Air purifier based on electrostatic dust collection technology

An air purification equipment and electrostatic dust collection technology, applied in the field of air purification, can solve problems affecting the performance of the whole machine, assembly, connection and sealing of easily damaged fans, and fans with easy to wear wires, so as to overcome corrosion problems, reduce weight, and avoid The effect of bumping or even damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

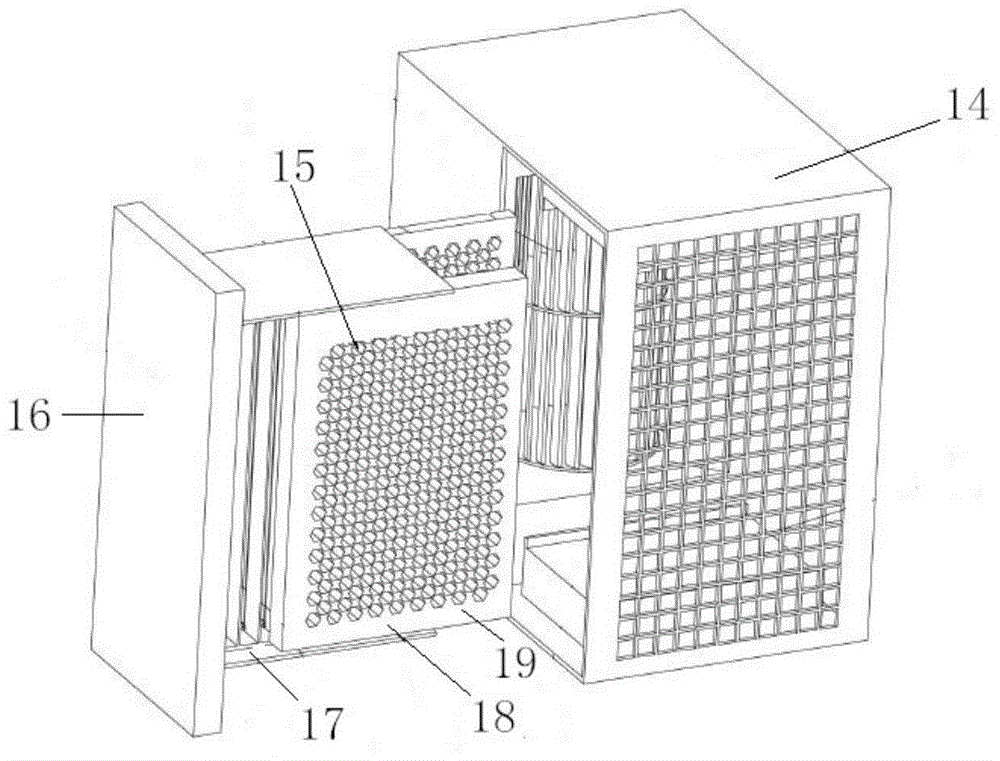

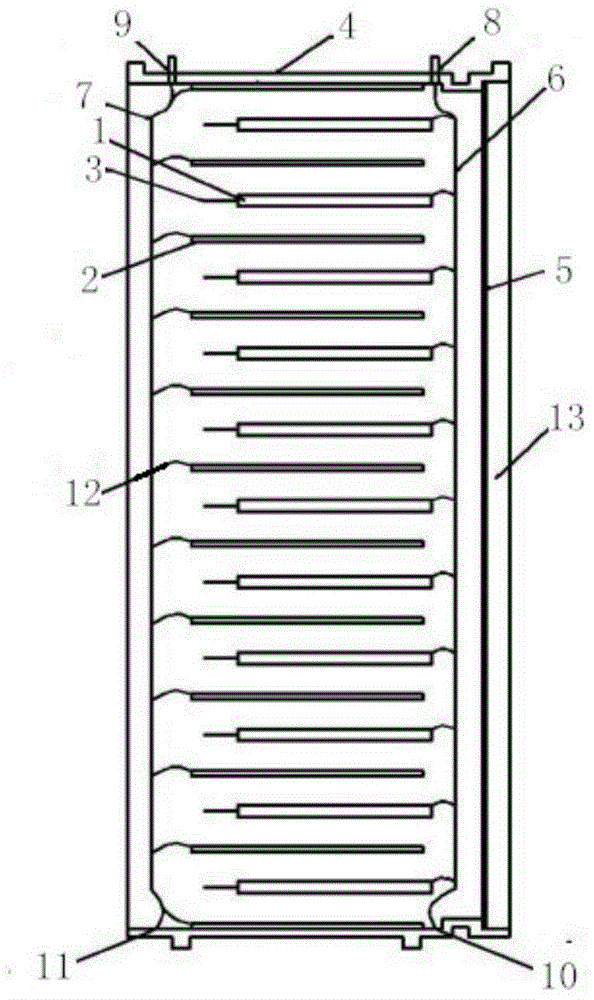

[0020] An air purification device based on electrostatic dust collection technology, comprising a housing 14, a purification component 15 is arranged inside the housing 14, the purification component 15 is fixedly connected with a movable side wall 16, and the purification component 15 includes a positive plate 1, a negative plate 2, Discharge needle 3, inner shell 4, back pressure back plate 5, first wire 6, second wire 7, positive spring connector 8, negative spring connector 9, positive connector 10, negative connector 11, air inlet 12, air outlet 13 , the positive plate 1 and the negative plate 2 are horizontally arranged in a staggered manner in the casing 4 and are located on the side of the air inlet 12, the discharge needle 3 is fixed on the side of the air inlet 12, and a dust collecting area is formed between the positive plate 1 and the negative plate 2, The dust collection area is connected with the air outlet 13, and the back pressure back plate 5 is installed at t...

Embodiment 2

[0022] An air purification device based on electrostatic dust collection technology, comprising a housing 14, a purification component 15 is arranged inside the housing 14, the purification component 15 is fixedly connected with a movable side wall 16, and the purification component 15 includes a positive plate 1, a negative plate 2, Discharge needle 3, inner shell 4, back pressure back plate 5, first wire 6, second wire 7, positive spring connector 8, negative spring connector 9, positive connector 10, negative connector 11, air inlet 12, air outlet 13 , the positive plate 1 and the negative plate 2 are horizontally arranged in a staggered manner in the casing 4 and are located on the side of the air inlet 12, the discharge needle 3 is fixed on the side of the air inlet 12, and a dust collecting area is formed between the positive plate 1 and the negative plate 2, The dust collection area is connected with the air outlet 13, and the back pressure back plate 5 is installed at t...

Embodiment 3

[0025] An air purification device based on electrostatic dust collection technology, comprising a housing 10, a purification component 30 is arranged inside the housing 10, the purification component 30 is fixedly connected with a movable side wall 20, and the purification component 30 includes a positive plate 1, a negative plate 2, Discharge needle 3, inner shell 4, back pressure back plate 5, first wire 6, second wire 7, positive spring connector 8, negative spring connector 9, positive connector 10, negative connector 11, air inlet 12, air outlet 13 , the positive plate 1 and the negative plate 2 are horizontally arranged in a staggered manner in the casing 4 and are located on the side of the air inlet 12, the discharge needle 3 is fixed on the side of the air inlet 12, and a dust collecting area is formed between the positive plate 1 and the negative plate 2, The dust collection area is connected with the air outlet 13, and the back pressure back plate 5 is installed at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com