Electric arc preventing method and transitional quencher with the same method

An arc extinguishing device and arc technology, applied in circuits, electrical switches, electrical components, etc., can solve the problems of elongation, difficulty in extinguishing arcs, and unsatisfactory effects, and achieve the effect of reducing contact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

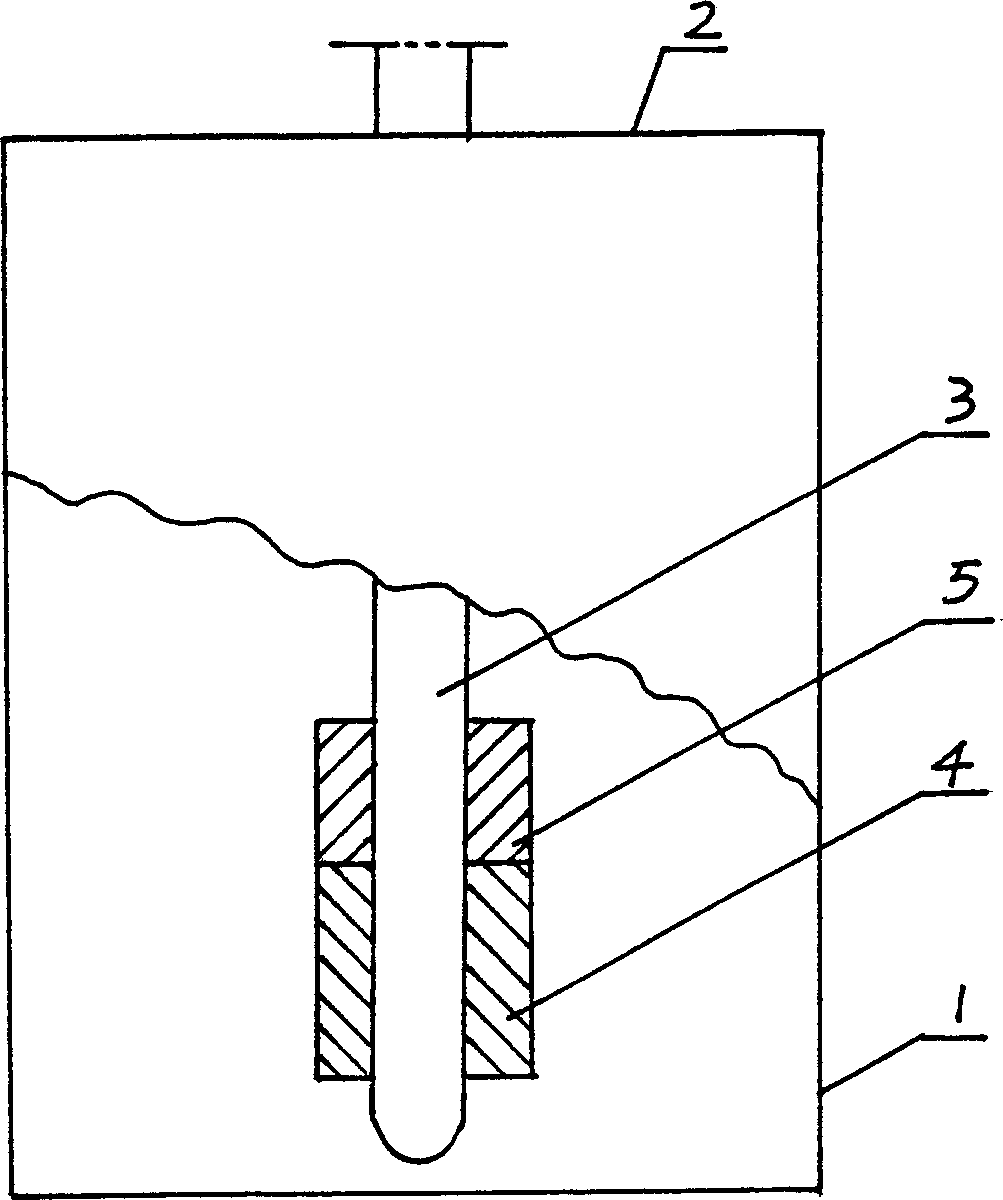

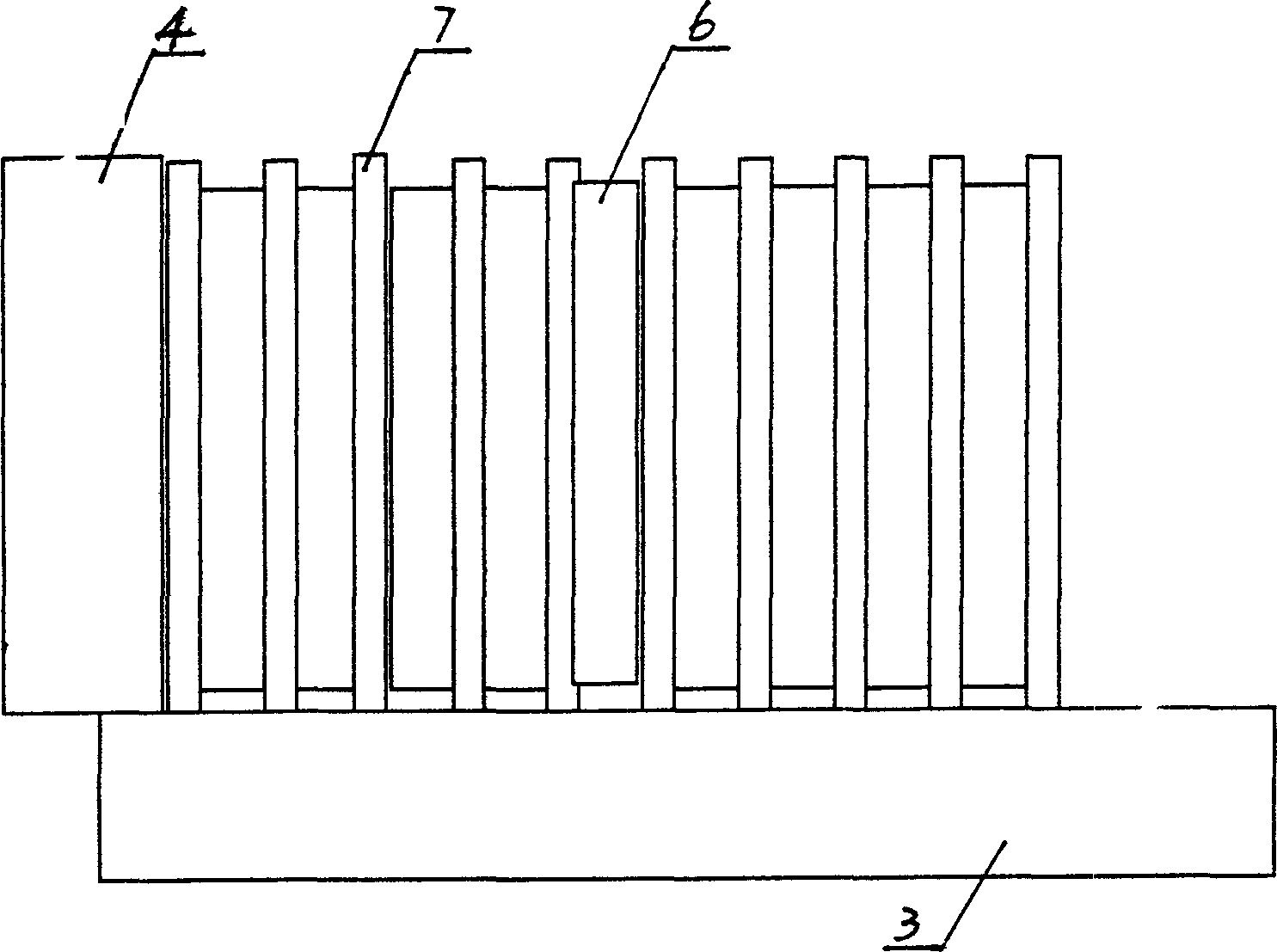

[0020] Embodiment 1: attached figure 1 Shown is a composite resistor extending across the stationary contacts. In the figure, the fuel tank 1 is provided with a fuel tank cover 2, and the movable contact 3 penetrates into the static contact 4, and a composite resistor 5 is extended on the upper part of the static contact 4, where the composite resistor 5 is cylindrical, and the composite resistor 5 is composed of multiple Resistor sheet 6 and equalizer sheet 7 are stacked at intervals (see image 3 ), the diameter of the flow equalizer 7 is longer than that of the resistance sheet 6, and when the moving and static contacts are separated, the flow equalizing sheet 7 is in contact with the moving contact respectively, that is, the compound resistance 5 is connected in series to the switch circuit for shunting, and the moving and static contacts are separated by the resistance sheet When the switch is completely disconnected, the connected resistance is the largest, and the curr...

Embodiment 2

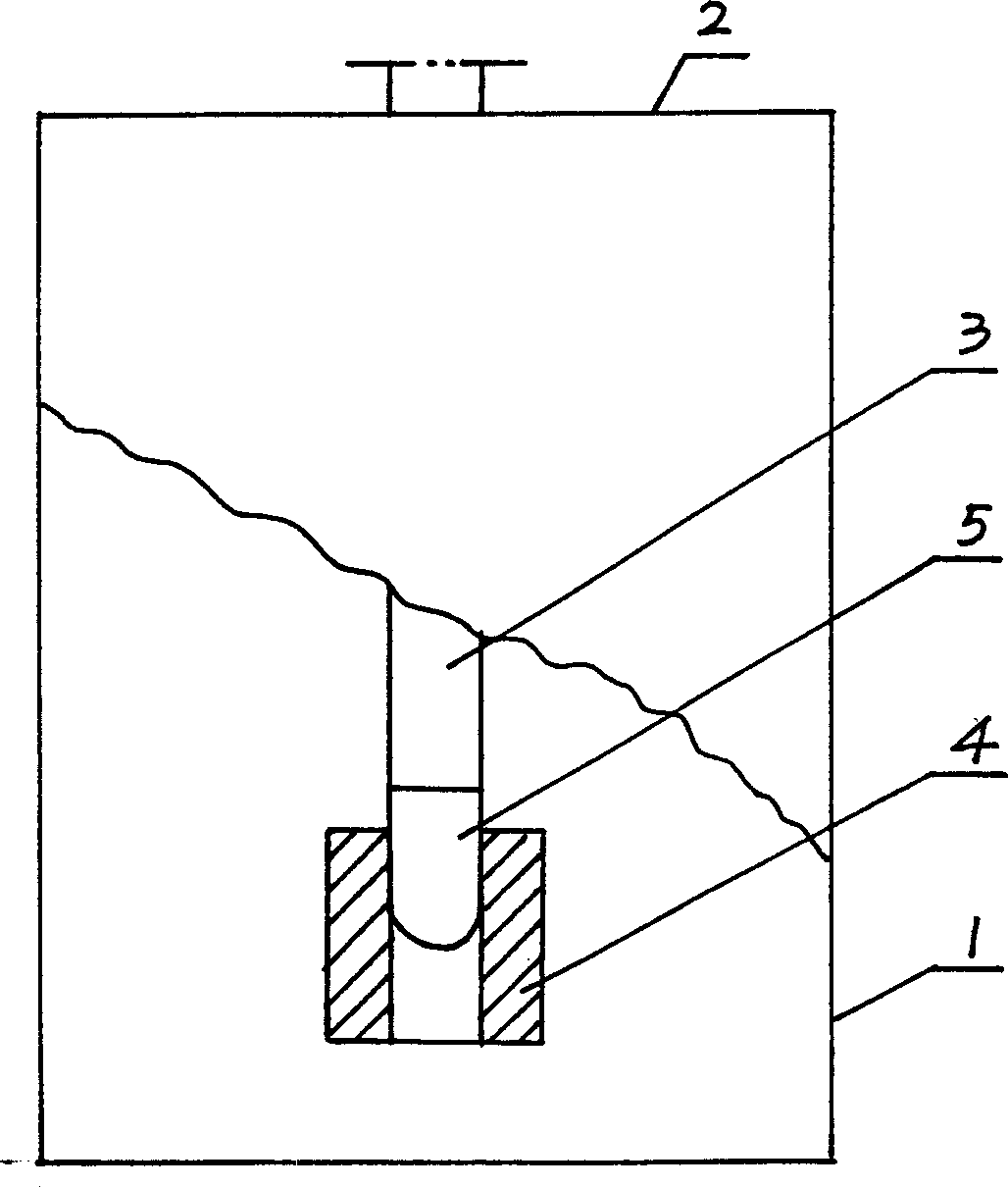

[0021] Embodiment 2: A cylindrical composite resistor 5 is extended on the moving contact 3 . The composite resistor 5 is also formed by stacking a plurality of resistive sheets 6 and current equalizers 7 at intervals. When the dynamic and static contacts are separated, the current equalizers 7 are respectively in contact with the static contacts 4, that is, the composite resistor 5 is connected in series to the switch circuit. Diverting, so as to achieve the purpose of high-efficiency arc extinguishing.

[0022] Both embodiment 1 and embodiment 2 are arc extinguishing by connecting composite resistors in series on the SN1-10 switch

Embodiment 3

[0023] Embodiment 3: see Figure 4 , is to connect the composite resistor in series on the composite switch used in the reactive power compensation cabinet to extinguish the arc. There are multiple static contacts 4 in the figure, and the conductive rod of the present invention is a movable contact 3, on which a composite resistor 5 is extended. A static contact 4, when the static contact 4 is completely disconnected from the movable contact 3, the composite resistor 5 has the largest contact area with the static contact 4, and the resistance is the largest, which can effectively prevent the generation of arc. Resistor 5 is square.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com