A combined cable tray with fixed structure

A fixed structure and cable tray technology, which is applied in the direction of electrical components, sustainable packaging, packaging recycling, etc., can solve the problems of single width of cable tray, too long overall protective shell, cumbersome maintenance and replacement, etc., so as to avoid the cumbersome installation of bolts , increase the fixed effect, and avoid the effect of economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

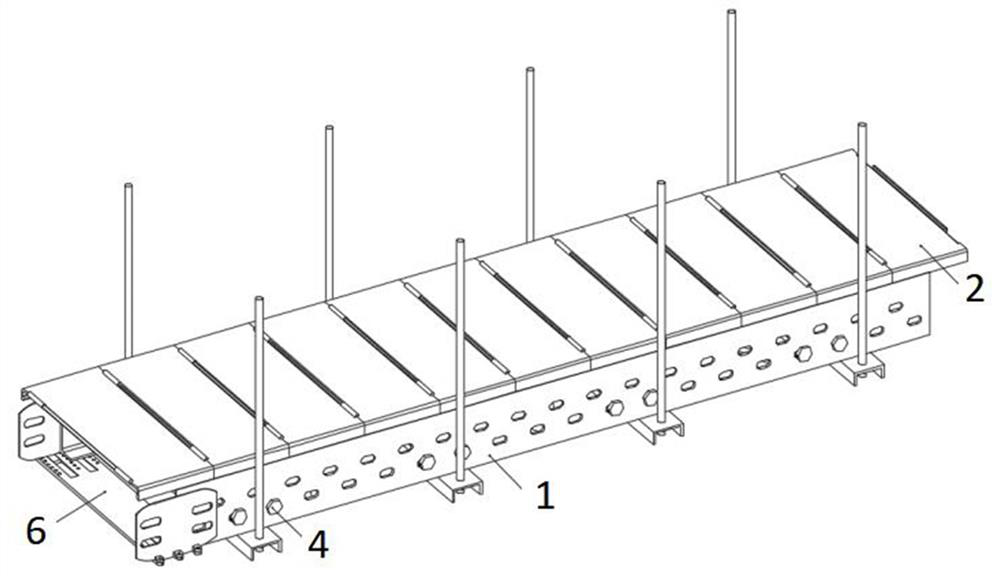

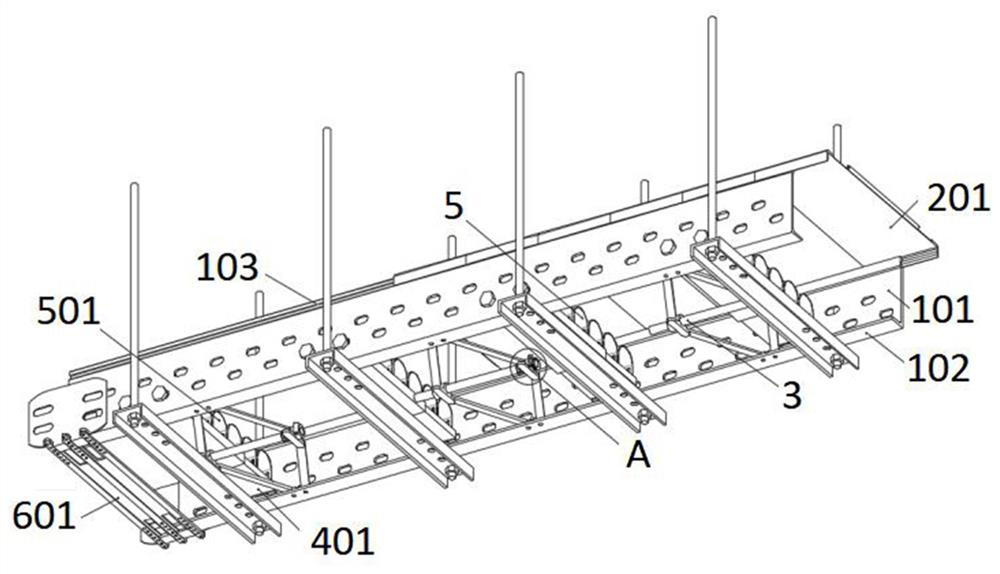

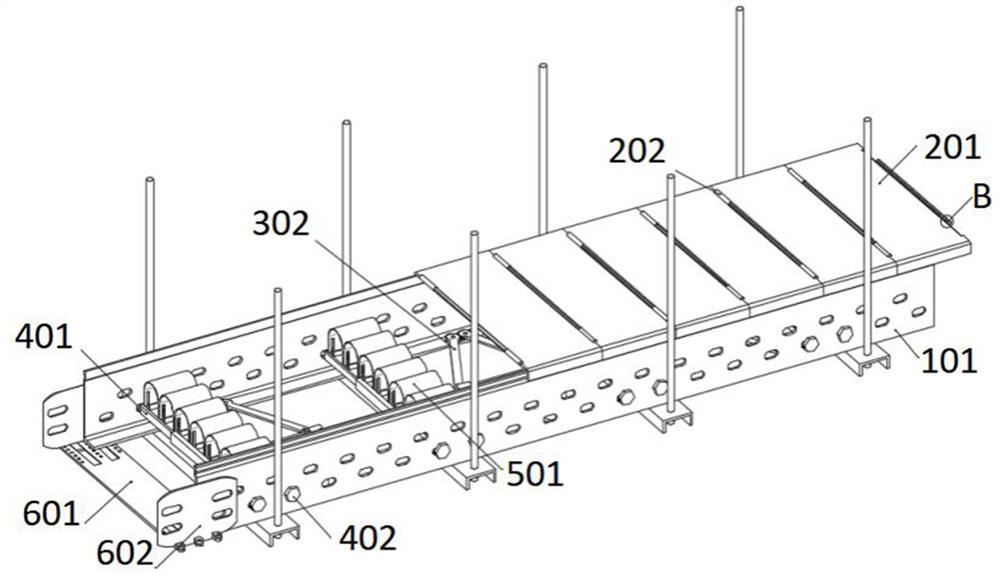

[0030] Example 1: as attached figure 1 to the attached Figure 12Shown: the present invention provides a combined cable tray with a fixed structure, including a groove structure 1; a protective structure 2, the protective structure 2 is a rectangular structure, and the protective structure 2 also includes: a protective plate 201, the protective plate 201 is Rectangular plate structure, the bottom of the front and rear sides of the protective plate 201 are provided with clips facing the lower end; the connecting shaft 202, the connecting shaft 202 is fixed at the left and right ends of the protective plate 201, the left connecting shaft 202 is an extension shaft structure, and the right connecting shaft 202 is a slotted shape, the groove body of the connecting shaft 202 is provided with a slot, and the connection shaft 202 fixed at the left and right positions of the protective plate 201 is used to realize the connection of each group of protective plates 201, and multiple grou...

Embodiment 2

[0033] Embodiment 2: Support structure 4, the support structure 4 adopts a telescopic mechanism, the support structure 4 is clamped and installed at the upper end position of the adjustment structure 3, the support structure 4 is clamped and installed with a fixed structure 5, and the end of the groove structure 1 is connected and installed with a connection Structure 6.

[0034] The support structure 4 further includes: a bearing plate 401, the bearing plate 401 is a rectangular long plate structure, the cross section of the bearing plate 401 is a U-shaped structure, and the bearing plate 401 adopts a telescopic structure; a reinforcing block 403, the reinforcing block 403 is a rectangular block structure , the reinforcement block 403 is fixed at the position of the end of the bearing plate 401, the reinforcement block 403 is in a vertical structure, the reinforcement block 403 is provided with three sets of mounting holes, and the bottom of the reinforcement block 403 is prov...

Embodiment 3

[0038] Embodiment 3: The connecting structure 6 can also be installed at a corner, and an extension plate with a waist hole is added to the outer connecting plate 602, so that the connecting plate 602 and the sliding plate 601 form a corner with an angle of fifteen degrees. board, so that the connecting structure 6 can be combined according to different needs, so that the connecting structure 6 can be adapted to the corners of the cables with different angles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com