Novel rail web ink-jet printer

A technology of inkjet printer and rail waist, which is applied in the field of rails, can solve the problems of troublesome transportation and installation, inconvenient use, time-consuming and laborious, etc., and achieve the effects of convenient transportation and installation, easy recycling, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

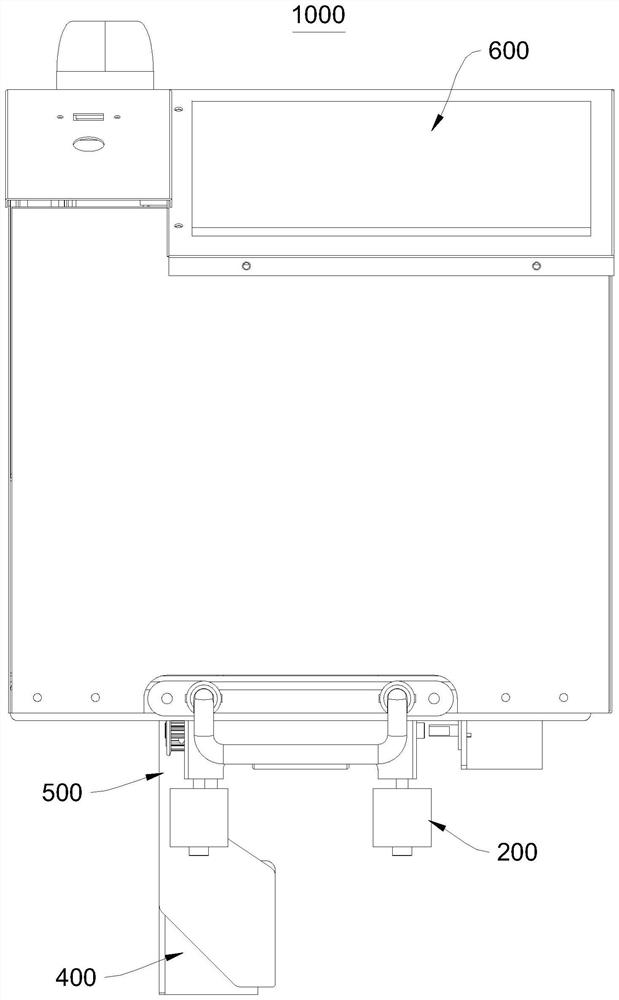

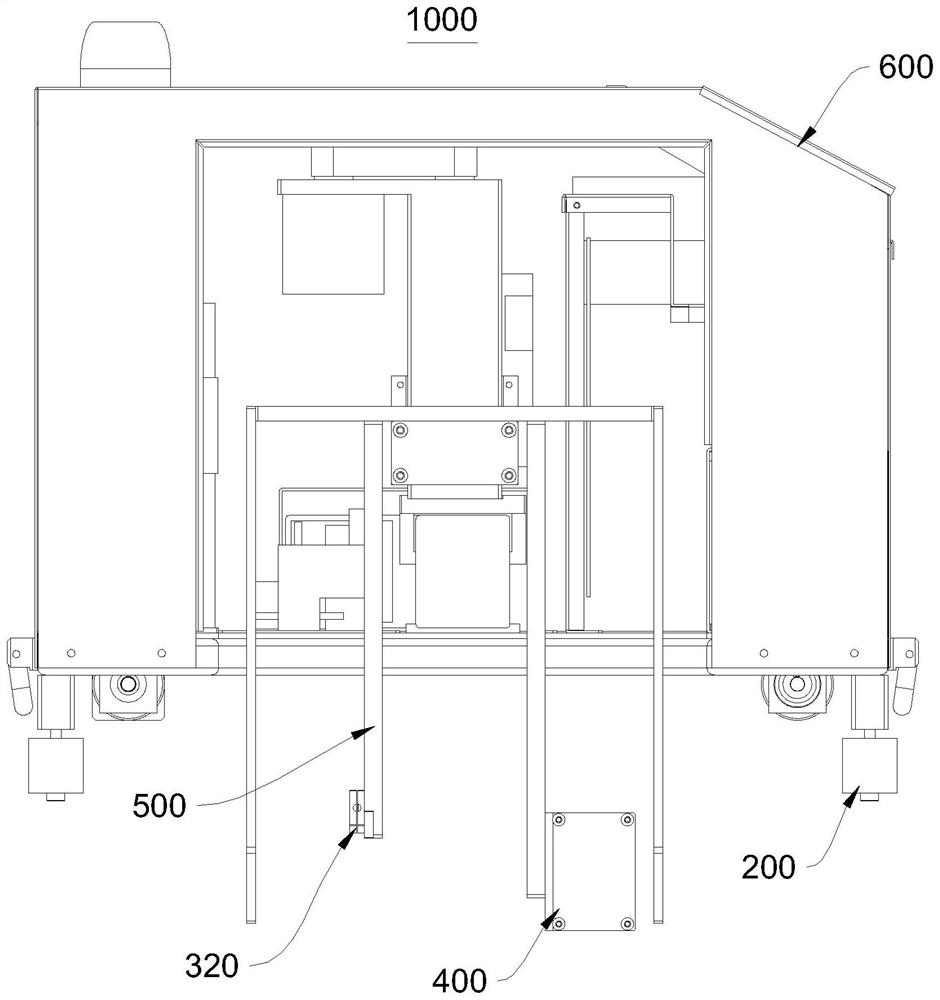

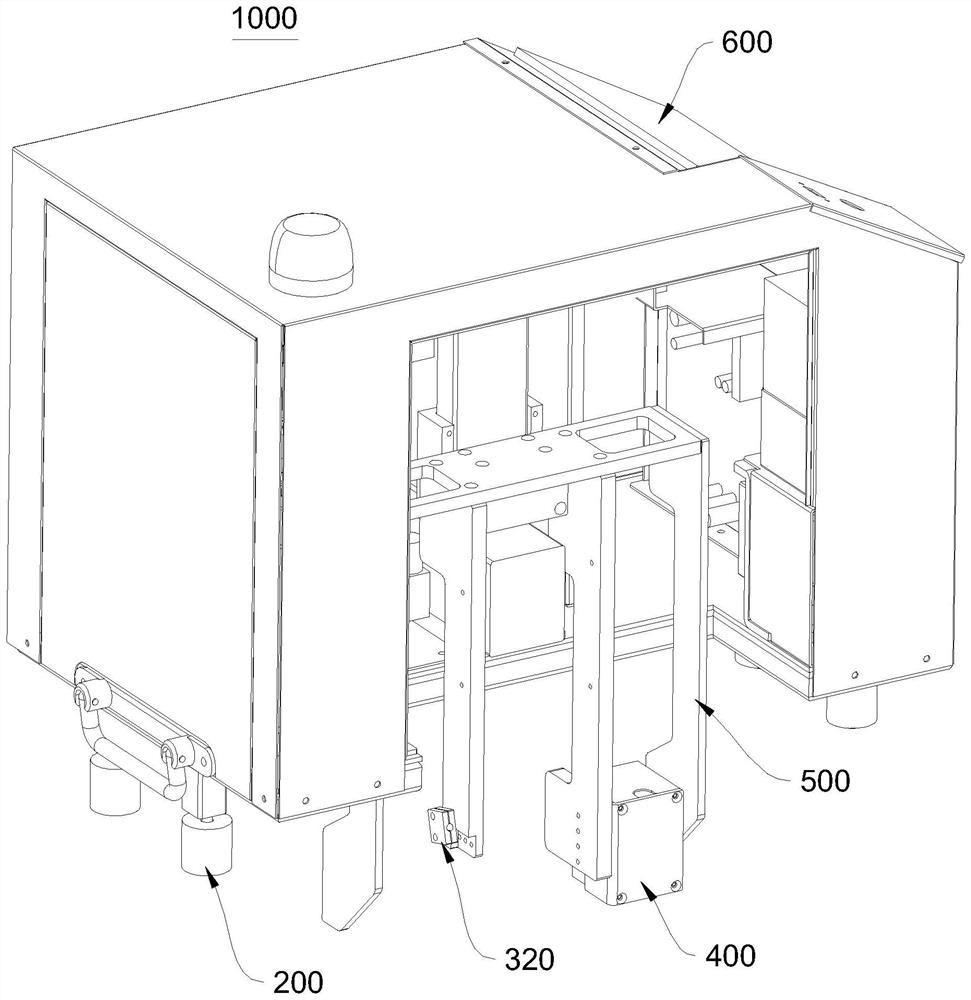

[0043] Please refer to Figure 1 to Figure 4 , This embodiment provides a new type of rail waist inkjet printer 1000 , the new rail waist inkjet printer 1000 includes: a base 100 , a traveling assembly 200 , a painting assembly 300 , a coding assembly 400 , a position adjustment assembly 500 and a control assembly 600 .

[0044] The traveling assembly 200 is installed on the bottom of the base 100 , and the traveling assembly 200 is used to cooperate with the single-side rail, so that the new rail waist inkjet printer 1000 can move along the track.

[0045] Both the paint spraying assembly 300 and the coding assembly 400 are installed on the position adjusting assembly 500 , and the position adjusting assembly 500 is installed on the base 100 and is disposed close to the edge of the base 100 . The position adjustment assembly 500 has a first adjustment direction and a second adjustment direction, wherein the first adjustment direction is set along the height direction of the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com