Method for producing row of artificial eyelashes

A technology of artificial eyelashes and false eyelashes, which is applied to hat products, clothing, hair accessories, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

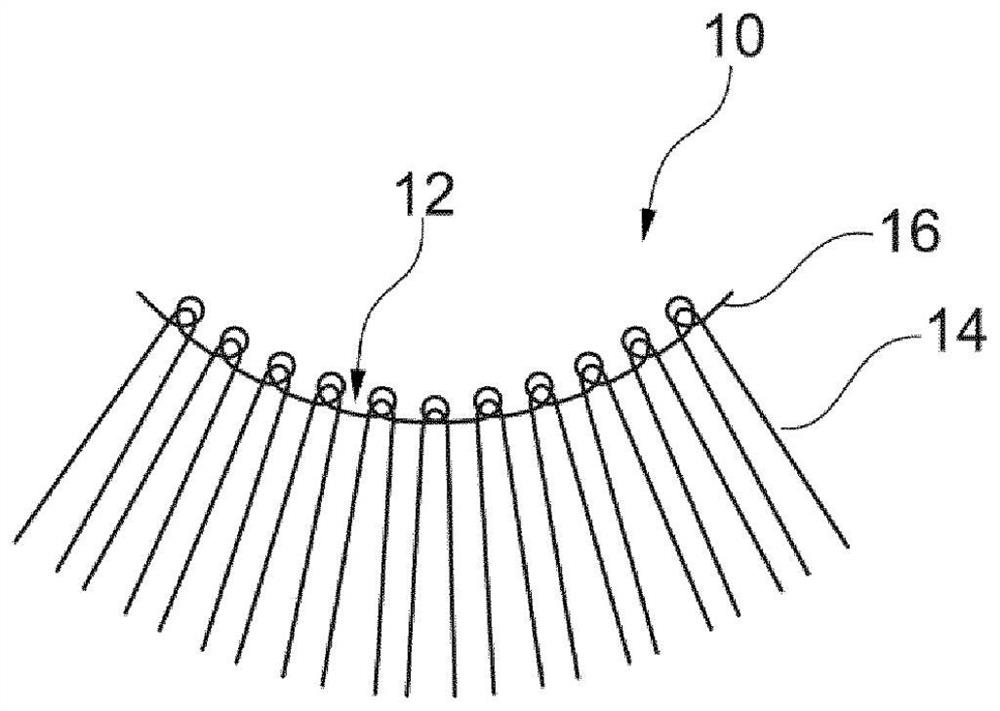

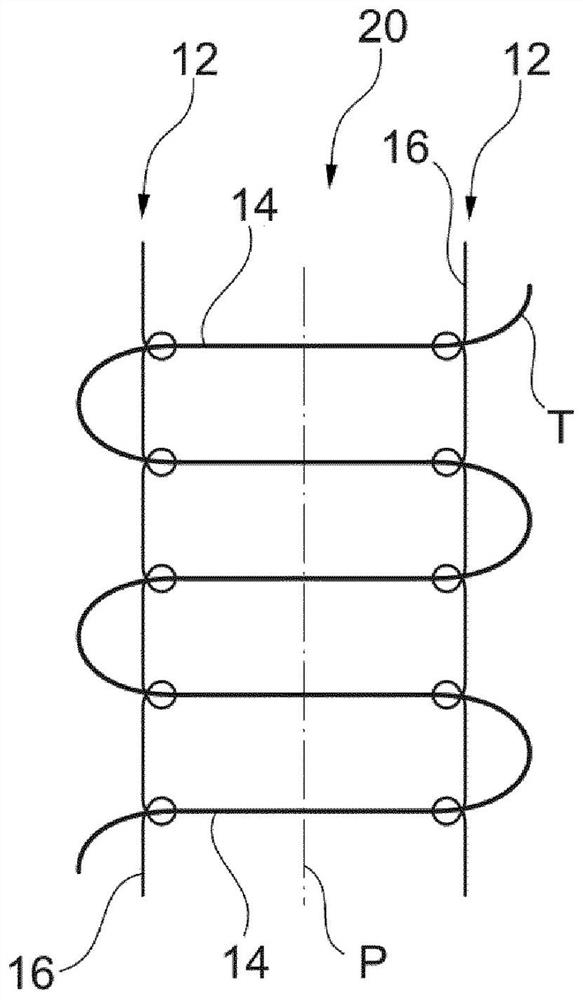

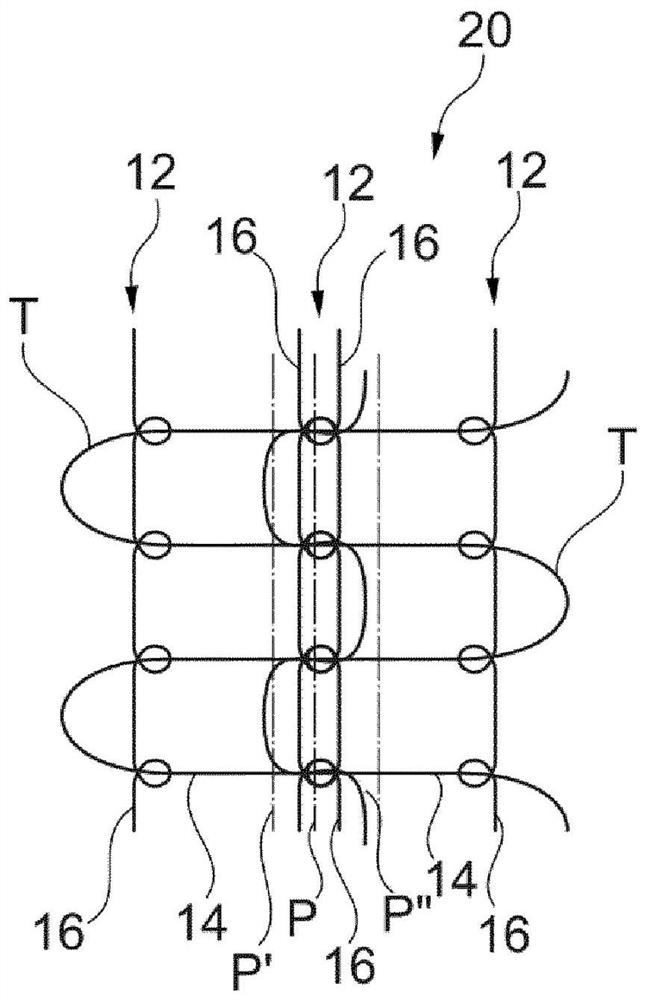

[0195] In one embodiment of the invention, the method is carried out by the following sequential steps:

[0196] (a) Weaving an assembly for forming multiple rows of artificial eyelashes to be secured to the lid margin, the assembly having at least two bases and false eyelashes, at least one base for securing to the lid margin, the bases being mutually relative to the midplane Arranged in parallel and symmetrically, each base has a first warp thread forming a stitch, in particular a chain stitch braided warp thread.

[0197] (e) Activating the heat-fusible warp thread or strands to secure the sutures of the base. Activation may include heating, especially for example by baking or heating rollers or steam. Next, clean the components.

[0198] (b) bending a row of artificial eyelashes and / or base and / or false eyelashes by applying a mechanical load in the presence of an energy stimulus that causes the false eyelash material to heat up, in particular by applying ultrasound or h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com