A ceramic packaging equipment

A technology for packaging equipment and ceramics, applied in the field of ceramic packaging equipment, can solve the problems of low efficiency of ceramic packaging, damage to ceramics, etc., and achieve the effects of saving labor costs, improving density, and improving packaging speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will now be further described with reference to the accompanying drawings and specific embodiments.

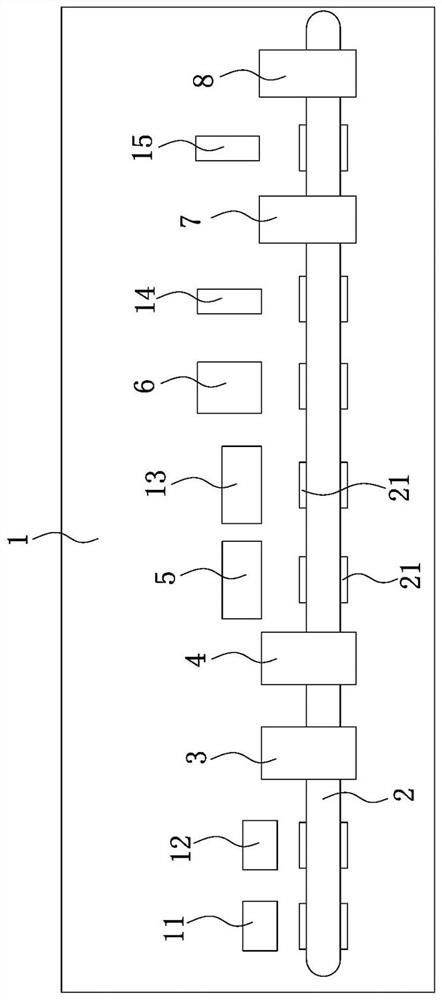

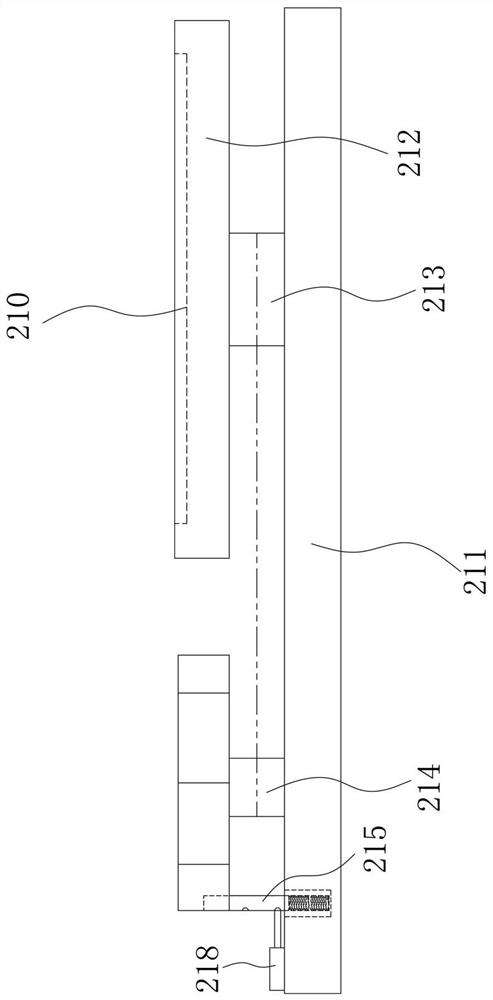

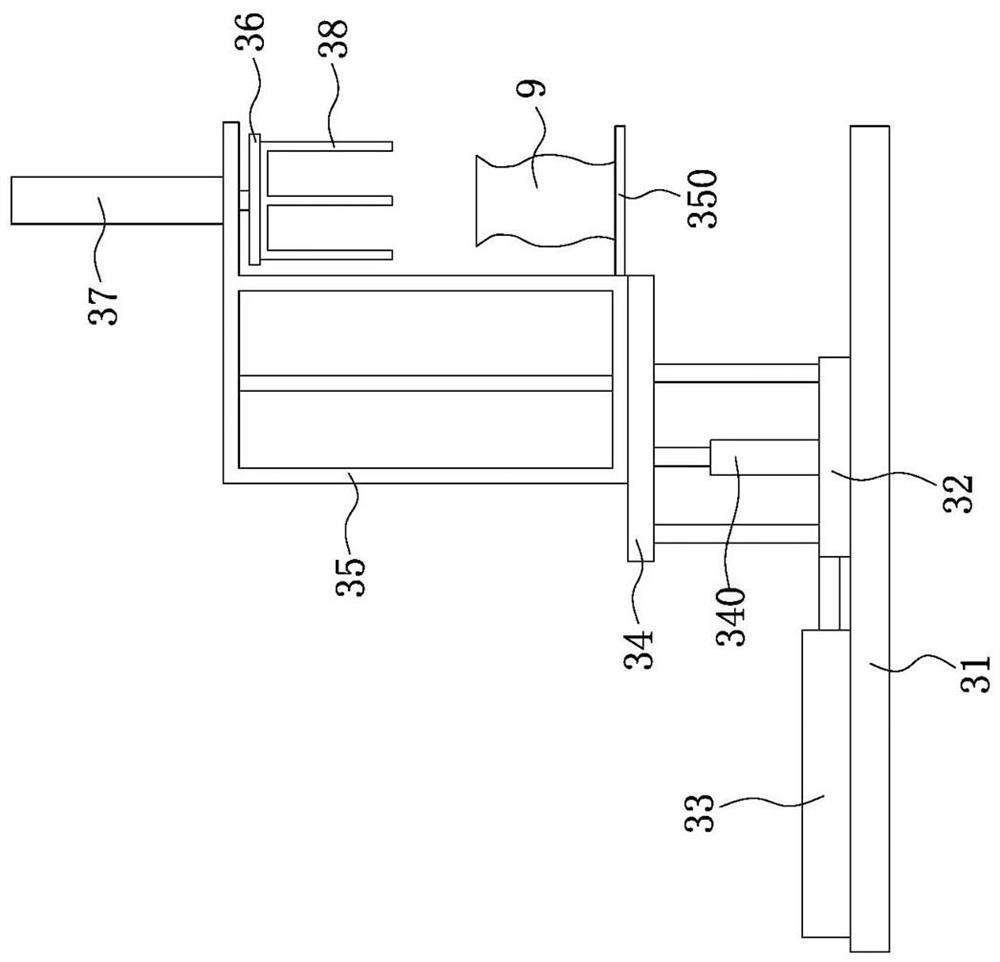

[0047] refer to Figure 1 to Figure 16 , this embodiment provides a ceramic packaging equipment, including a frame 1, a conveying mechanism 2 arranged on the frame 1, the frame 1 is sequentially provided with a bottom box mechanism 11 and a bottom foam placing mechanism 12 along the direction of the conveying mechanism 2 , Placement mechanism 3, side foam placement mechanism 4, top foam placement mechanism 5, top box mechanism 13, cotton injection mechanism 6, first sealing mechanism 14, rotating mechanism 7, pressing mechanism 15, second sealing mechanism 8.

[0048] The packaging box includes a bottom box 91 and a top box 92. The bottom box 91 is provided with a slot 911 and a positioning slot 912; the lower end of the top box 92 can be inserted into the slot 911; the slot 911 of the bottom box 91 is respectively provided with a first card A slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com