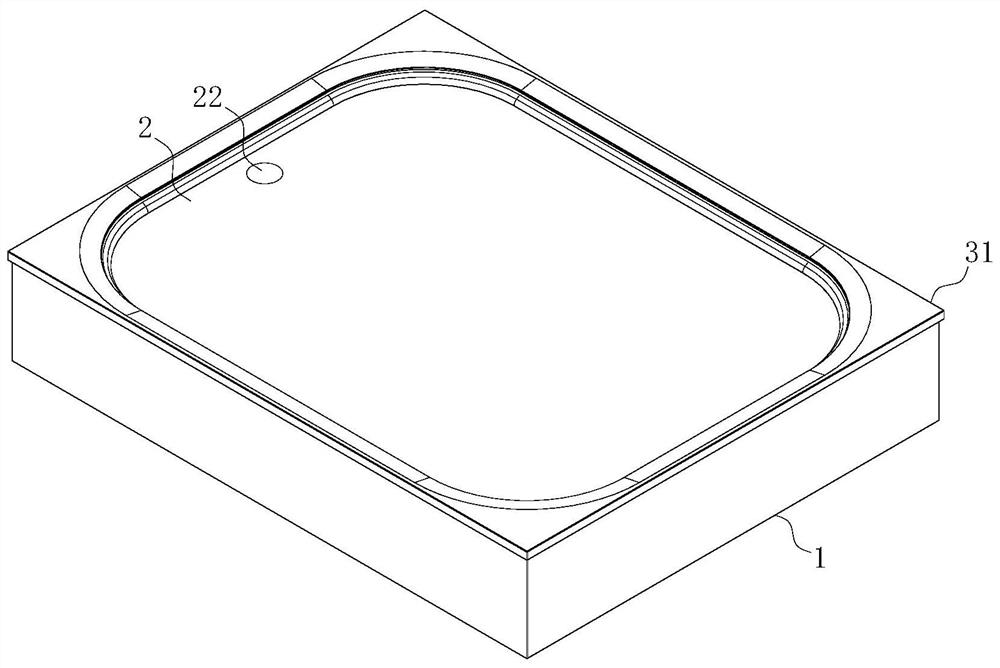

Split type shower bottom basin

A split type, bottom basin technology, applied in showers, bathtubs, home appliances, etc., can solve the problems that maintenance personnel cannot perform maintenance, can no longer make effective adjustments, and have high technical requirements for installation, so as to avoid hard contact and facilitate maintenance. , the effect of reducing technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

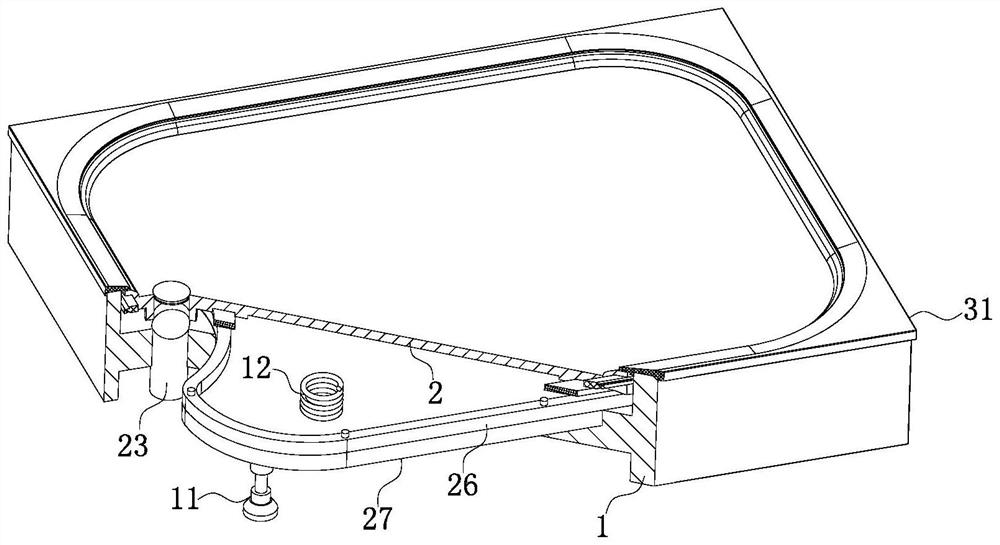

Embodiment approach

[0026] As an embodiment of the present invention, the lower surface of the movable plate 2 is provided with a limit groove 24, and the limit groove 24 is designed as an arc-shaped avoidance structure at the position of the drainage hole 22 to avoid interference; The inside of the groove 24 is equipped with a buffer pad 25; the position directly below the spacer 24 is provided with a spacer 26 of the same shape; during work, when the shower personnel stood on the upper surface of the movable plate 2, the The bottom is only supported by the spring 12. If the shower personnel are heavier, they will exert greater pressure on the spring 12, which will cause serious damage to the effective rebound of the spring 12 after long-term use. If the shower personnel are lighter, the spring 12 will The amount of compression deformation is small, so the movable plate 2 is easy to shake up and down, resulting in a potential risk of use. In order to solve this problem, by setting the limit jack ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap