Textile fabric dyeing device facilitating fabric taking

A technology for textile fabrics and dyeing devices, which is applied in the direction of textile material processing equipment configuration, textile material processing, and textile material carrier processing, which can solve time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

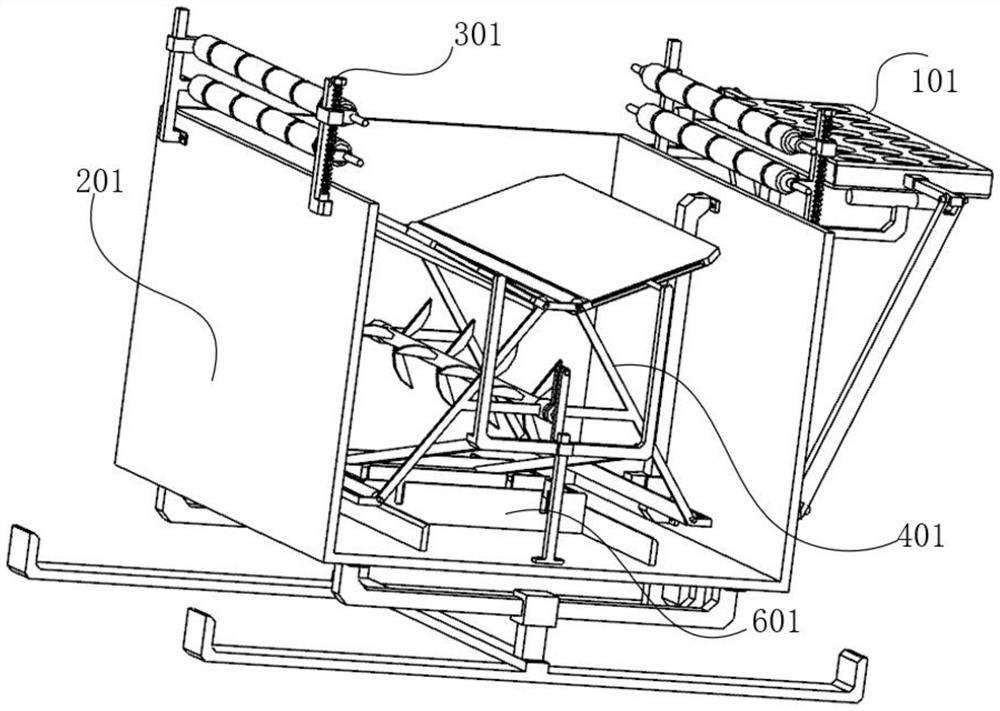

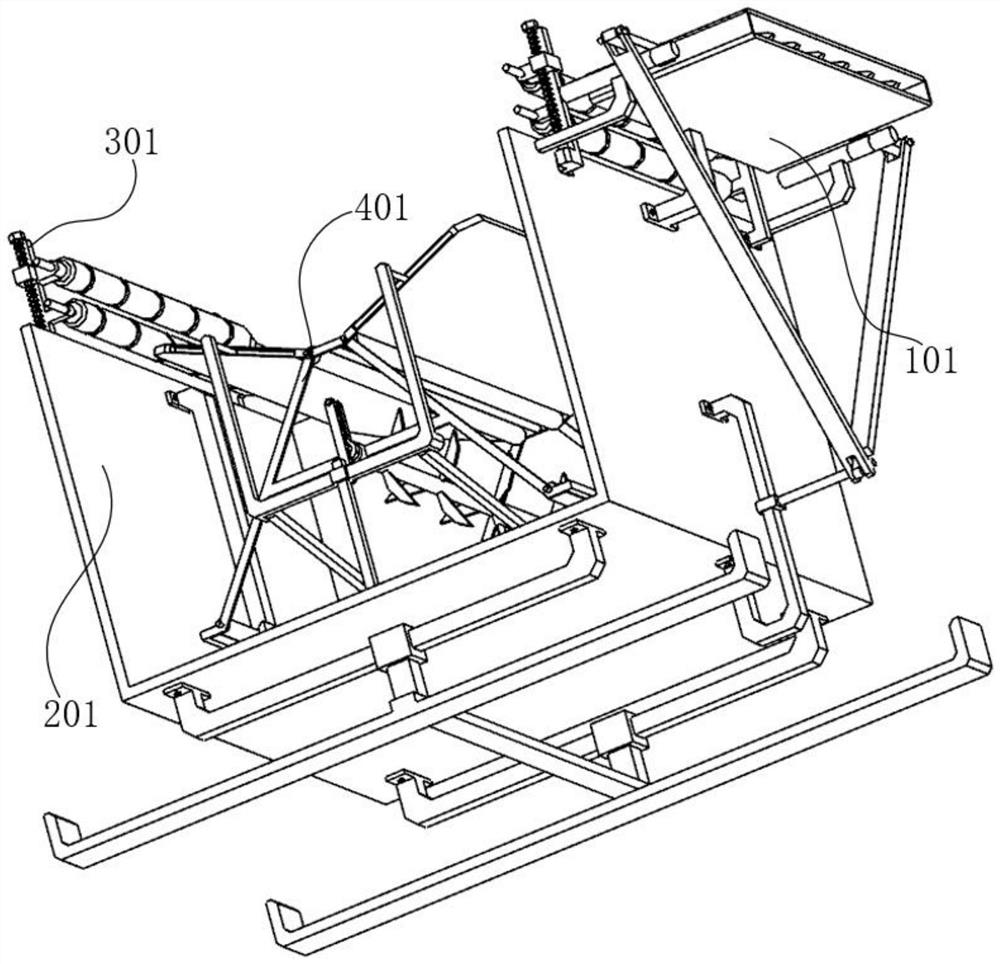

[0023] Such as Figure 1-5 As shown, this example solves the problem of quickly tie-dyeing cloth,

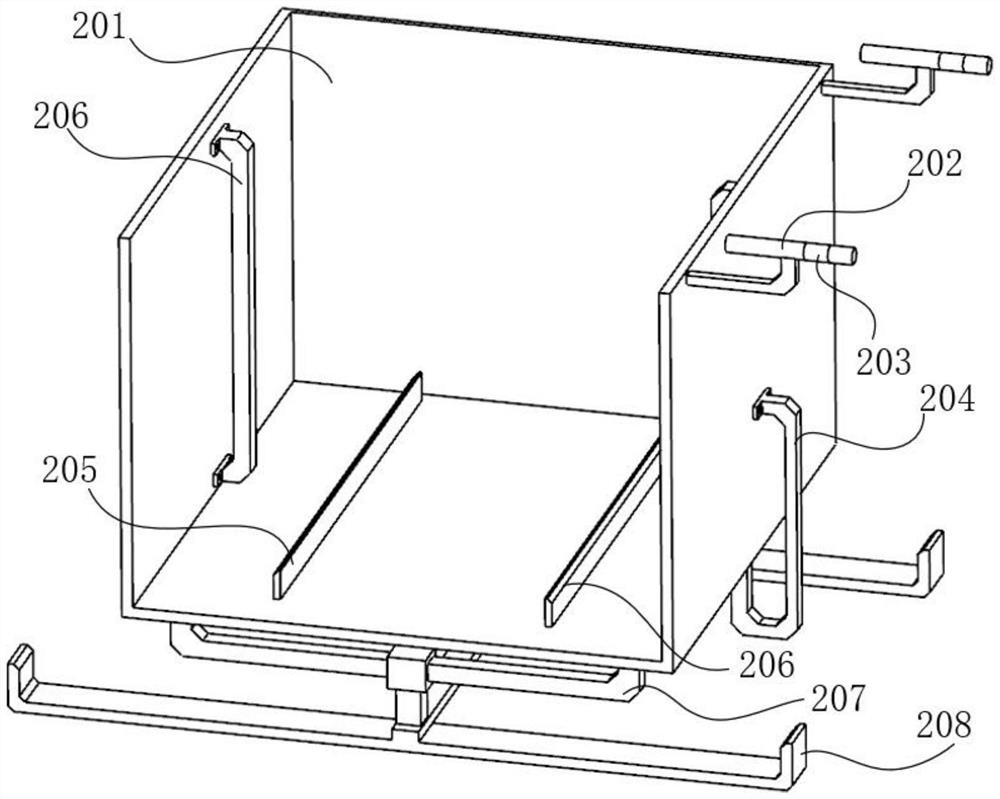

[0024] Because the textile cloth dyeing device that is convenient to take cloth comprises tie-dye box 101, tie-dye push rod 102, tie-dye box connecting rod 103, tie-dye rotating rod 104, tie-dye slide bar 105, dip-dye box 201 and tie-dye slideway 204, One end of the tie-dye box connecting rod 103 is fixedly connected to the tie-dye box 101, and the other end is connected to the dip-dye box 201. Two tie-dye push rods 102 are respectively laterally slidably connected to the two ends of the tie-dye box 101. The tie-dye push rods (102) Composed of arc-shaped push plates and rods, two tie-dye rotating rods 104 are respectively connected in rotation with two tie-dye push rods 102, and tie-dye sliding rods 105 are connected in rotation with the lower ends of the two tie-dye push rods 102. Road 204 is connected with the lower side of tie-dyeing box 101, and tie-dyeing slide bar 105 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com