Three-dimensional parallel friction stir welding spindle device

A technology of friction stir welding and spindle device, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problem of insufficient structural rigidity, bearing capacity and service life, and it is difficult to meet the needs of thick plate welding and spatial three-dimensional curve welding for a long time. and other problems, to achieve the effect of sufficient structural rigidity and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

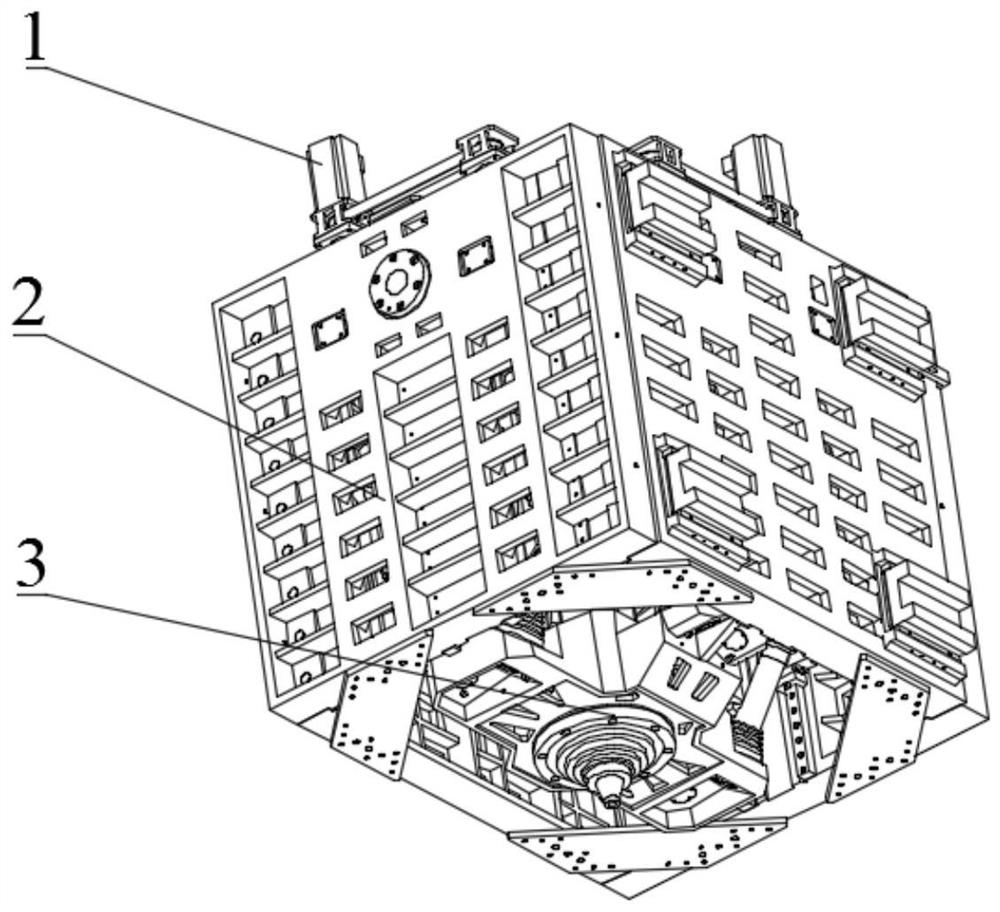

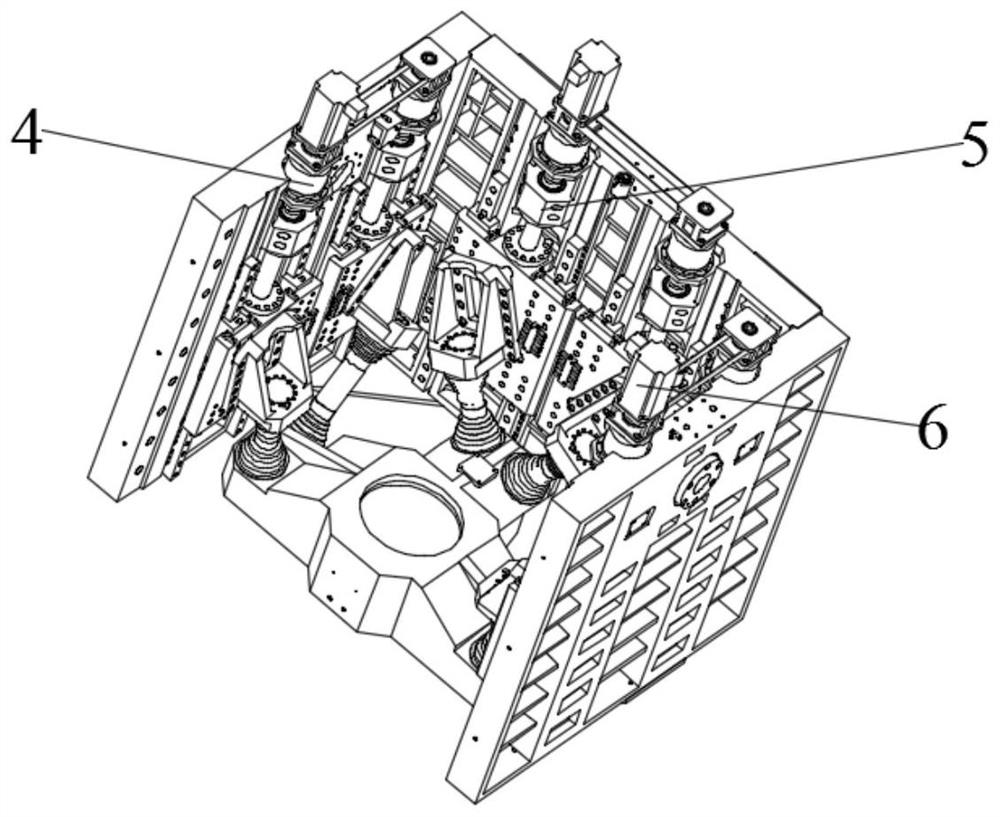

[0024] Such as Figure 1 to Figure 5 A three-dimensional parallel friction stir welding spindle device shown includes a frame 2; the frame 2 is cylindrical, and a host head 3 is fixed on the inner bottom thereof, and multiple groups of parallel mechanisms 1 are installed on the host head 3, each group There are a plurality of lead screw mechanisms in the parallel mechanism 1, and the lead screw mechanisms in multiple sets of parallel mechanisms 1 are installed in parallel.

Embodiment 2

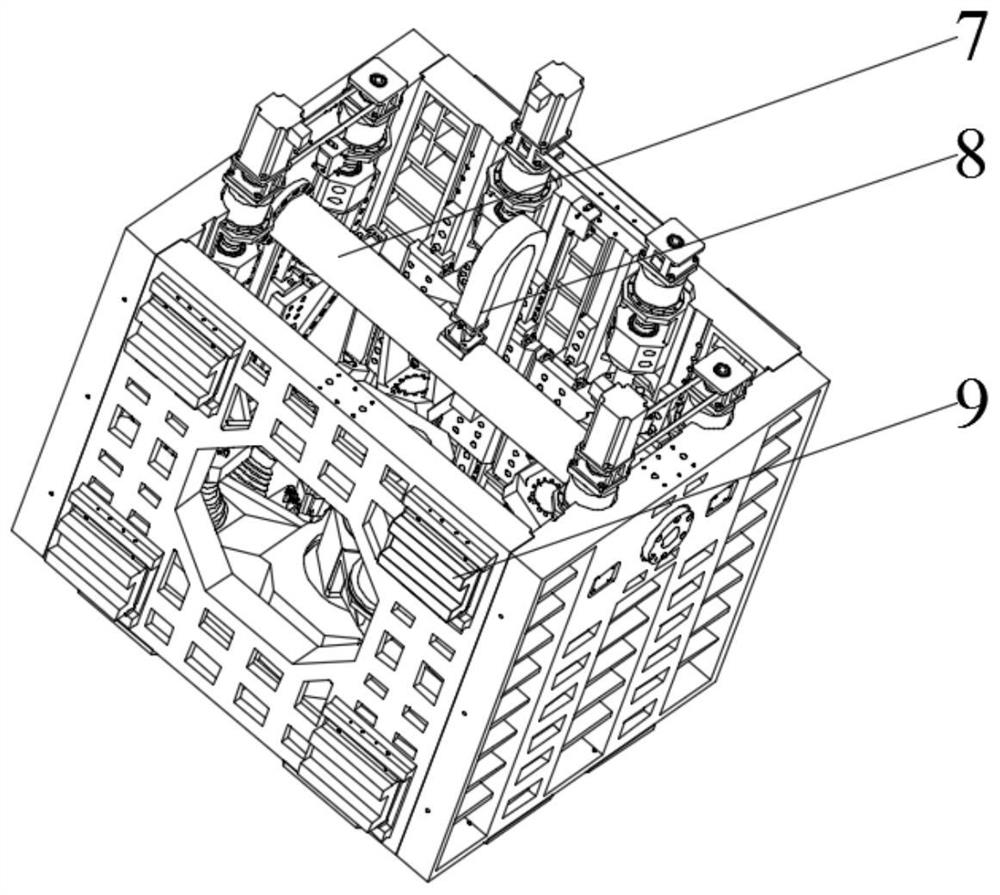

[0026] Based on Embodiment 1, the frame 2 is square tube-shaped, and there are three groups of parallel mechanisms 1 that are installed close to the three sides of the frame 2, and the side of the frame 2 that is not installed close to the parallel mechanism 1 is the fourth side.

Embodiment 3

[0028] Based on Embodiment 2, a slider 9 is installed on the outer wall of the fourth side of the frame 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com