Automatic pull rod screwing machine

A tie-rod and automatic technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low installation efficiency, achieve the effect of realizing detection, ensuring assembly accuracy, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

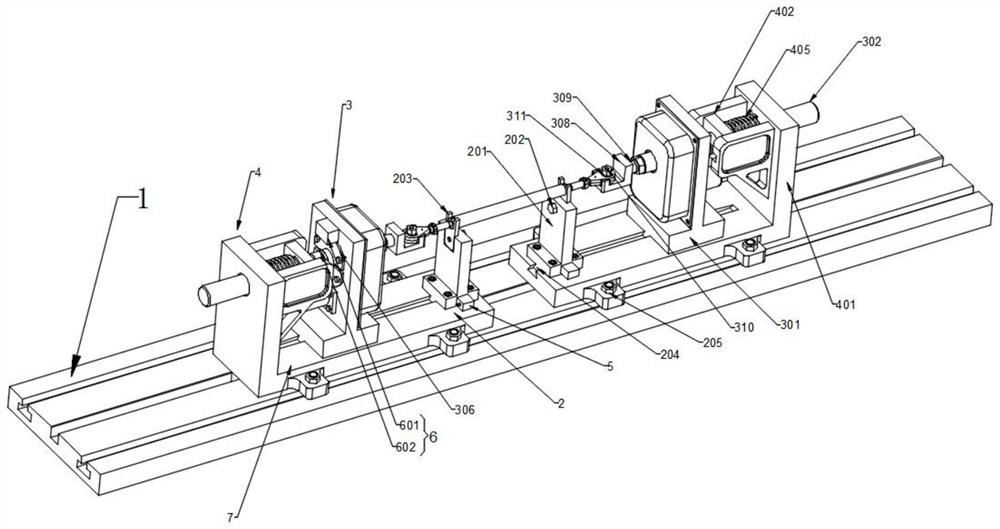

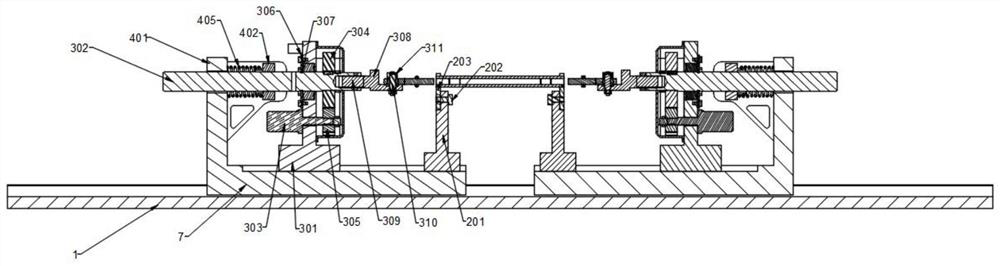

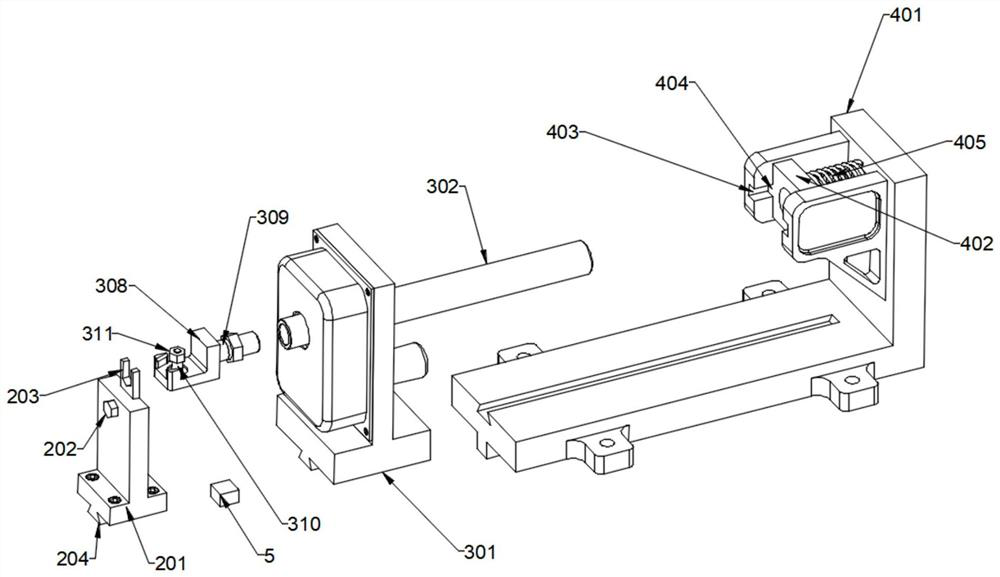

[0038] refer to Figure 1 to Figure 6 , the present application discloses an automatic tie rod screwing machine, including a workbench 1, on which several slide rails are arranged, the cross-section of the slide rails is dovetail-shaped or T-shaped, and the workbench 1 is provided with Two adjustment seats 7, the adjustment seats 7 are provided with slide bars adapted to the slide rails, and at the same time, locking screws 205 for fixing the adjustment seats 7 are also provided on both sides of the adjustment seats 7;

[0039]The screwing machine also includes a pull rod fixing device 2 and a sliding screwing device 3, wherein the pulling rod fixing device 2 includes two supporting seats 201 with the same structure, and the sliding screwing device 3 includes two sliding seats 301 with the same structure, The top surface of the adjustment seat 7 is provided with a chute 403, and the bottom surface of the support seat 201 and the bottom surface of the sliding seat 301 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com