Control method for channeling of hot continuous rolling CVC working roll

A control method and technology of work rolls, which are applied in the field of strip rolling, can solve the problems of affecting the stability of specification jumps, excessive roll shifting strokes, and insufficient roll shifting strokes, so as to prevent excessive shifting and roll with the same width. The effect of increasing the number of rolling kilometers and increasing the number of rolling kilometers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

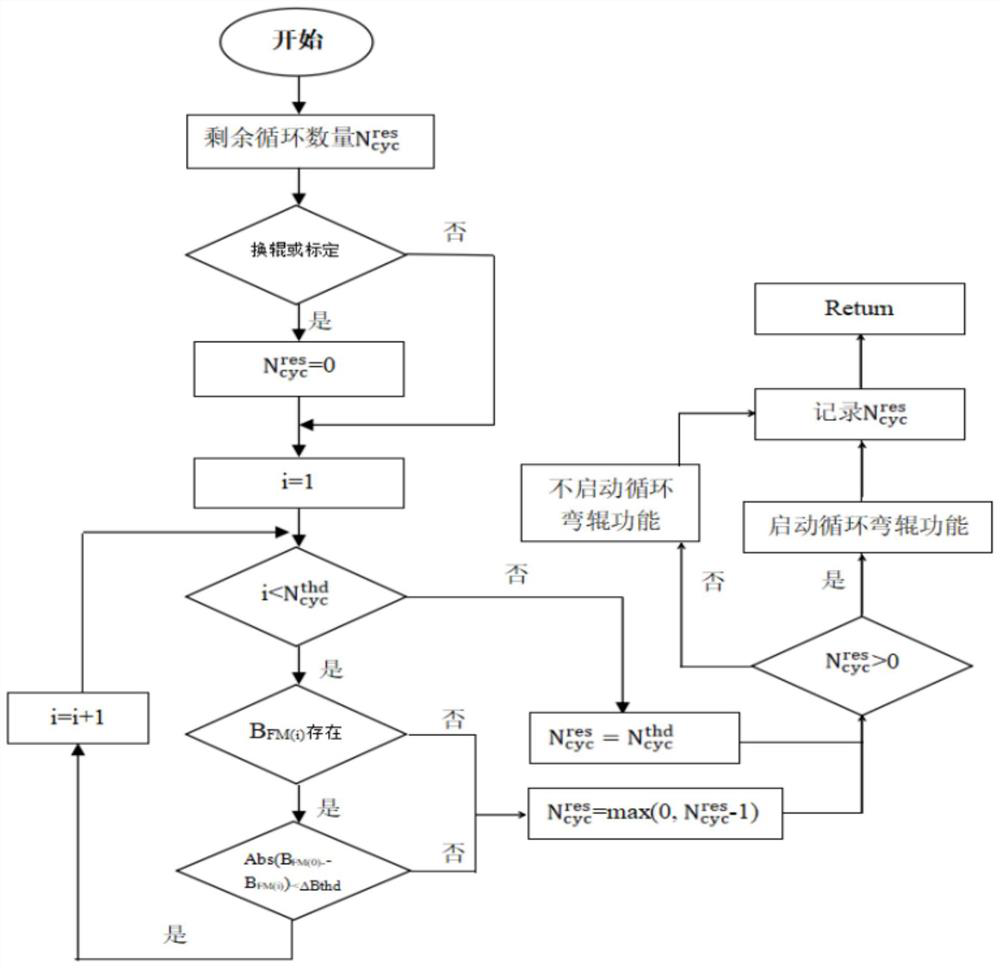

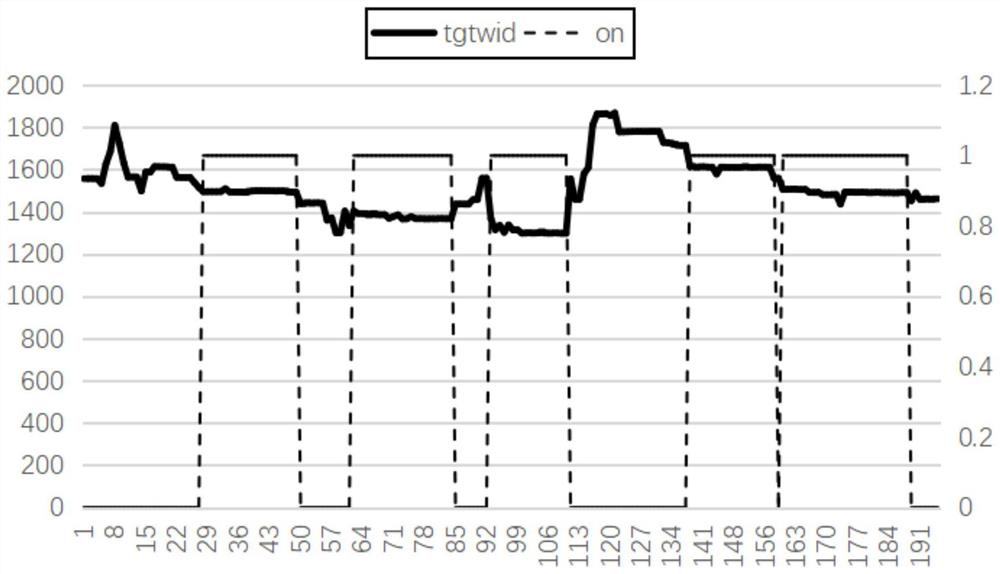

[0037] A method for controlling the shifting of CVC work rolls in hot tandem rolling in this embodiment includes the following steps:

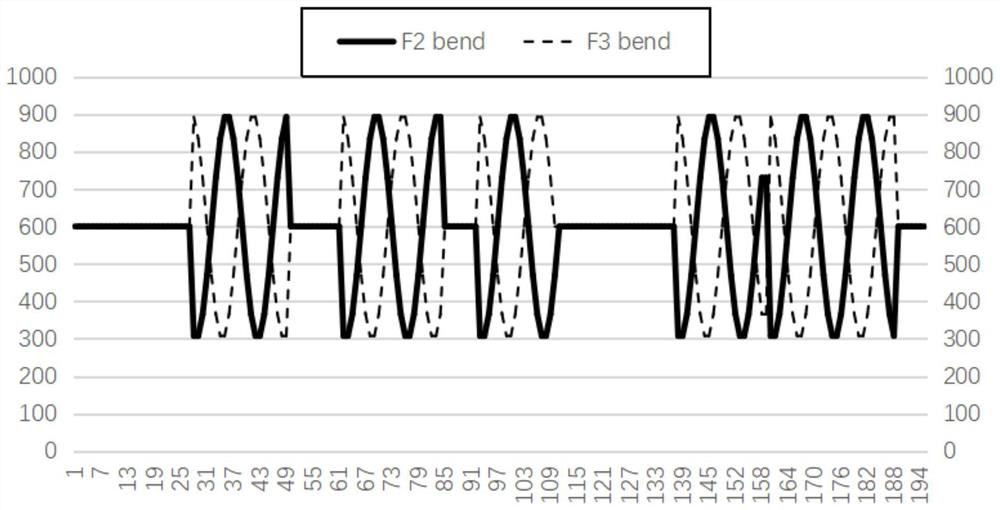

[0038] Step 1: Configure the bending force variation amplitude for each stand of the finishing rolling

[0039] Step 2, configure the preset offset strip number for each stand of finishing rolling

[0040] Step 3, according to the change amplitude of the bending force Number of preset offset strips Change period strip number N cyc , get the bending force change value FB of each framechg ;

[0041] Step 4: Build a model related to the change of roll shifting and the change value of the bending force, and obtain the equivalent roll shifting amount ΔS and the set roll shifting amount S after the roll bending change. norm ;

[0042] Step 5: Determine whether the roller shifting conditions are met. If the conditions are met, the roller shifting is performed according to the model constructed in step 4.

[0043] Among them, the judgment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com