Method and system for testing automobile hybrid power system

A technology of a hybrid power system and a testing method, which is applied in the testing of vehicles, testing of machine/structural components, measuring devices, etc., can solve the problems of shortening the life of the cooling system, easy dispersion of the cooling coefficient, and unfavorable stable operation of the cooling system, etc. High stability and life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purposes, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be introduced below with reference to the accompanying drawings in the embodiments of the present invention.

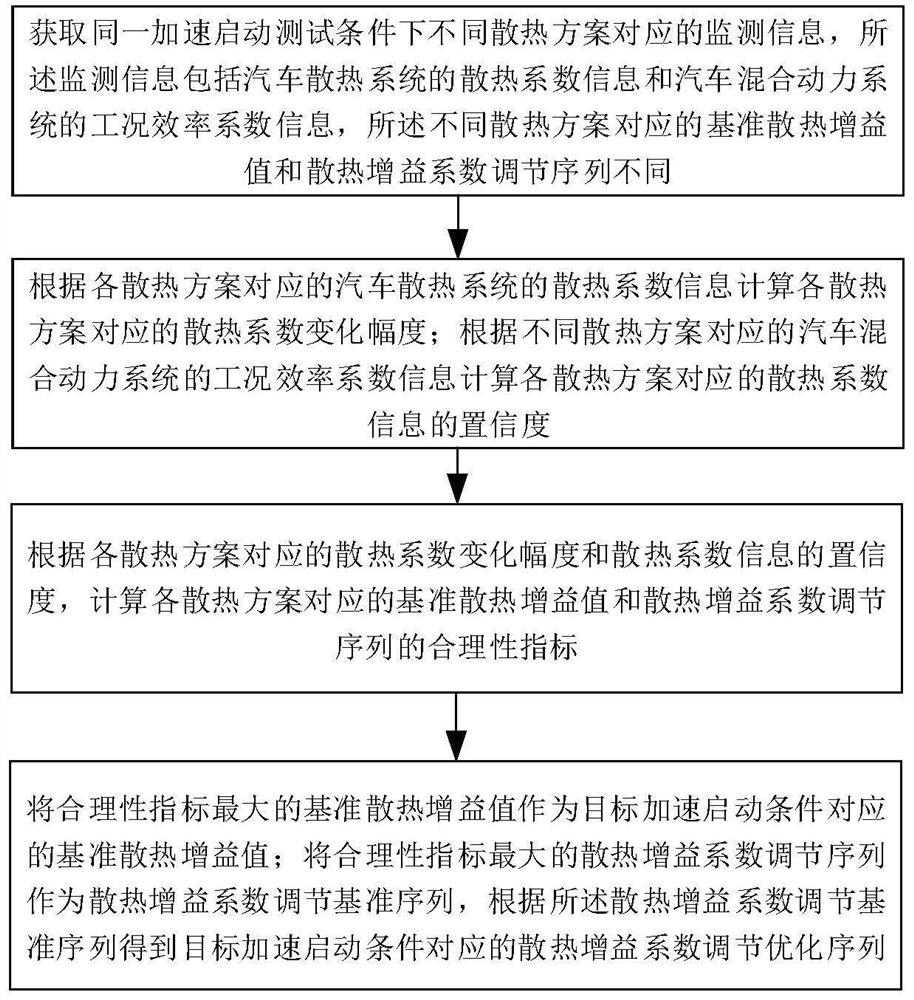

[0034] like figure 1 As shown, the testing method of the vehicle hybrid power system of this embodiment includes the following steps:

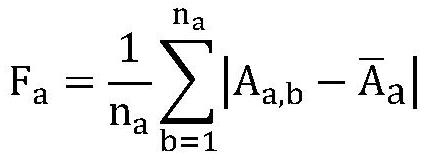

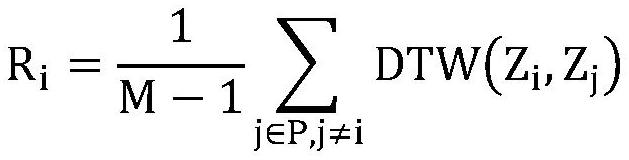

[0035] (1) Obtain the monitoring information corresponding to different heat dissipation schemes under the same accelerated start test condition, the monitoring information includes the heat dissipation coefficient information of the automobile heat dissipation system and the working condition efficiency coefficient information of the automobile hybrid power system, and the benchmark corresponding to the different heat dissipation schemes The heat dissipation gain value and the heat dissipation gain coefficient adjustment sequence are diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com