System and method for safely compensating weight of robot

A safety compensation and robot technology, applied in the field of robots, can solve the problems of programming system and compilation system errors, difficulty in exerting safety functions, and affecting the safety of cooperative workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to achieve the above object, the present invention uses technical means and effects thereof, examples are given, and are described as follows in conjunction with the accompanying drawings.

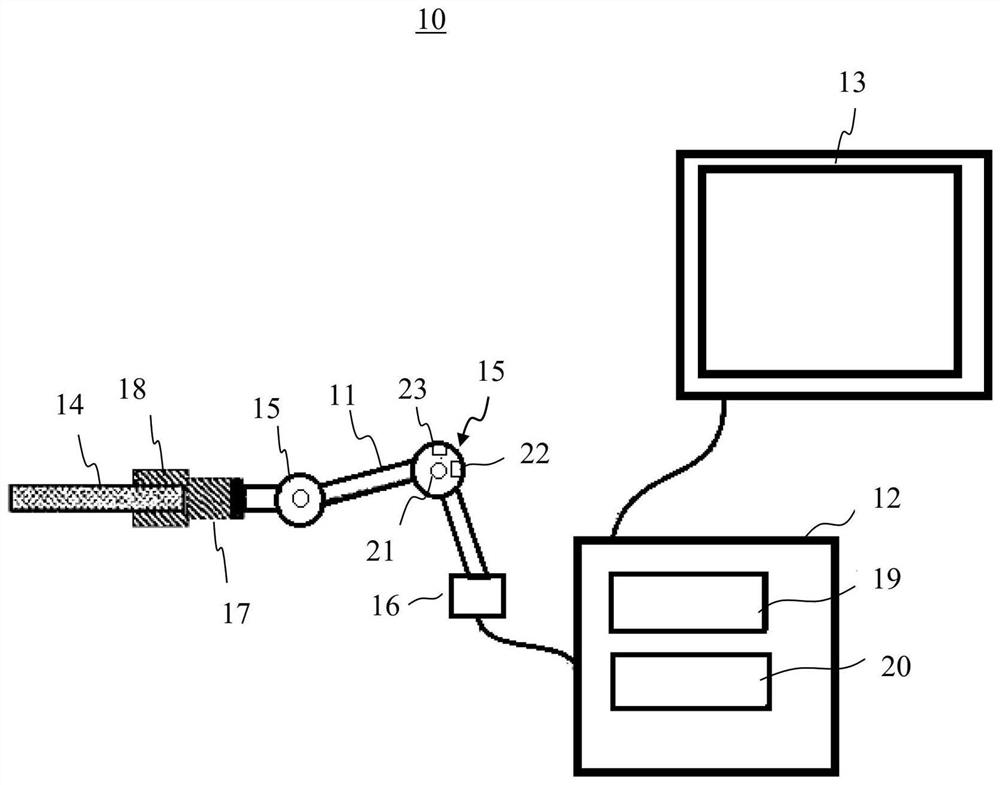

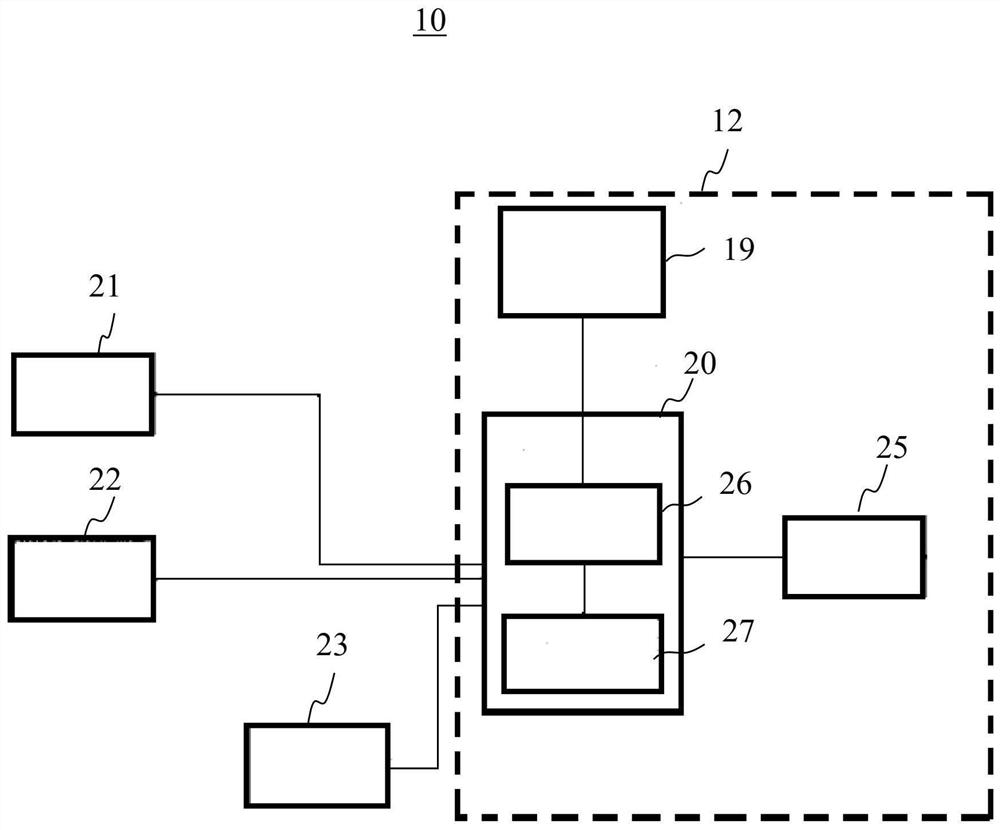

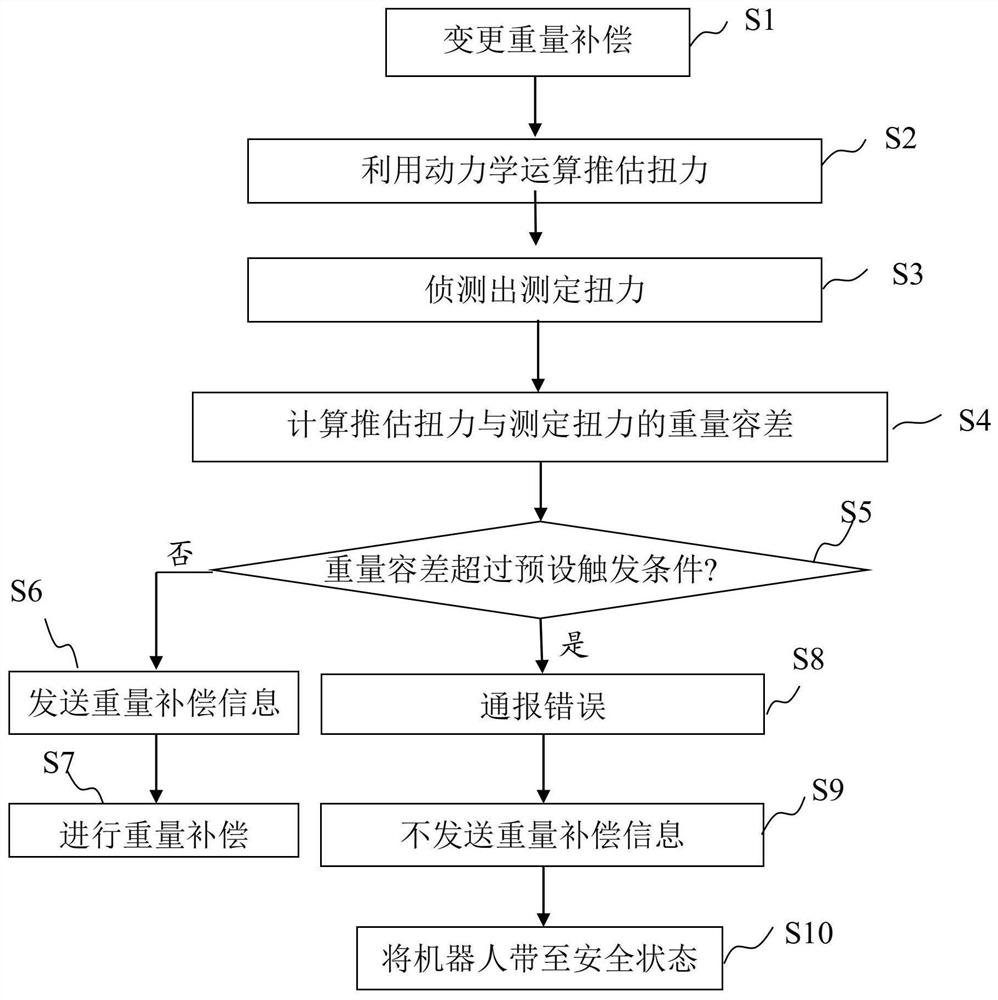

[0033] Please also see Figure 1 to Figure 2 , figure 1 It is a schematic diagram of the robot safety compensation weight system of the present invention, figure 2 It is a functional block diagram of the robot safety compensation weight system of the present invention. figure 1 Among them, the robot safety compensation weight system 10 of the present invention includes a robot 11, a controller 12, a man-machine interface 13, a workpiece 14, and the like. The robot 11 has a multi-joint 15, one end is a fixed base 16, and the other end is a movable end 17, and the end 17 is connected with a tool 18 such as a gripper. The robot 11 is connected to the controller 12 , and the controller 12 includes a control unit 19 and a safety module 20 . The controller 12 controls the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com