Anti-disassembly bounce-off type beacon locking and releasing device

A locking-release and pop-up technology, applied in the direction of fixtures, machines/brackets, supporting machines, etc., can solve the problems of low locking and releasing reliability, false triggering and false releasing of beacons, complicated structure, etc., to avoid Electronic interference, improved reliability, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following is further described in detail by specific embodiments:

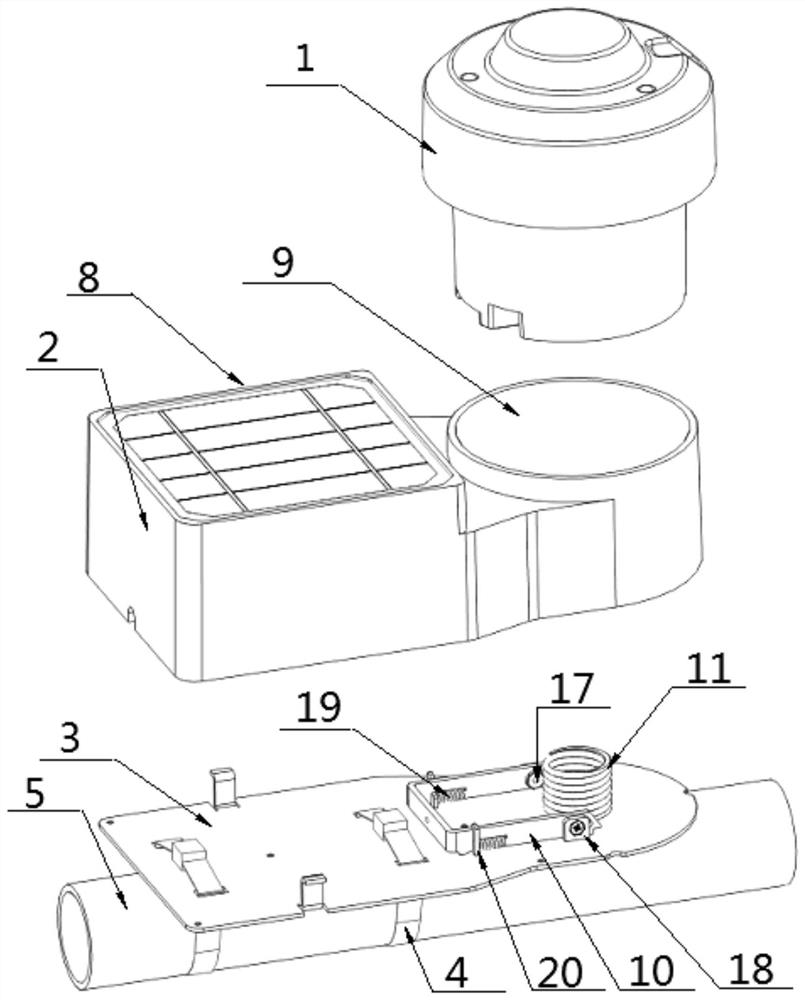

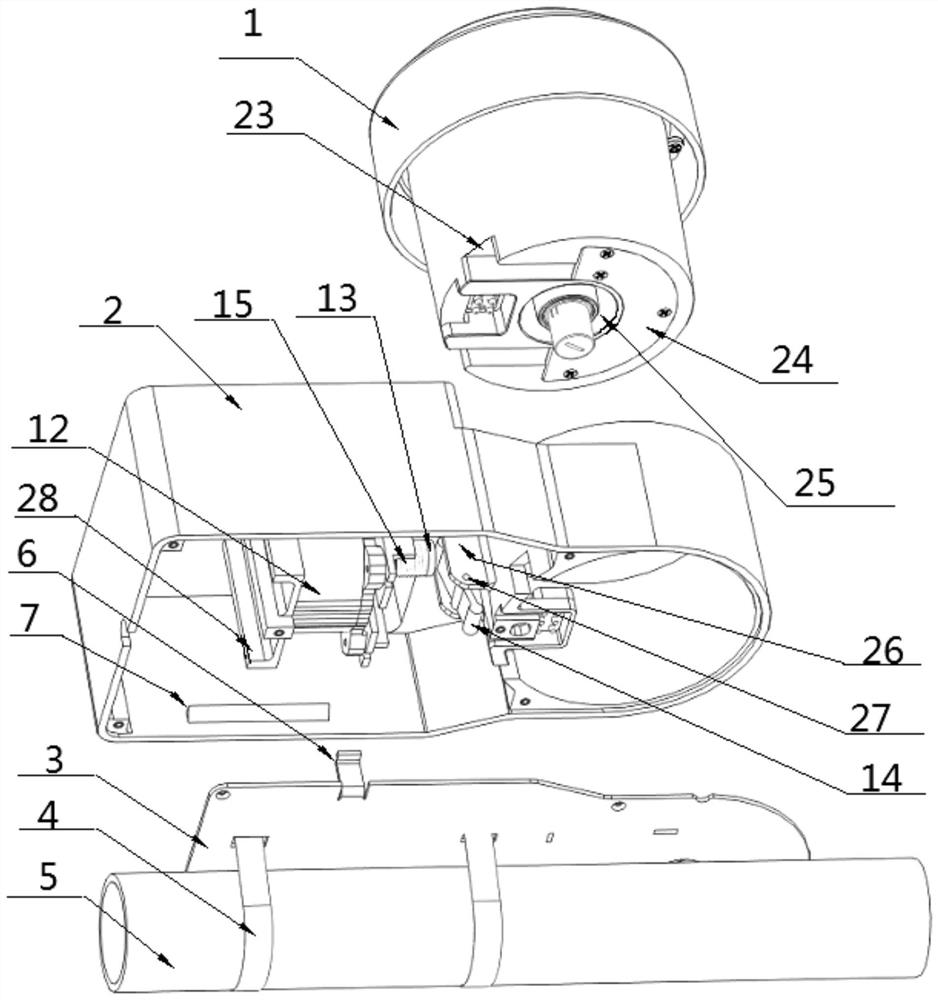

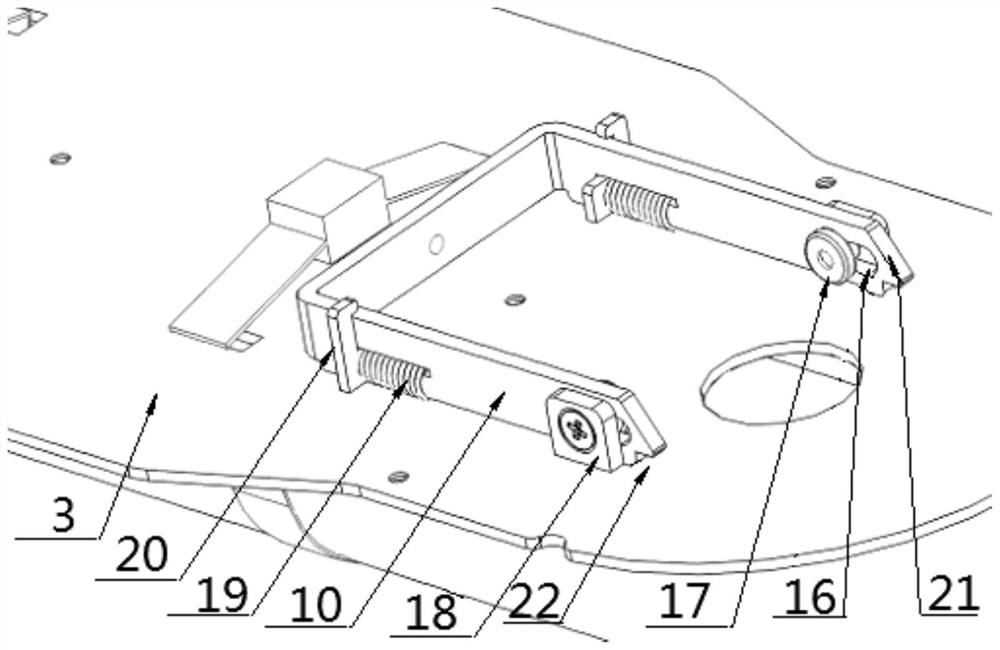

[0043] The reference signs in the drawings include: beacon 1, shell 2, base 3, throat hoop 4, fence 5, barb buckle 6, clamping block 7, solar charging device 8, beacon mounting hole 9, U Type lock tongue 10, beacon spring 11, hydrostatic pressure release 12, push rod 13, lever lever 14, push rod spring 15, limit hole 16, limit pin 17, baffle 18, U-shaped lock Tongue spring 19 , limit plate 20 , inclined surface 21 , cut angle 22 , U-shaped groove 23 , buckle plate 24 , annular groove 25 , support lug 26 , pin shaft 27 , mounting piece 28 .

[0044] The example is basically as attached figure 1Shown: An anti-disassembly pop-open locking and releasing beacon 1 device for locking and releasing the beacon 1, including: a casing 2, a base 3, a throat hoop 4 and a locking and releasing mechanism; the locking and releasing mechanism part Set on the base 3, partly on the inner wall of the shell 2, the she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com