Cable shear component processing device

A processing device and cable cutter technology, which is applied in the field of cable cutters, can solve the problem that the special cutting edge cannot be processed accurately, and achieve the effect of uniform cutting edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

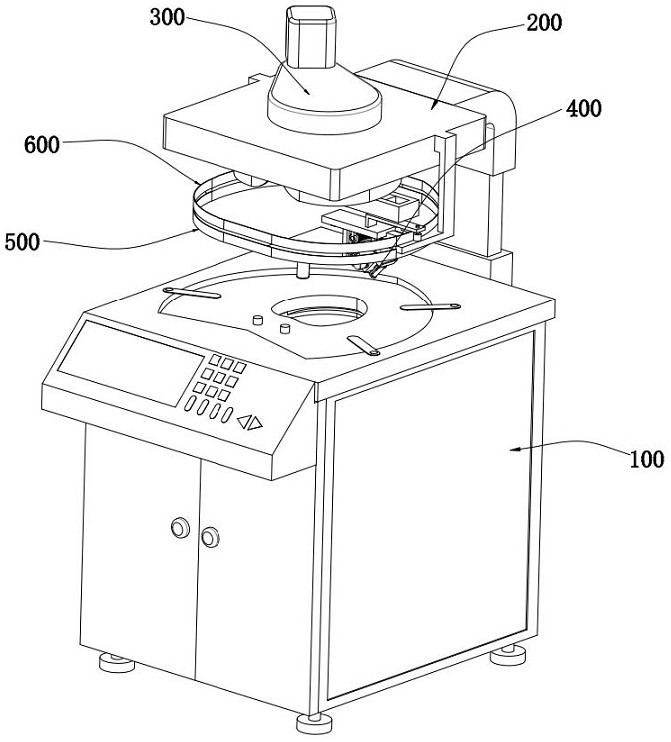

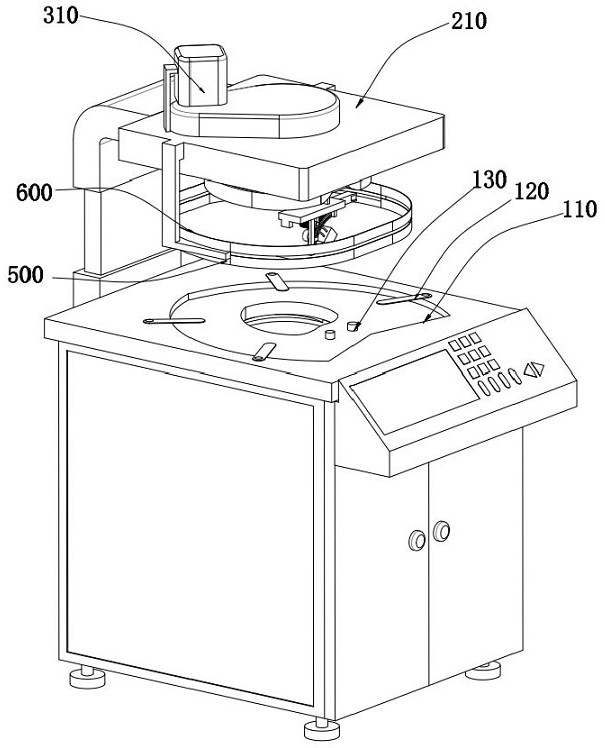

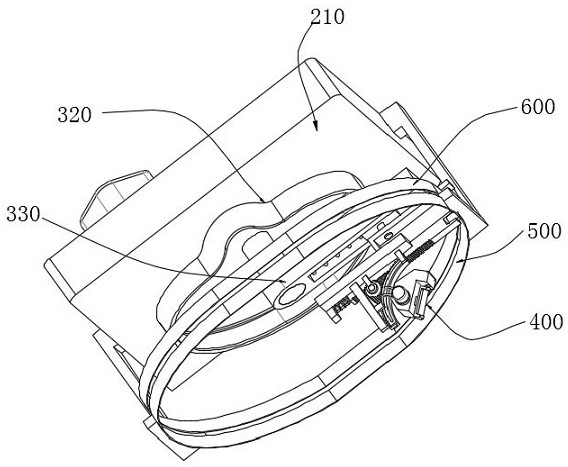

[0041] refer to Figure 1-Figure 14 As shown, in this embodiment, a cable shear member processing device is proposed, including a workbench 100 and a clamp 120, the upper table surface of the workbench 100 is horizontally arranged, the clamp 120 is installed on the workbench 100, and the clamp 120 clamps two The cable shearing member 700 is placed on the upper table surface of the workbench 100. The two cable shearing members 700 are placed horizontally on the upper table surface of the workbench 100. The area enclosed between 710 is a heart-shaped structure;

[0042] The processing device further includes a grinding roller 400, a lifting mechanism 200, a driving mechanism 300, an adjusting mechanism 500 and a limiting mechanism 600. The grinding roller 400 is arranged above the worktable 100 and corresponds to the position of the cable shearing member 700, and the grinding roller 400 is inclined. The lifting mechanism 200 is used to adjust the lifting and lowering of the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com