Outdoor prefabricated substation

A prefabricated substation, outdoor technology, applied in the field of substations, can solve the problems of easy occurrence of waterlogging, easy to be affected by outdoor environment, affecting the safety of electrical appliances in prefabricated cabins, etc., to achieve the effect of improving the protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

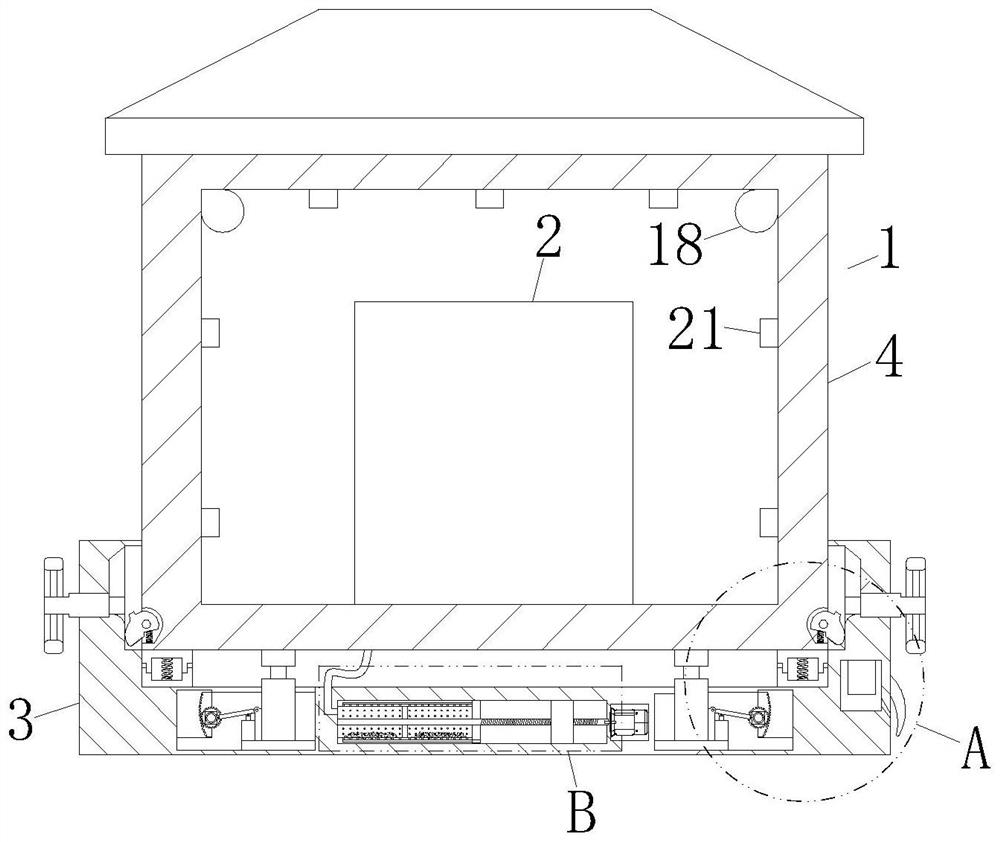

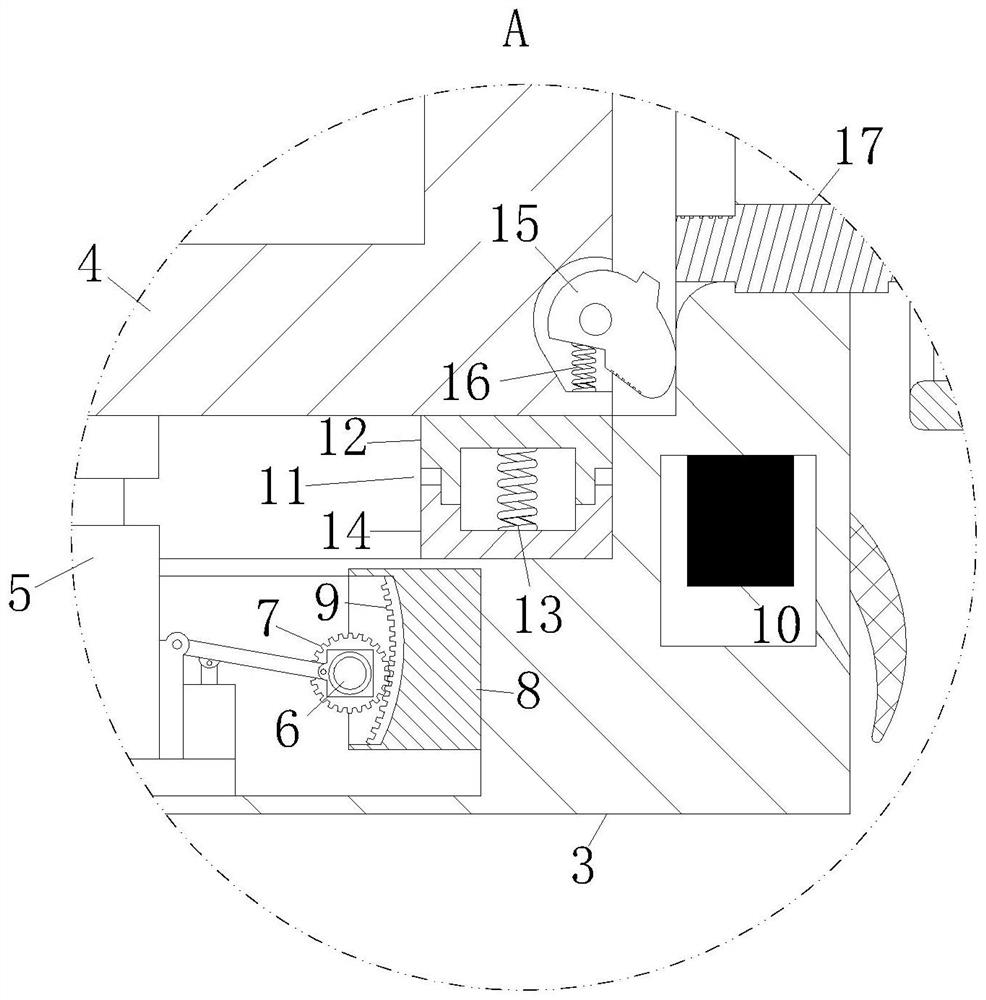

[0029] like Figure 1-Figure 3As shown, an outdoor prefabricated substation according to an embodiment of the present invention includes a prefabricated cabin 1 and a built-in transformer equipment 2; the interior of the prefabricated cabin 1 is provided with a built-in transformer equipment 2; the prefabricated cabin The body 1 includes a base 3 and an upper cabin 4; the top surface of the base 3 is provided with a chute; the interior of the chute is slidably connected with the upper cabin 4; the interior of the base 3 is provided with a jack 5; The surface of the lifting handle of the jack 5 is fixedly connected with the first motor 6; the surface of the lifting handle of the jack 5 is rotatably connected with a gear 7, and the gear 7 and the output shaft of the first motor 6 are fixedly connected; A guide block 8 is fixedly connected inside; a side surface of the guide block 8 relative to the gear 7 is provided with a mounting groove; the interior of the mounting groove is ...

Embodiment 2

[0038] like Figure 5 As shown in the comparison example 1, another embodiment of the present invention is: the inside of the swivel ring 27 is provided with evenly arranged guide holes 29; the inner surface of the swivel ring 27 is provided with evenly arranged through holes 30; During operation, by opening the guide hole 29 and the through hole 30 inside the swivel ring 27, and through the movement of the pressure control block 24, the squeezing gas is directly introduced into the inside of the guide hole 29, and then the gas will enter the through hole through the guide hole 29. Inside the hole 30 , gas is injected into the inside of the swivel ring 27 through the through hole 30 , so as to improve the mixing effect of the dry powder 20 inside the swivel ring 27 .

[0039] The position of the connecting hole 28 is close to the bottom position of the partition plate 25; during operation, by opening the connecting hole 28 at the bottom position close to the partition plate 25...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap