Empirical mode guided-mode oriented crystallization device and growth method based on oriented mode guided-mode oriented crystallization device

A technology of directional crystallization and guided mode method, which is applied in the direction of single crystal growth, crystal growth, chemical instruments and methods, etc., can solve the problems of difficult growth of high melting point oxide crystals, high quality of grown crystals, and difficult cleaning of crucibles, etc. Economic use value, high crystal quality, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

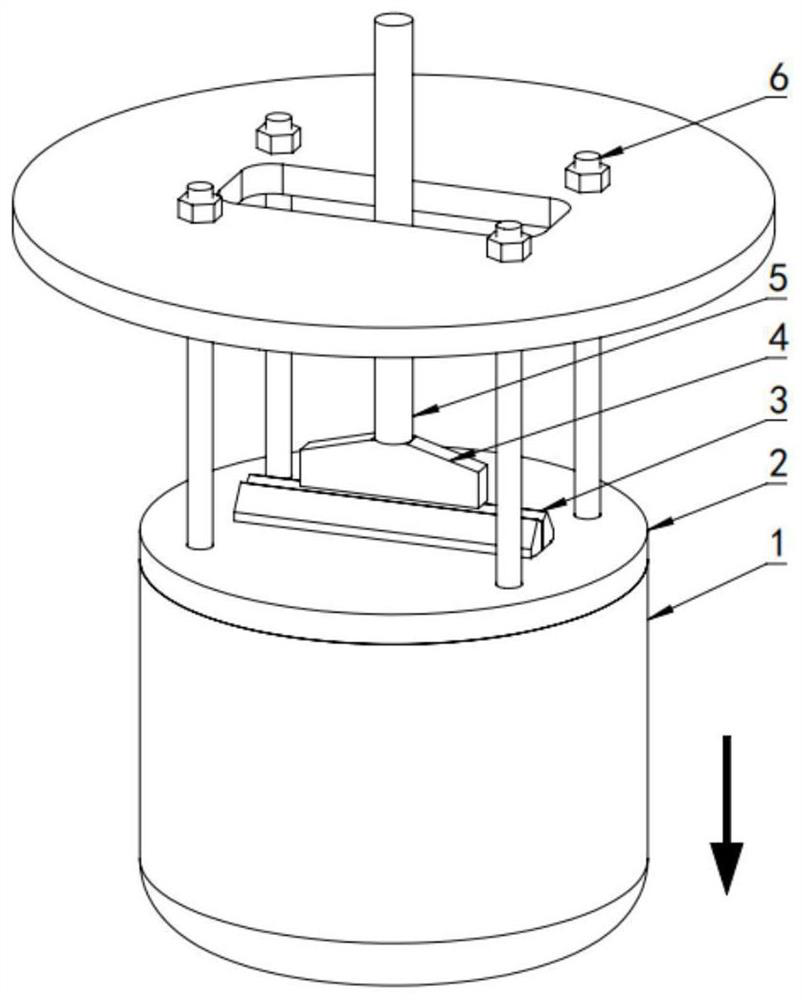

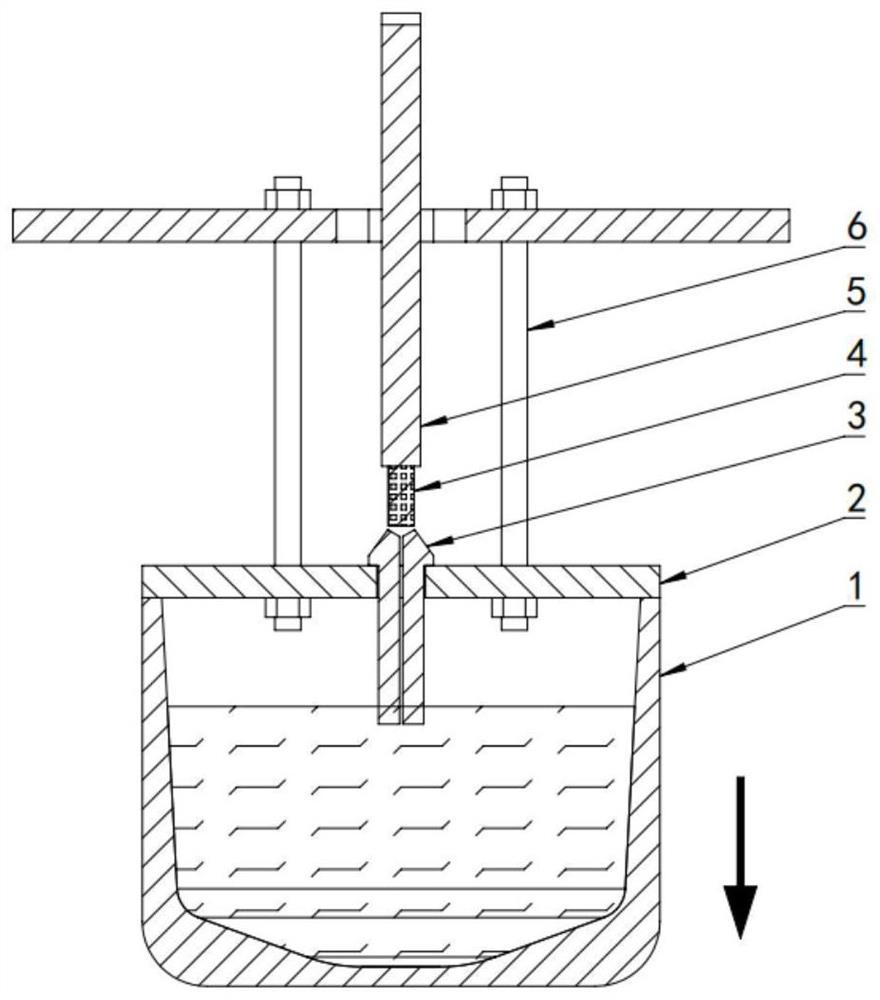

[0046] Gadolinium scandate (GdScO 3 ) The growth process of the single crystal is as follows: Gd with a purity of 99.99% 2 O 3 with Sc 2 O 3The raw materials are accurately weighed according to the stoichiometric ratio, mixed uniformly, pressed isostatically at 200MPa, put into an alumina crucible and sintered at 1500℃ for 10h; put the sintered raw materials into the iridium crucible, and select the gap width of the capillary channel A 0.4mm mold is placed on the crucible cover, such as figure 1 As shown, GdScO is placed in the die mouth 3 Grain; crucible cover is lifted by molybdenum suspension rod, and is not stressed by crucible; GdScO in (100) direction is selected 3 The seed crystal is fixed on the seed rod chuck; the furnace door is closed, the mechanical pump is turned on for vacuuming, when the vacuum degree reaches 5Pa, the mechanical pump is turned off, and the protective gas is charged to the standard atmospheric pressure; Completely melt; continue to heat up ...

Embodiment 2

[0048] 1.0% Ho:Lu in this example 2 O 3 The growth process of the single crystal is as follows: the purity of 99.99% Lu 2 O 3 with Ho 2 O 3 The raw materials are accurately weighed according to the stoichiometric ratio, mixed evenly, pressed under isostatic pressing at 200 MPa, put into an alumina crucible and sintered at 1600 °C for 10 hours; The mold of mm is placed on the crucible cover, and the mold mouth is placed with Lu 2 O 3 Grain; the crucible cover is lifted by the molybdenum suspension rod and is not stressed by the crucible; choose Lu in the (100) direction 2 O 3 The seed crystal is fixed on the seed rod chuck; the furnace door is closed, the mechanical pump is turned on for vacuuming, when the vacuum degree reaches 8Pa, the mechanical pump is turned off, and the protective gas is charged to the standard atmospheric pressure; Completely melted; continue to heat up to 30 °C, shake the seed crystals after the pellets at the die mouth begin to melt, and keep t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com