Ventilator wind power control test tool platform and use method

A technology for testing tooling and wind control, which is applied in the testing of machines/structural components, measuring devices, wind power generation, etc., and can solve problems affecting the ventilation effect and differences of ventilators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

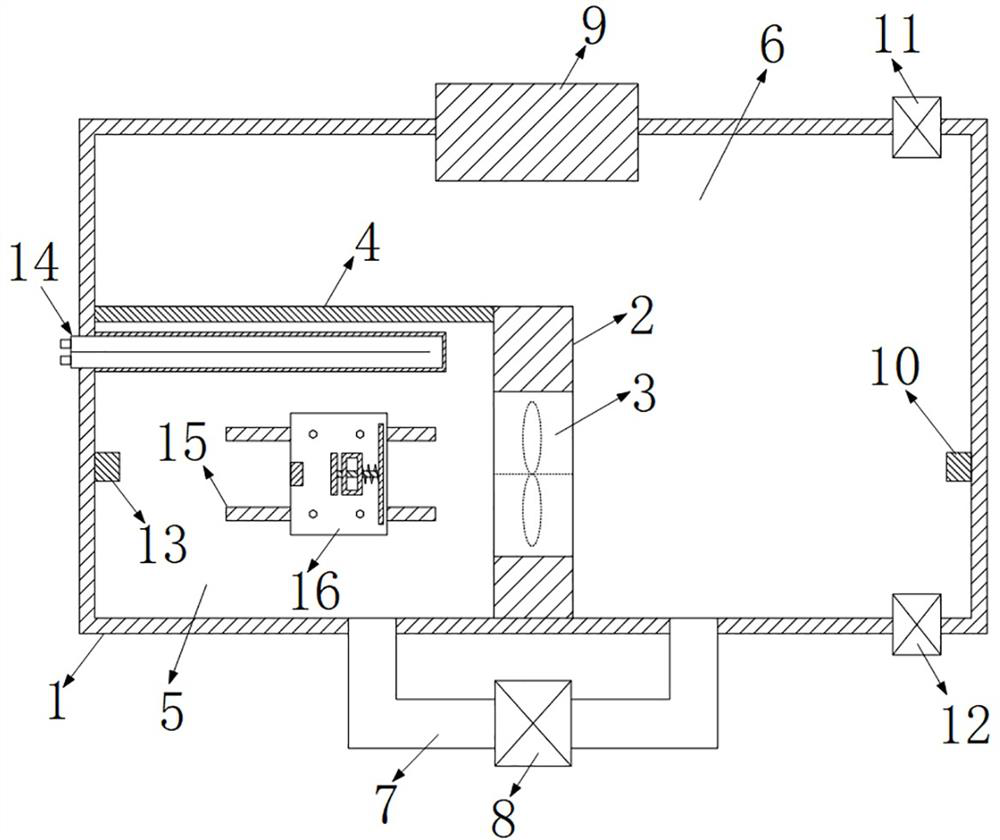

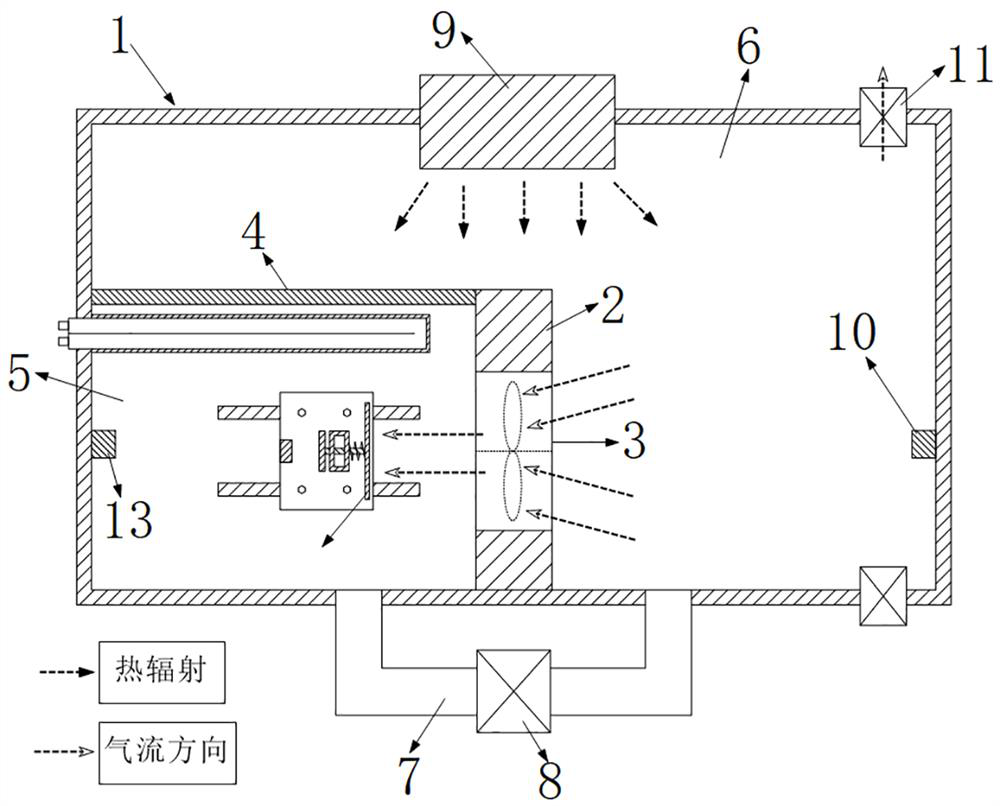

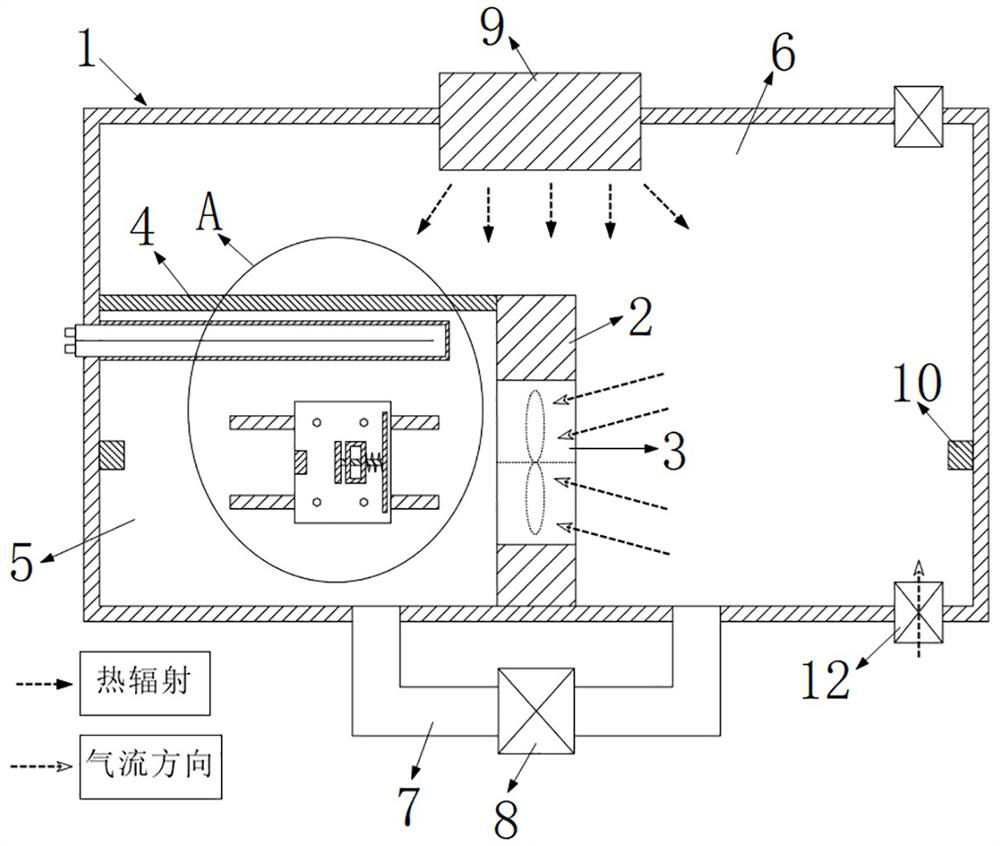

[0024] see Figure 1 to Figure 5 , the main structural features of the ventilator wind control test tooling platform in the present invention are as follows:

[0025] Sealed cabin 1: The fan installation baffle 2 and the heat-absorbing baffle 4 are set inside, thereby forming an inner simulation cavity 5 and an outer simulation cavity 6. The sealing cabin 1 has an integral structure around it, and a removable or flip cover can be set on the upper side. Sealing strips are arranged at the positions where the cover plate and the lower vertical plate (for example, the heat absorption baffle 4 and the fan installation baffle 2 ) are connected.

[0026] Fan installation partition 2: The fan 3 is installed at the position of the fan installation partition 2, and the fan installation partition 2 is provided with an installation position for installing the fan 3.

[0027] Heat-absorbing partition 4: The heat-absorbing partition 4 is made of an alloy material with good thermal conducti...

Embodiment 2

[0044] The present invention relates to a method of using a fan wind control test tooling platform, and the specific contents are as follows:

[0045] The first step is to install the fan 3 to be tested, and the fan 3 is installed at the position of the fan installation partition 2. After the entire sealed cabin 1 is installed, the system starts to activate the heating module 9, and at the same time, the proportional valve 8 of the ventilation connecting pipe 7 is closed. The external temperature sensing module 10 monitors the ambient temperature in the external simulated cavity 6 in real time, and the internal temperature sensing module 13 detects the ambient temperature in the internal simulated cavity 5 in real time.

[0046] In the second step, the heating module 9 heats the heat-absorbing baffle 4, and the thermal radiation energy absorbed by the heat-absorbing baffle 4 is quickly transferred to the inner simulation cavity 5, and at the same time, the temperature-adjustin...

Embodiment 3

[0052] In the present invention, to maintain the correlation mapping relationship between the temperature of the inner simulation cavity 5 and the temperature of the outer simulation cavity 6, the guide rail 15, the base plate 16, the test components, etc. can be placed in the outer simulation cavity 6, and the air outlet side of the fan 3 can be placed in the outer simulation cavity 6. In the external simulation cavity 6, the ventilator 3 blows air toward the external simulation cavity 6, and the air flow blowing effect of the ventilator 3 from the workshop environment to the outside world is tested. Airflow effects are fully tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com