Superconducting wire rod, Roebel superconducting composite cable and weaving method of Roebel superconducting composite cable

A technology of superconducting wires and composite cables, which is applied in the direction of superconducting devices, superconducting/high-conducting conductors, and the usage of superconducting elements. The effect of uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

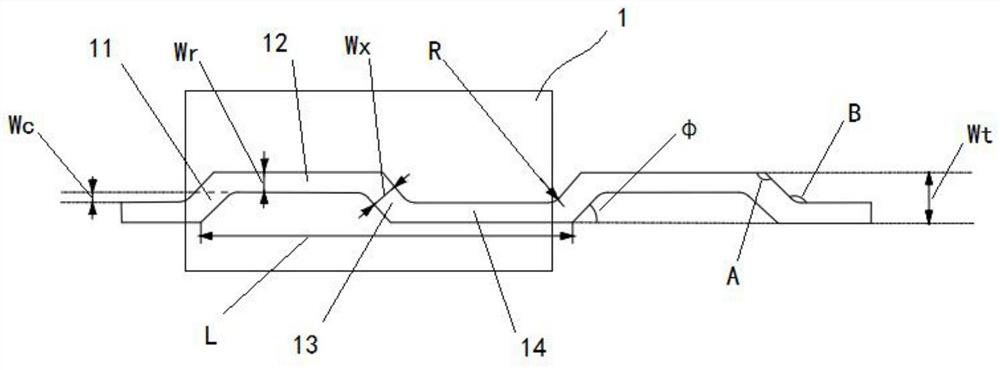

[0044] refer to Figure 1-2 , a superconducting wire, comprising a plurality of repeating units 1 connected in sequence, the plurality of repeating units 1 comprising a plurality of first repeating monomers and a plurality of second repeating monomers, the first repeating monomers and the second repeating monomers alternate setting;

[0045] The first repeating unit includes a first connecting section 11 and a first straight section 12, the first connecting section 11 and the first straight section 12 are arranged at an angle, and the first end of the first connecting section 11 is connected to the first straight section 12. first end connection;

[0046] The second repeating unit includes a second connecting section 13 and a second straight section 14, the second connecting section 13 and the second straight section 14 are arranged at an angle, and the first end of the second connecting section 13 is connected to the first straight section 12. The second end is connected; t...

Embodiment 2

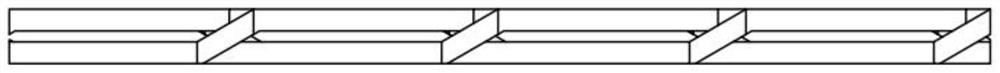

[0057] refer to Figure 3-Figure 12 , a Roebel superconducting composite cable, comprising the superconducting wires provided by N-strand embodiment 1, wherein the N-strands of superconducting wires are stacked sequentially, and the transposition period of the repeating unit of each superconducting wire is L, and each superconducting wire is The distance between the second end of the first connecting section of the wire and the second end of the first connecting section of the adjacent superconducting wire is L / N.

[0058] In this embodiment, the second end of the first connecting segment and the second end of the second straight segment of each strand of superconducting wire are respectively located at the lowermost end and the uppermost end of the Roebel superconducting composite cable within the transposition period of the repeating unit .

[0059] In this embodiment, the superconducting wire is an HTS sub-wire.

[0060] in, Figure 3 to Figure 12 , each of which shows p...

Embodiment 3

[0062] refer to Figure 11-Figure 20 , a braiding method of a Roebel superconducting composite cable, the braiding method provided in this embodiment is applicable to the braiding of the Roebel superconducting composite cable provided in Example 2, and the braiding method may further comprise the steps:

[0063] S30. Stack and place N single-strand superconducting wires in sequence, wherein the transposition period of the repeating unit of each superconducting wire is L, and the second end of the first connecting section of each superconducting wire is connected to its adjacent strand The distance between the second ends of the first connecting section of the superconducting wire is L / N.

[0064] S40. When weaving, the second end of the first connecting section and the second end of the second straight section of each superconducting wire are respectively located at the lowermost end and the uppermost end of the Roebel superconducting composite cable within the transposition p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com