Highway bridge pipeline supporting equipment

A technology for pipeline support and highway bridges. It is applied to pipeline supports, mechanical equipment, pipes/pipe joints/fittings, etc. It can solve the problems of inconvenient pipeline fixing, inconvenient adjustment of support height, complicated operation, etc., and achieve fast pipeline fixing and simple structure. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

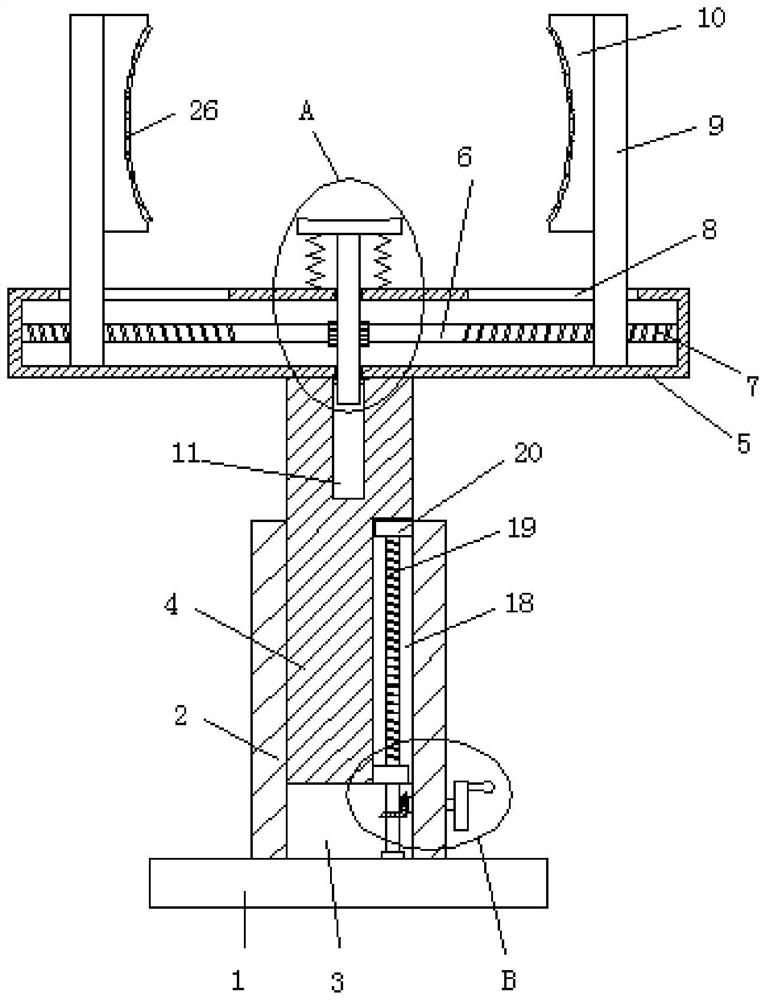

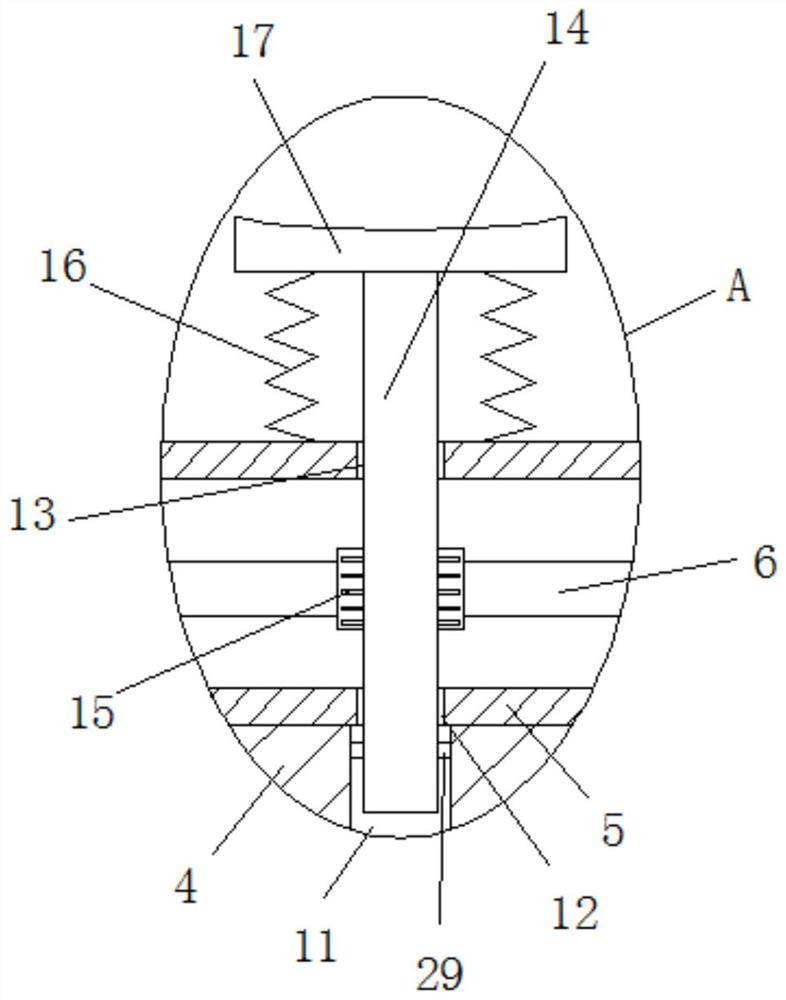

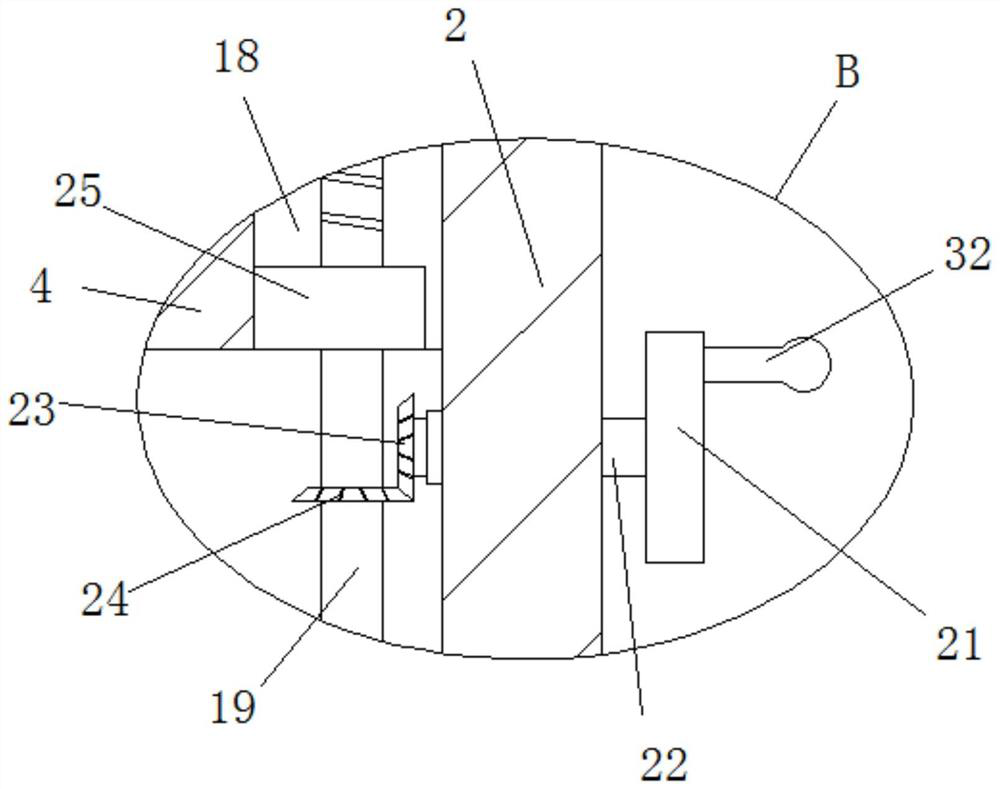

[0027] refer to Figure 1-5 , a highway bridge pipe support device, comprising a base 1, a rectangular column 2 is installed on the top of the base 1, a rectangular hole 3 is opened on the rectangular column 2, a rectangular rod 4 is slidingly installed in the rectangular hole 3, and the top of the rectangular rod 4 is installed There is a support box 5, and the top of the support box 5 is provided with two strip holes 8, and a fixed rod 9 is slidably installed in the two strip holes 8, and a fixing mechanism is installed on the inside of the two fixed rods 9, and the support box 5 A threaded mechanism is installed inside, and the two fixed rods 9 are connected with the threaded mechanism. A conflicting mechanism is installed on the support box 5, and the conflicting mechanism is connected with the threaded mechanism. A lifting mechanism is arranged in the rectangular hole 3, and the side of the rectangular rod 4 is provided with a Rectangular mouth 18, lifting block 25 is ins...

Embodiment 2

[0036] refer to Figure 1-5, a highway bridge pipe support device, comprising a base 1, a rectangular column 2 is installed on the top of the base 1, a rectangular hole 3 is opened on the rectangular column 2, a rectangular rod 4 is slidingly installed in the rectangular hole 3, and the top of the rectangular rod 4 is installed There is a support box 5, and the top of the support box 5 is provided with two strip holes 8, and a fixed rod 9 is slidably installed in the two strip holes 8, and a fixing mechanism is installed on the inside of the two fixed rods 9, and the support box 5 A threaded mechanism is installed inside, and the two fixed rods 9 are connected with the threaded mechanism. A conflicting mechanism is installed on the support box 5, and the conflicting mechanism is connected with the threaded mechanism. A lifting mechanism is arranged in the rectangular hole 3, and the side of the rectangular rod 4 is provided with a Rectangular mouth 18, lifting block 25 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com