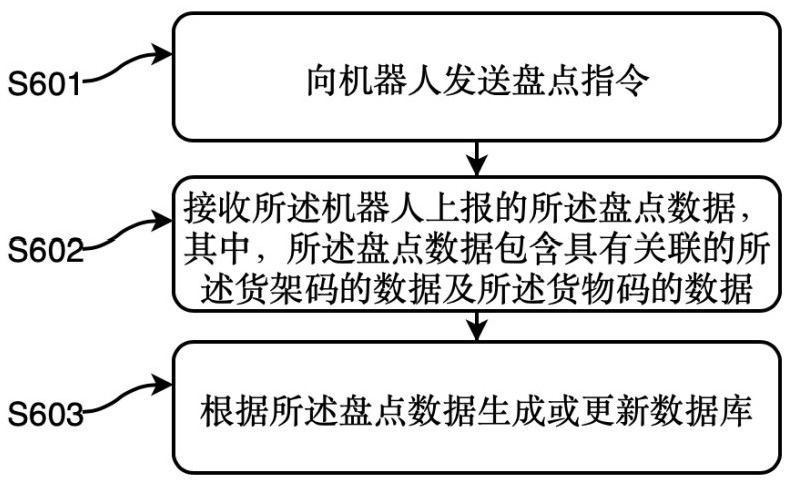

[0096] This embodiment provides a method for inventorying goods on shelves, which is applied to the control center 120, and the method includes the following steps S601-S603:

[0097] Step S601, sending an inventory instruction to the robot 130;

[0098] Step S602, receiving the inventory data reported by the robot 130, wherein the inventory data includes the associated data of the shelf code 112 and the data of the cargo code 141;

[0099] In a preferred embodiment, the received data also includes spare data reported by the robot 130 .

[0100] Step S603, generating or updating a database according to the inventory data.

[0101] Preferably, after receiving the inventory data reported by the robot 130 in the above step S602, it further includes: judging whether the inventory data is special data, and if so, executing corresponding preset measures for the special data. Specifically, the following steps S701-S702 are included:

[0102] Step S701, judging whether the first fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com