Platform for measuring radial rigidity of main shaft

A platform and rigid technology, applied in the field of the platform for measuring the radial rigidity of the main shaft, can solve the problems of manual handling, time-consuming and laborious, inconvenient to adapt to measuring personnel of different heights, etc., and achieve the effect of increasing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

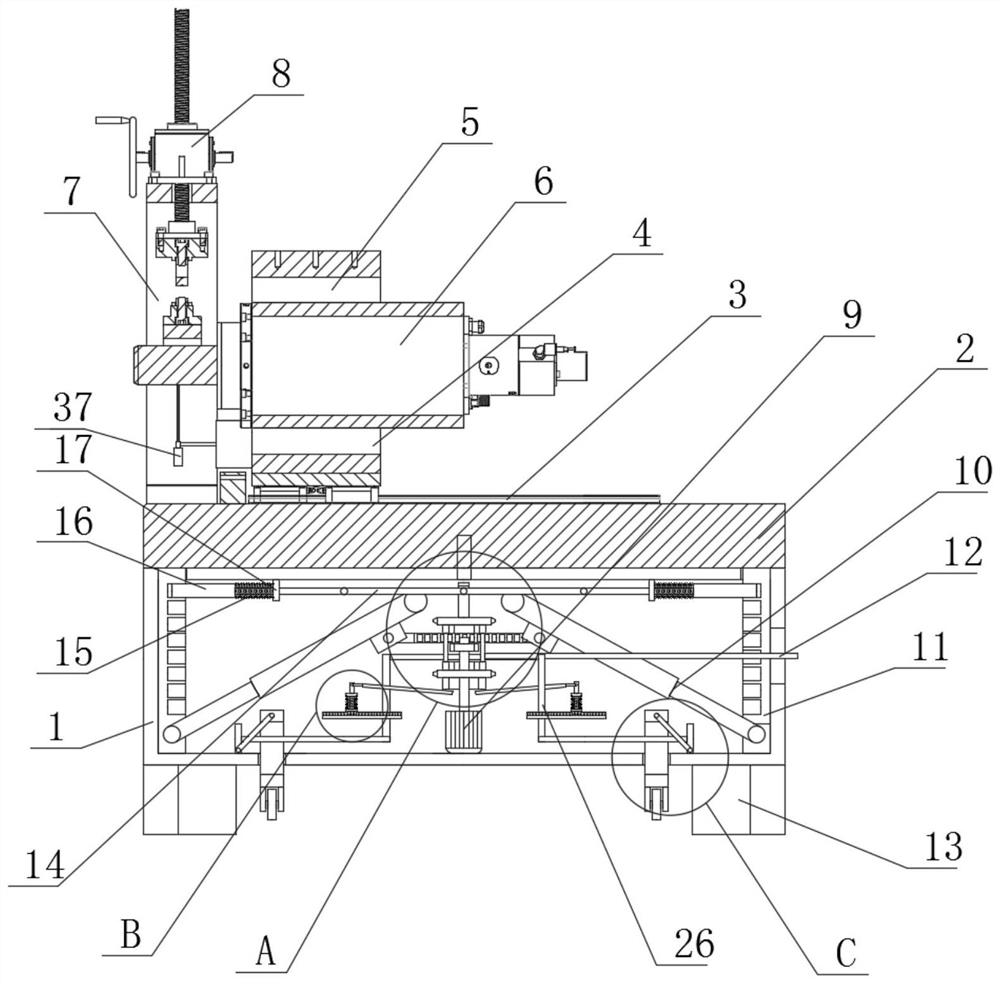

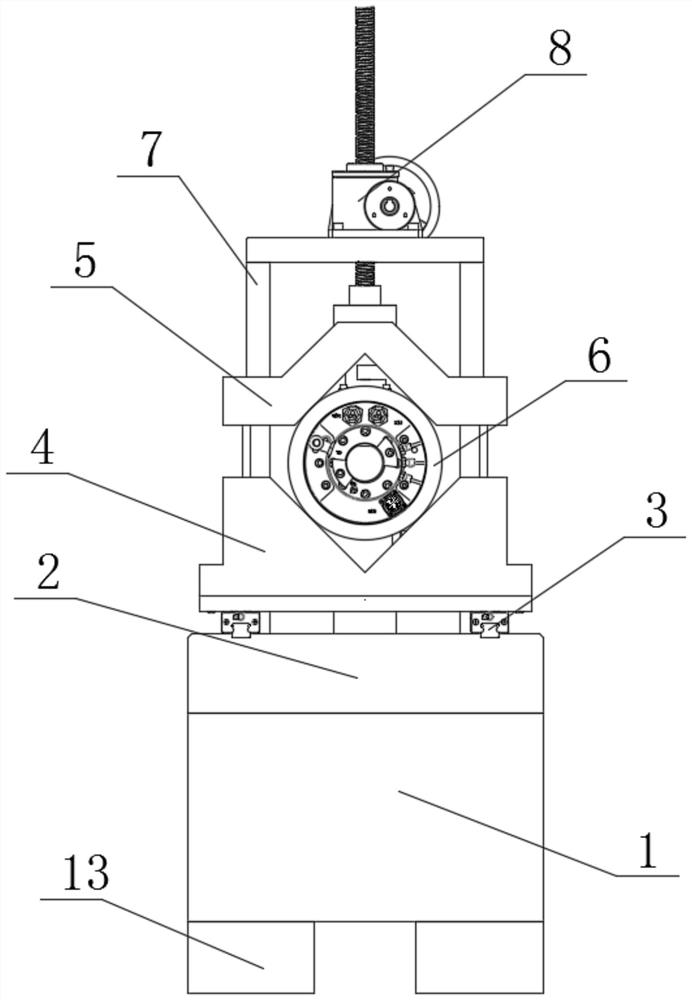

[0028] refer to Figure 1-5 , a platform for measuring the radial rigidity of the main shaft is proposed in this embodiment, including a platform 2, the bottom of the platform 2 is provided with a housing 1, and the top of the base 13 is fixed with a symmetrically arranged guide rail 3, and the number of guide rails 3 is two , the tops of the two guide rails 3 are slidingly connected with the same V-shaped base 4, the top of the V-shaped base 4 is slidably connected with a V-shaped buckle 5, the top of the V-shaped base 4 is provided with an auxiliary spindle 6, and the V-shaped base 4 is fixed to different sizes. The main shaft 6 of the rotating screw lifter 8 applies pressure to the hand wheel, and a dial indicator 37 is set below to detect the deformation. The top of the platform 2 is fixedly installed with a fixed frame 7, and the fixed frame 7 is fixedly installed with a screw screw lifter 8. The inboard of fixed frame 7 is fixedly equipped with dial indicator 37, is prov...

Embodiment 2

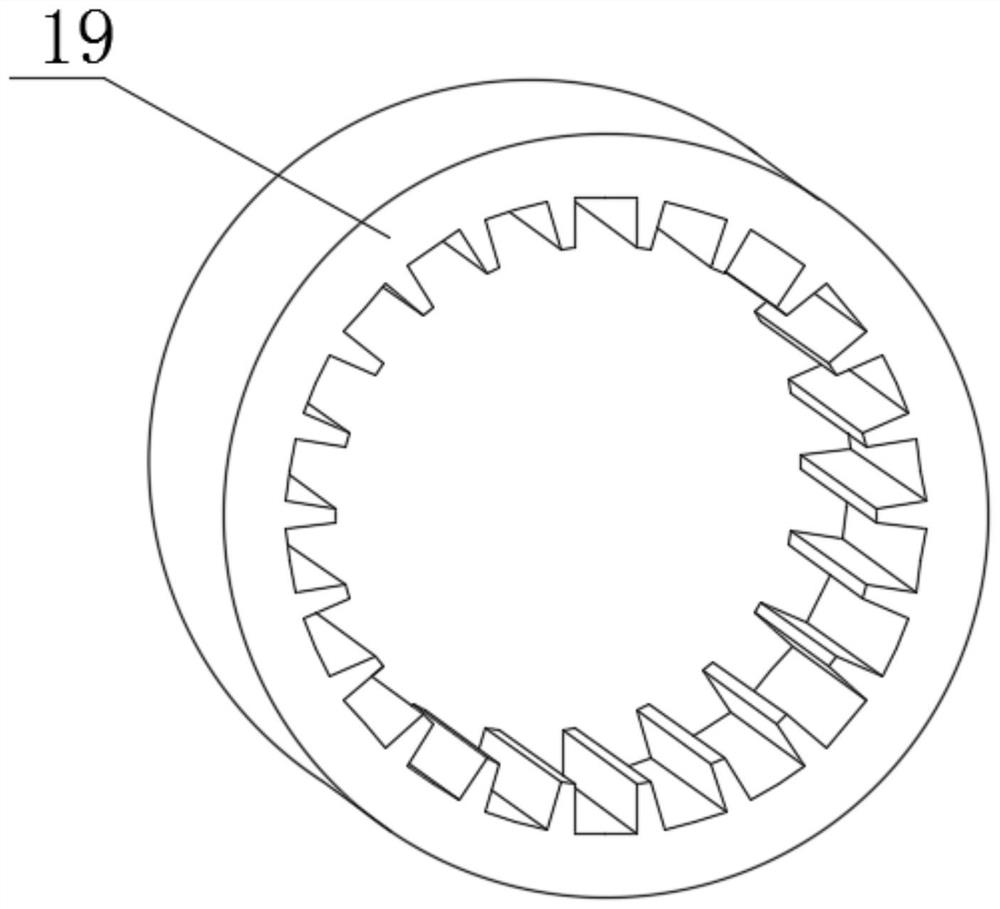

[0030]Power mechanism comprises motor 9, control lever 12, support 18, two connecting rings 19, two drive gears 20, push ring 21, pulling frame 22 and dial 39, motor 9 is fixedly installed on the inwall of shell 1, dial 39 is fixedly installed on the output shaft of the motor 9, and the two connecting rings 19 are connected to the bracket 18 in rotation, the control rod 12 is fixedly connected to the bracket 18 located on the right side, and the two driving gears 20 are fixedly connected to the two connecting rings 19 respectively , the push ring 21 is fixedly connected with the driving gear 20 at the lower position, and the pulling frame 22 is fixedly connected with the driving gear 20 at the upper position. 1, the top of the housing 1 is provided with a rectangular through hole, the bottom of the platform 2 is provided with a rectangular groove, and the outside of the pull frame 22 is in sliding contact with the inner wall of the rectangular through hole and the inner wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com