Flexible artificial eyelashes manufactured by injection molding process

An artificial technology for eyelashes, applied in hats, clothing, bald wigs, etc., can solve the problems of increasing the manufacturing cost of eyelash crafts, high waste rate of eyelash crafts, and uneven products, so as to improve its own image and yield The effect of high height and many styles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

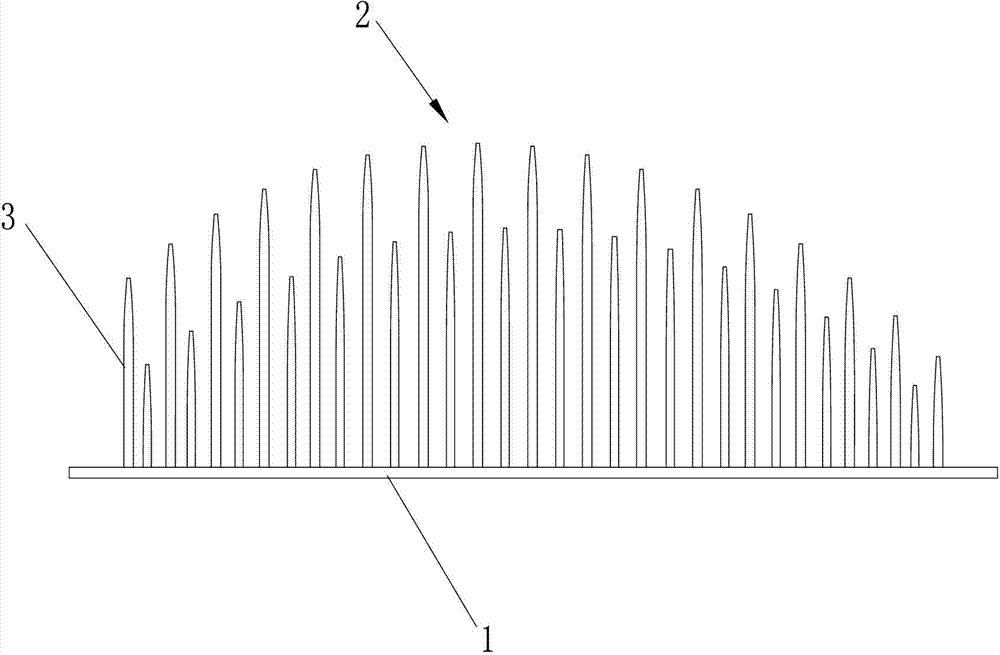

[0032] Embodiment 1: see attached figure 1 And attached Figure 16 As shown, the flexible artificial eyelashes produced by the injection molding process described in this embodiment include an artificial eyelash unit formed by integral injection molding of the bonding part 1 and the eyelash part 2, and the eyelash part 2 is mainly composed of a plurality of eyelashes. 3, and the plurality of eyelashes 3 are arranged along the shape track of the bonding part 1, wherein the bonding part 1 is injection molded into an elastic linear shape according to the curve of the eyelid of a person. The cross-sections of the bonding part 1 and the eyelashes 3 are circular, elliptical, regular or irregular polygons (such as square, rectangle, triangle, parallelogram, pentagon, trapezoid, etc.).

Embodiment 2

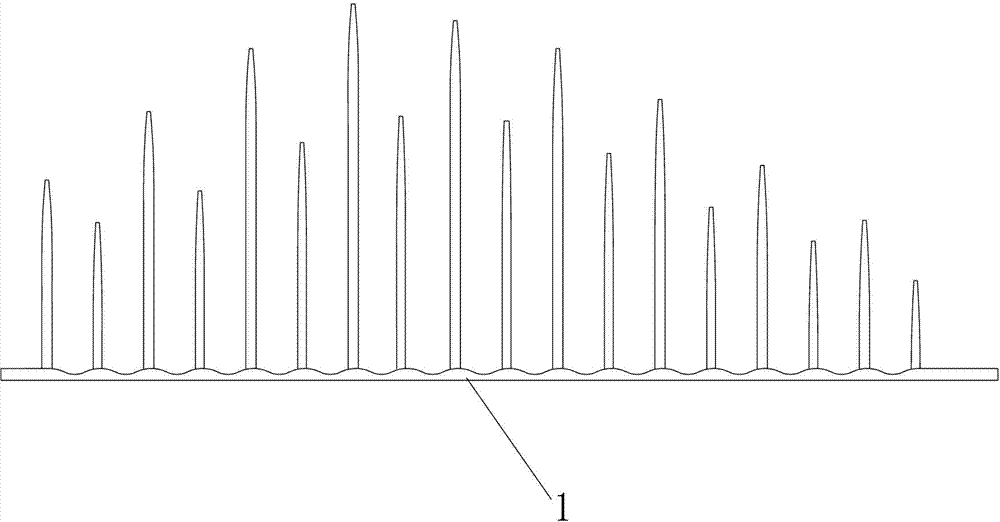

[0033] Embodiment 2: see attached figure 2 As shown, the difference from Embodiment 1 is that the surface of the body of the elastic linear bonding part 1 described in this embodiment is formed with a waveform, and the waveform can be a sine wave, a triangular wave, a square wave, a trapezoidal wave, a special-shaped wave or one of them. At the same time, the crest and bottom of the wave form and the respective two sides can be arc transitioned, the specific situation is determined according to the customer's requirements, and the wave form is formed on the front end of the bonding part 1.

Embodiment 3

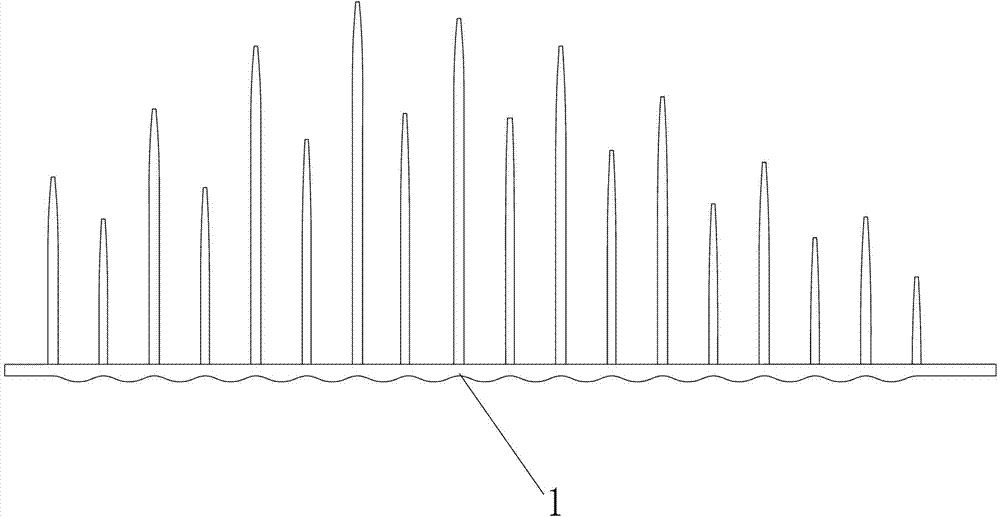

[0034] Embodiment 3: see attached image 3 As shown, the difference from Embodiment 2 is that the waveform described in this embodiment is formed at the rear end of the bonding portion 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com