Carton manufacturing and conveying device

A conveying device and carton technology, applied in transportation and packaging, box making operations, packaging, etc., can solve problems such as slipping, cardboard cannot be conveyed, and it is difficult to ensure the delivery of a single piece of cardboard, so as to promote the falling of cardboard and improve the effect of conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

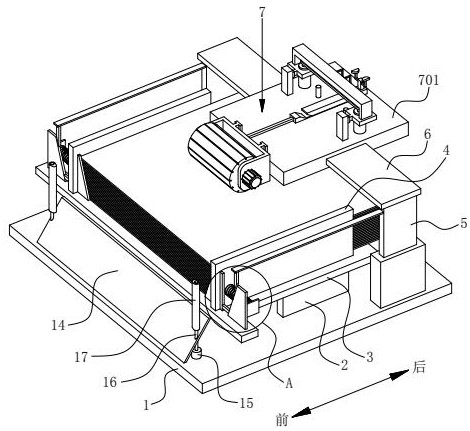

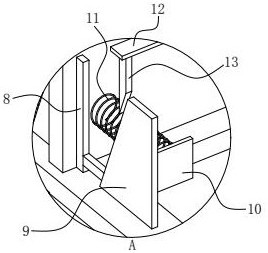

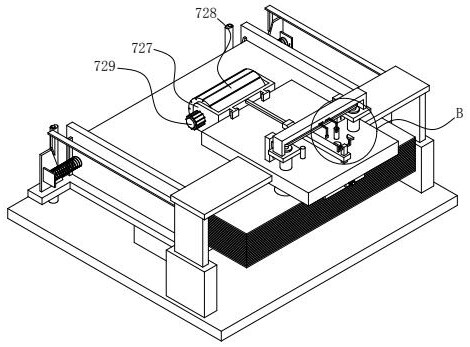

[0027] like figure 1 As shown, the present embodiment provides a carton making and conveying device, comprising a horizontal base plate 1, a plurality of support plates 2 are fixedly installed on the upper surface of the base plate 1, and a horizontal support plate 3 is fixedly installed on the top of the plurality of support plates 2. , the upper surface of the support plate 3 is vertically fixed with two limit plates 4, and the two limit plates 4 are arranged in the front and rear directions, and the upper surface of the bottom plate 1 is located on the left and right sides of the support plate 3. The telescopic plate 5 and the telescopic section end of the electric telescopic plate 5 are fixedly installed with a horizontal lifting plate 6 , and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com