Pit pressure folding resistance detection equipment for new material

A technology for testing equipment and new materials, applied in the direction of analyzing materials, testing material strength by applying stable bending force, testing material strength by applying stable tension/pressure, etc. It can solve the problem of moving new materials and not being able to pit new materials Compression and folding test and other issues to achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

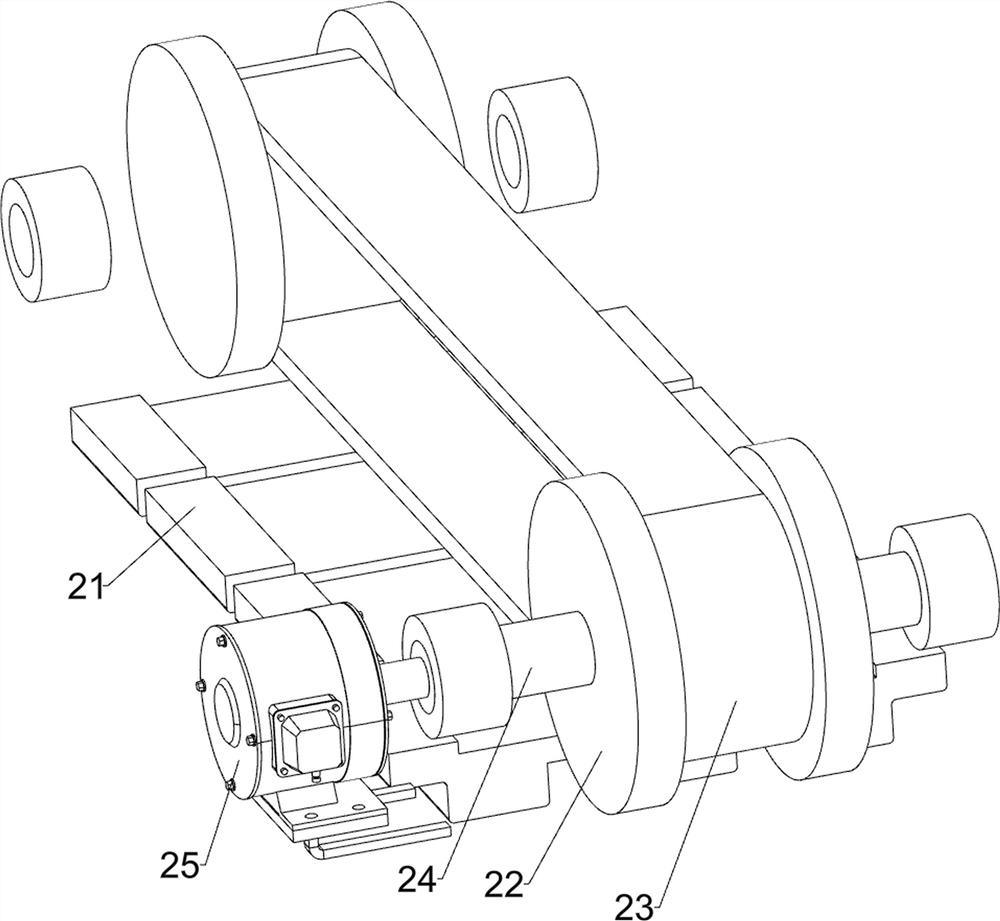

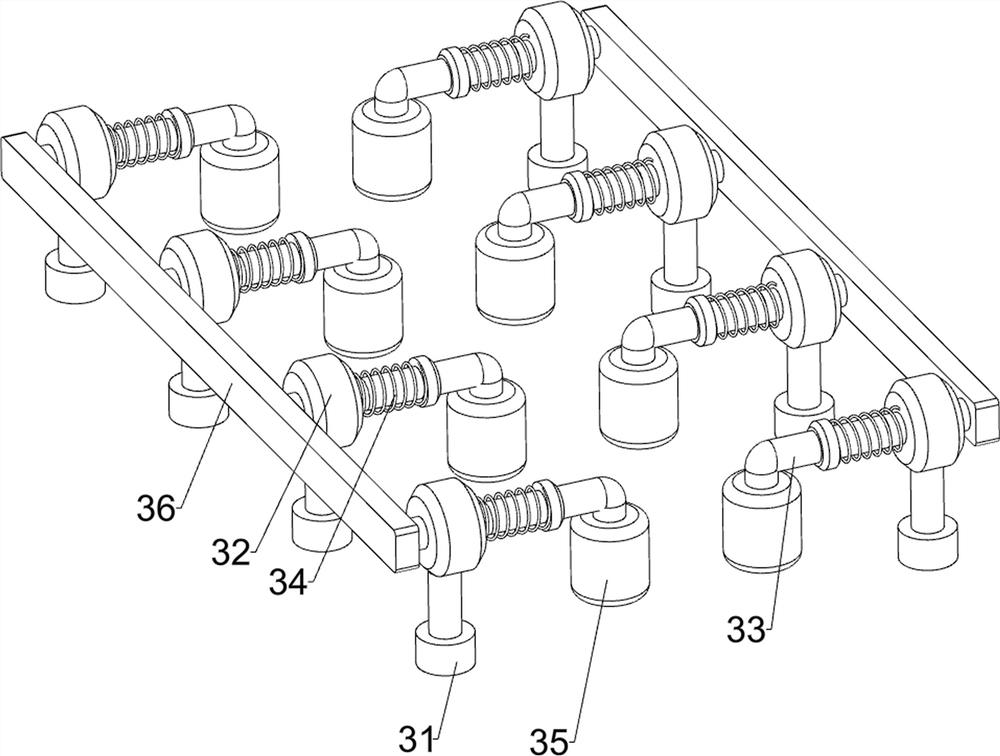

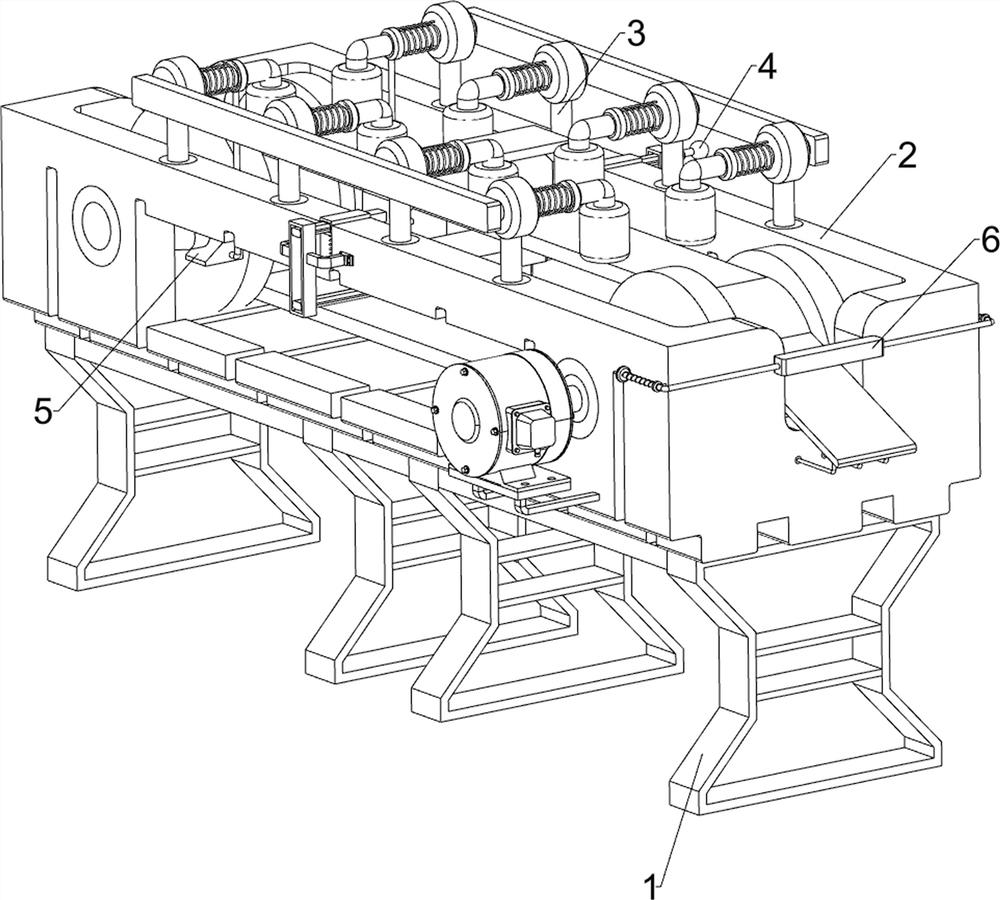

[0022] Pit pressure and folding test equipment for a new material, such as Figure 1-Figure 6 As shown, it includes a base 1, a transmission component 2, a compression component 3 and a bending component 4. The base 1 is used to install the entire device. The upper part of the base 1 is provided with a transmission component 2 that provides power for transmission. A compression component 3 that resists compression by sliding, and a bending component 4 that bends by sliding is provided in the middle of the transmission component 2 .

[0023] When a new material needs to be inspected, the staff first places the new material on the conveying component 2, and then starts the conveying component 2 to transmit the new material. At the same time, the new material and the bending component 4 are continuously inspected, and then When the material is moved to an appropriate position, the staff moves the bending assembly 4 to monitor the compression resistance of the new material. When t...

Embodiment 2

[0031] On the basis of Example 1, such as figure 1 and Figure 5 As shown, it also includes a push assembly 5, the push assembly 5 includes a push block 51, a connecting rod 52 and a wedge block 53, the rotating rod 24 is provided with a push block 51, there are two connecting rods 52, and the rightmost L-shaped The bottom of the bar 33 is welded with a connecting rod 52, and the tail end of the connecting rod 52 is fixedly connected with a wedge-shaped block 53 by screws, and the push block 51 cooperates with the wedge-shaped block 53.

[0032] When the rotating rod 24 rotates, it drives the push block 51 to rotate, pushes the wedge block 53 to move inwardly, drives the connecting rod 52 to move inwardly, and then drives the L-shaped bar 33 to move inwardly. When the push block 51 and the wedge block 53 are separated, Under the action of the L-shaped rod 33, the connecting rod 52 and its upper device are moved outwards and reset, so that the new material can be automatically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com