Food slicer

A slicing machine and food technology, applied in food science, mechanical equipment, metal processing, etc., can solve the problems of knife cutting, high rotation speed, meat scraps contaminating the machine, etc., and achieve the effect of simple debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0236] "Front", "rear", "left", and "right" in this application are subject to the marks in the corresponding drawings.

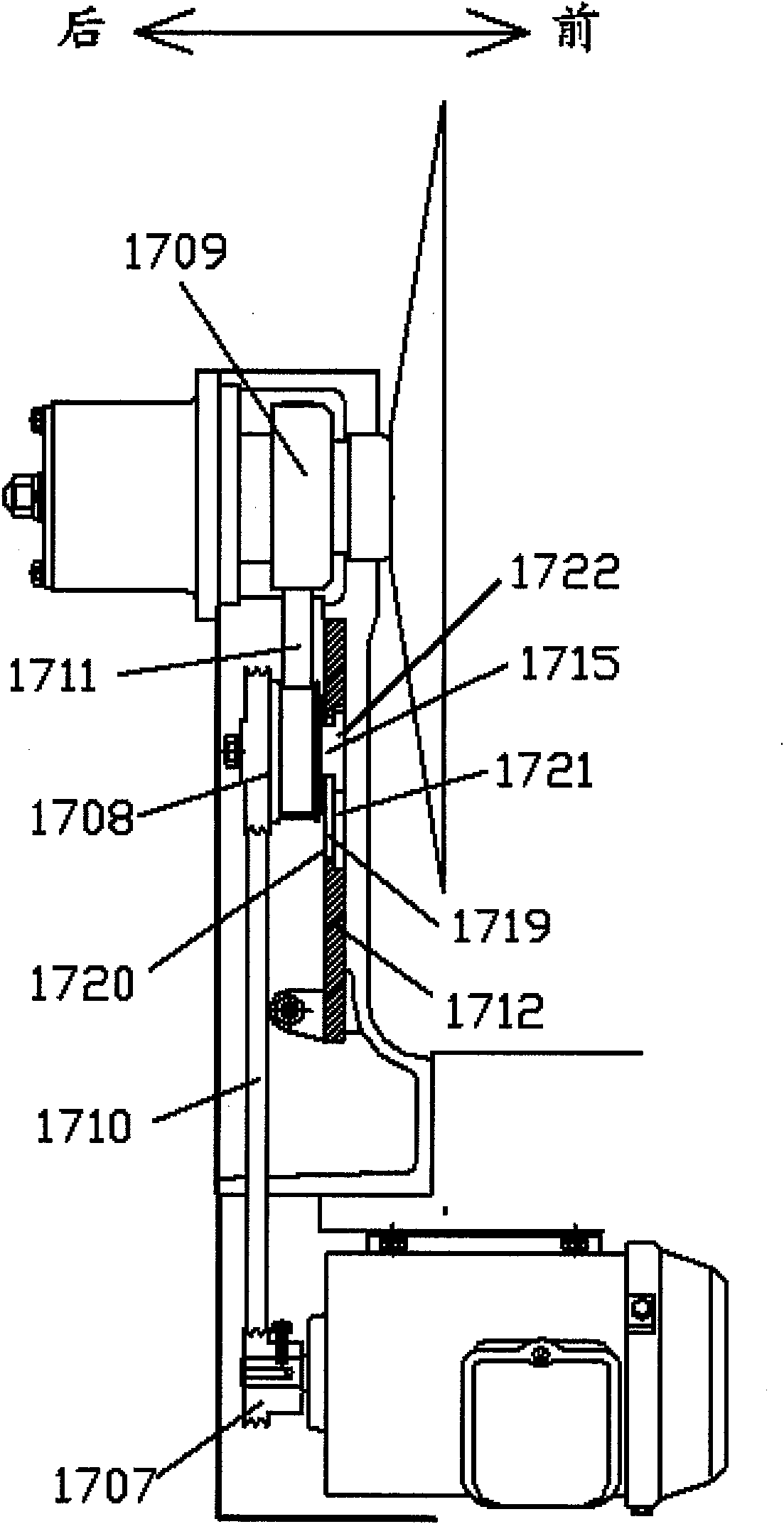

[0237] The following combination Figure 56 A brief description will be given of the food slicer to which the present invention is applied.

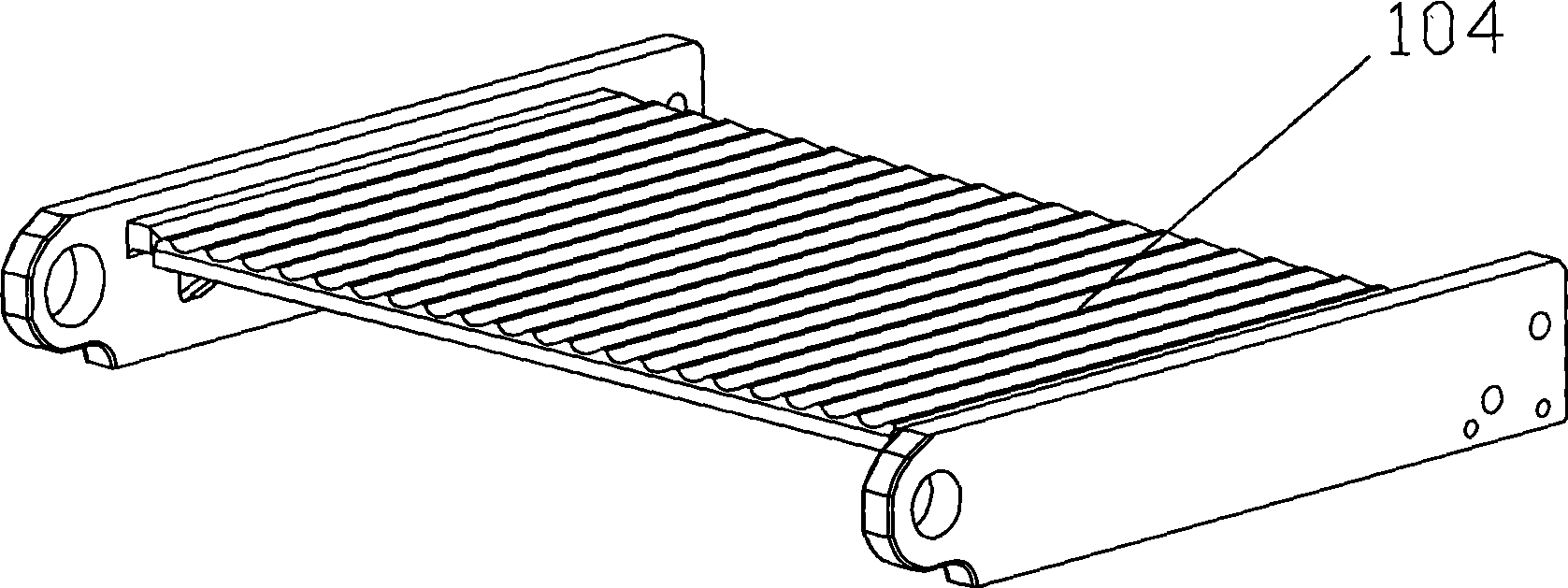

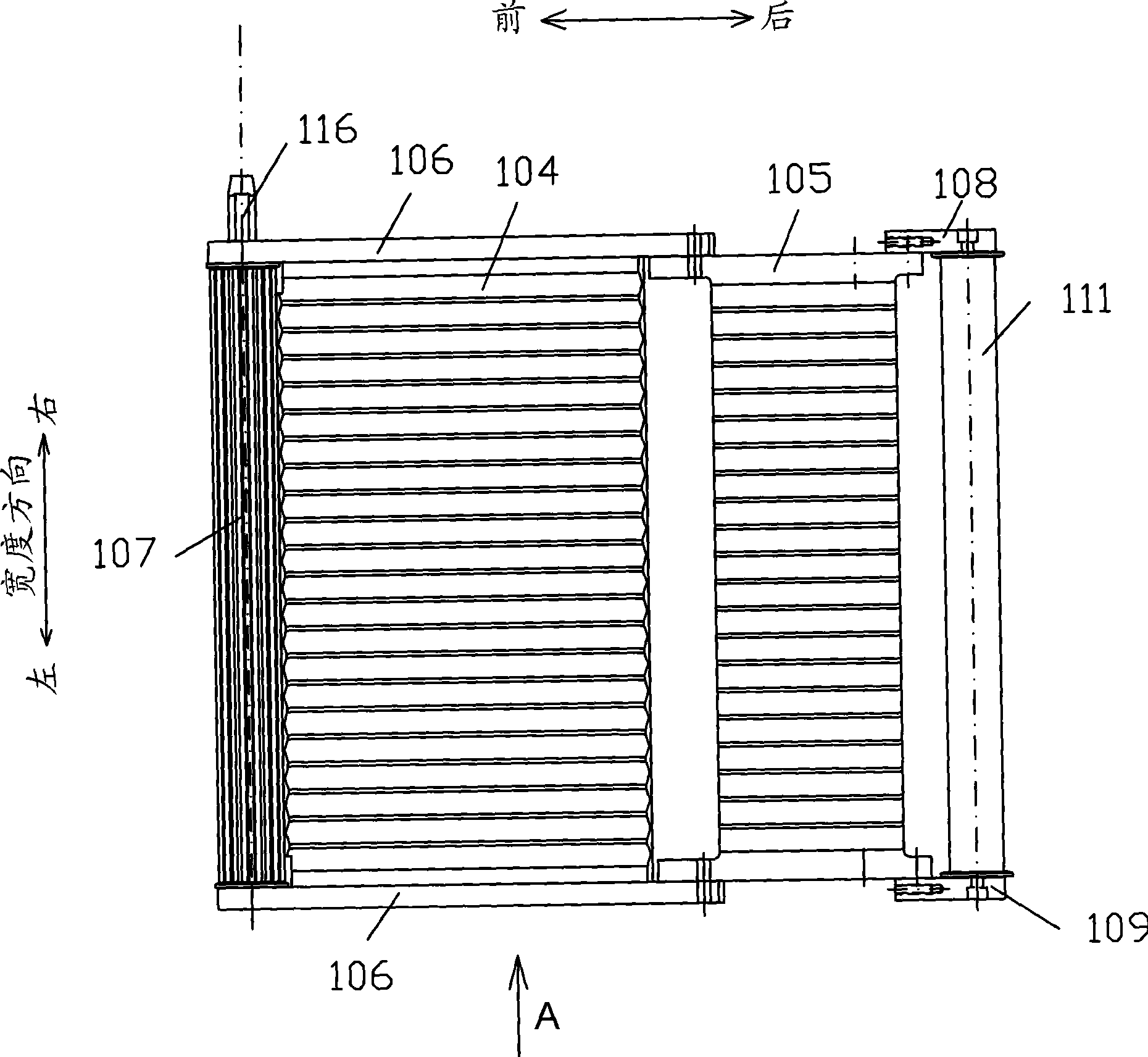

[0238] the above Figure 56 The food slicer shown in the example mainly includes an upper frame device, an upper frame device lifting booster mechanism, a middle frame device, a base platform, a slicing raw material feeding mechanism, a fast slicing raw material feeding mechanism, a cutter device, a driving device, Material box stop position adjustment mechanism, knife sharpening device. The upper frame device is used to press the sliced raw material on the conveyor belt of the middle frame device, so that the sliced raw material does not slide or float on the conveyor belt relative to the conveyor belt, and also plays the role of auxiliary conveying of the sliced raw material. The above-mentioned mid-frame d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com