Device and method for detecting pressure resistance of building pipe

A detection device and pipe material technology, which is applied in the directions of measuring device, analyzing materials, and using stable tension/pressure to test the strength of materials, etc., can solve the problems of low detection efficiency, achieve improved anti-slip performance, accurate pressure resistance detection, and ensure no offset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] According to an embodiment of the present invention,

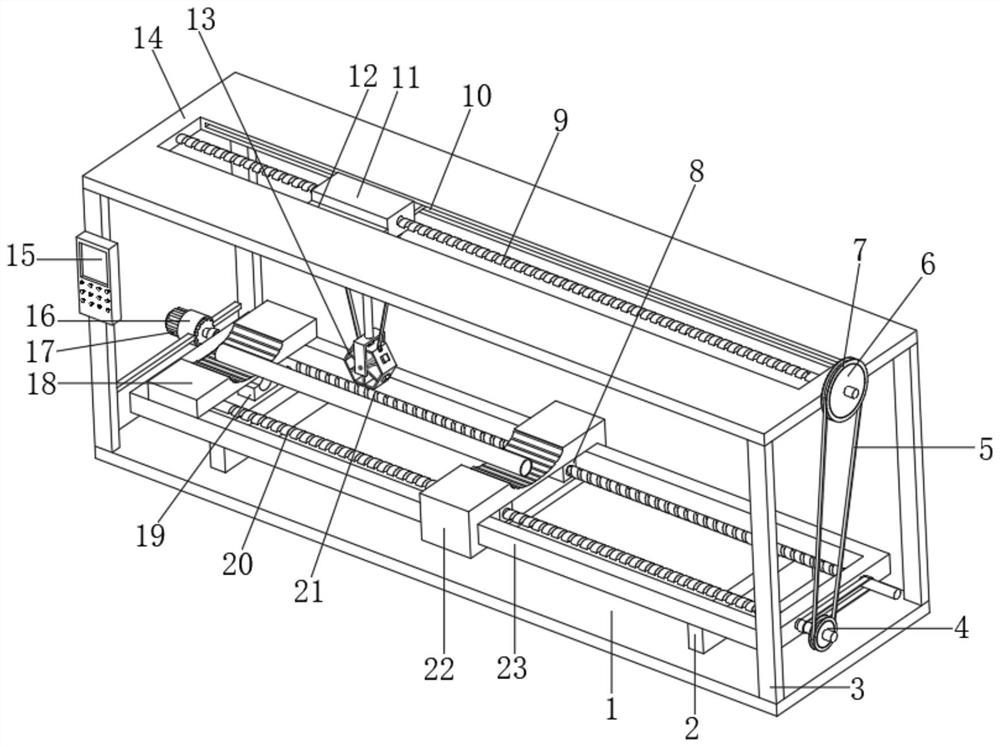

[0038] see Figure 1-7 , including the base plate 1 and the frame 23 located directly above the base plate 1, the opposite ends of the frame 23 and the base plate 1 are fixed with a support plate 2 by bolts, the frame 23 is installed with a moving adjustment mechanism, and the top of the base plate 1 The four corners of the outer wall are fixed with vertical columns 3 by bolts, and the top outer wall of the column 3 is fixed with the same top plate 14 by bolts. , the inner walls of both ends of the top notch are connected with the same top screw 9 through the bearing rotation, and the outer wall of one end of the top screw 9 is connected with a movable top block 11 through threads, and the inner walls of both sides of the top notch are provided with side grooves 10, and Both outer walls of the top plate 14 are welded with side slide plates 12 that are slidably connected to the side grooves 10, and the bottom outer ...

Embodiment 2

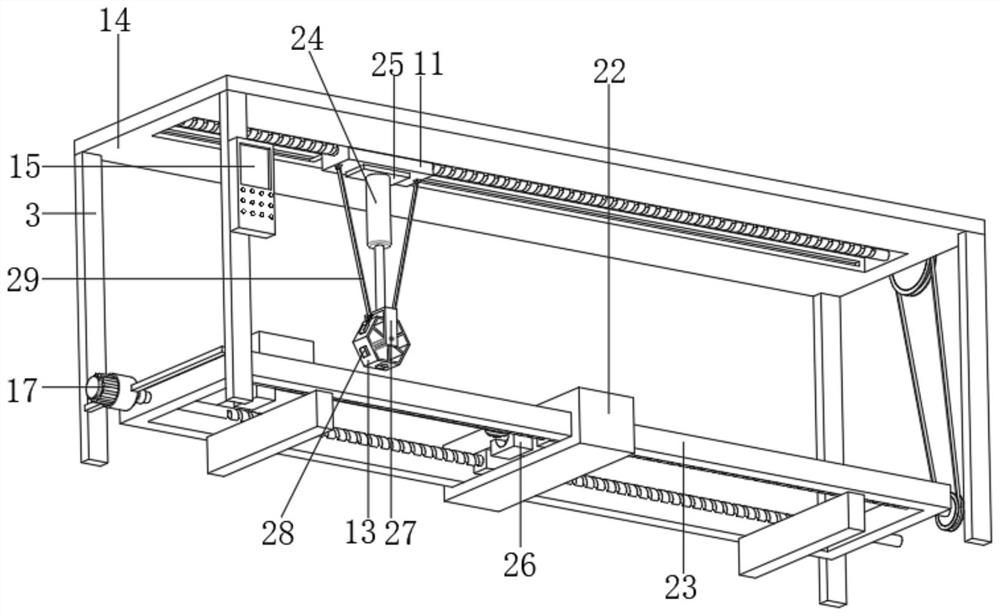

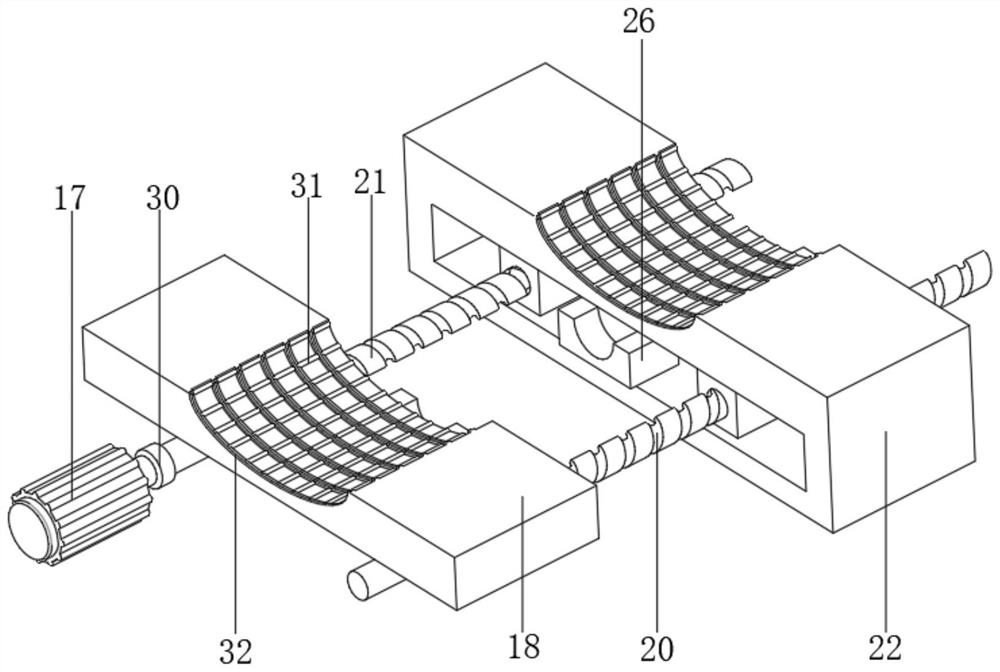

[0041] see figure 1 , figure 2 , Figure 4 , the adjustable extrusion mechanism includes a pressure sensor one 25 fixedly installed on the bottom outer wall of the moving top block 11, and the bottom end of the pressure sensor one 25 is fixedly installed with a hydraulic top rod 24, and the end of the extension rod of the hydraulic top rod 24 is fixed by bolts There is a U-shaped frame 27, and the U-shaped frame 27 is rotatably connected with a shaft through a bearing, the outer wall of the shaft is keyed with an inner connecting rib 33, and the end of the inner connecting rib 33 is fixed with the same hexagonal turret 13 by bolts , the outer wall of the hexagonal turret 13 is welded with arc groove pressing blocks 28, and the length of the arc groove pressing blocks 28 increases in turn. Both sides of the outer wall of the bottom are connected with fixed connecting rods 29 through hinges, and the ends of the fixed connecting rods 29 are provided with connecting holes match...

Embodiment 3

[0044] see Figure 1-2 , the opposite side of one end of the column 3 is fixed with a clamp rod 16 by bolts, and the inner wall of the clamp rod 16 is fixedly installed with a drive motor 17, and the output shaft of the drive motor 17 is fixedly connected with a torque sensor 30, and the other side of the torque sensor 30 is fixed. One end is fixedly connected with the second threaded screw rod 21 , and the control panel 15 is fixed with bolts on the side of the column 3 close to the clamp rod 16 .

[0045] The torque sensor 30 provided can provide the torque when the driving motor 17 operates, increase the types of detection data, and improve the detection accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com