A pipeline unevenness detection device for liquid swelling forming

A detection device and flatness technology, applied in the field of liquid expansion molding, can solve the problems of positioning pipelines, low detection accuracy, easy to produce errors, etc., and achieve the effects of cost saving, high degree of automation, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

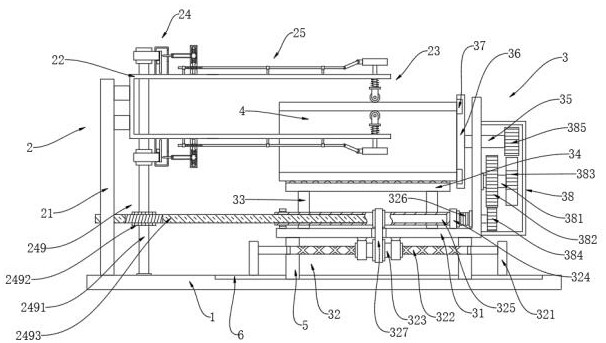

[0030] see Figure 1-5 , a pipeline unevenness detection device for liquid swelling, comprising a base 1, the upper end of the base 1 is fixedly connected with a detection mechanism 2 and a mobile support mechanism 3, and a steel pipe 4 is clamped on the mobile support mechanism 3;

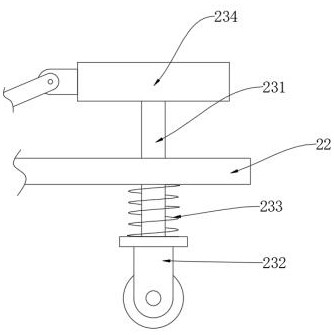

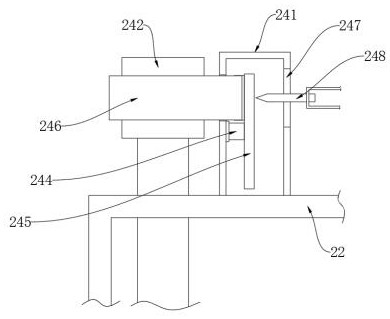

[0031]The detection mechanism 2 includes a bracket 21 that is fixedly connected to the upper end of the base 1 , and a U-shaped fixing rod 22 is fixedly connected to the upper end side wall of the bracket 21 . 22 One end close to the bracket 21 is fixedly connected with a graphic conversion mechanism 24 on the upper and lower sides, and the detection and collection end 23 and the graphic conversion mechanism 24 are connected by a displacement transmission mechanism 25;

[0032] The moving support mechanism 3 includes an L-shaped support plate 31 , the lower side of the L-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com