Angle changeable double reflection mirror dynamic liquid film thickness measuring instrument

A double-mirror, liquid film thickness technology, applied in the direction of instruments, measuring devices, grinding machines, etc., can solve problems such as troublesome work, affecting work efficiency and polishing quality, and achieve the goal of improving work efficiency, improving polishing conditions, and ensuring polishing quality Effect

Inactive Publication Date: 2004-04-28

CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method only knows that the thickness of the liquid film has been adjusted. In fact, there is no concept of quantity for the thickness of the liquid film. Every time a workpiece is polished, the counterweight test must be adjusted, which brings trouble to the work and affects work efficiency and polishing. In order to overcome the above shortcomings, a device that can dynamically measure the thickness of liquid film in real time is specially designed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

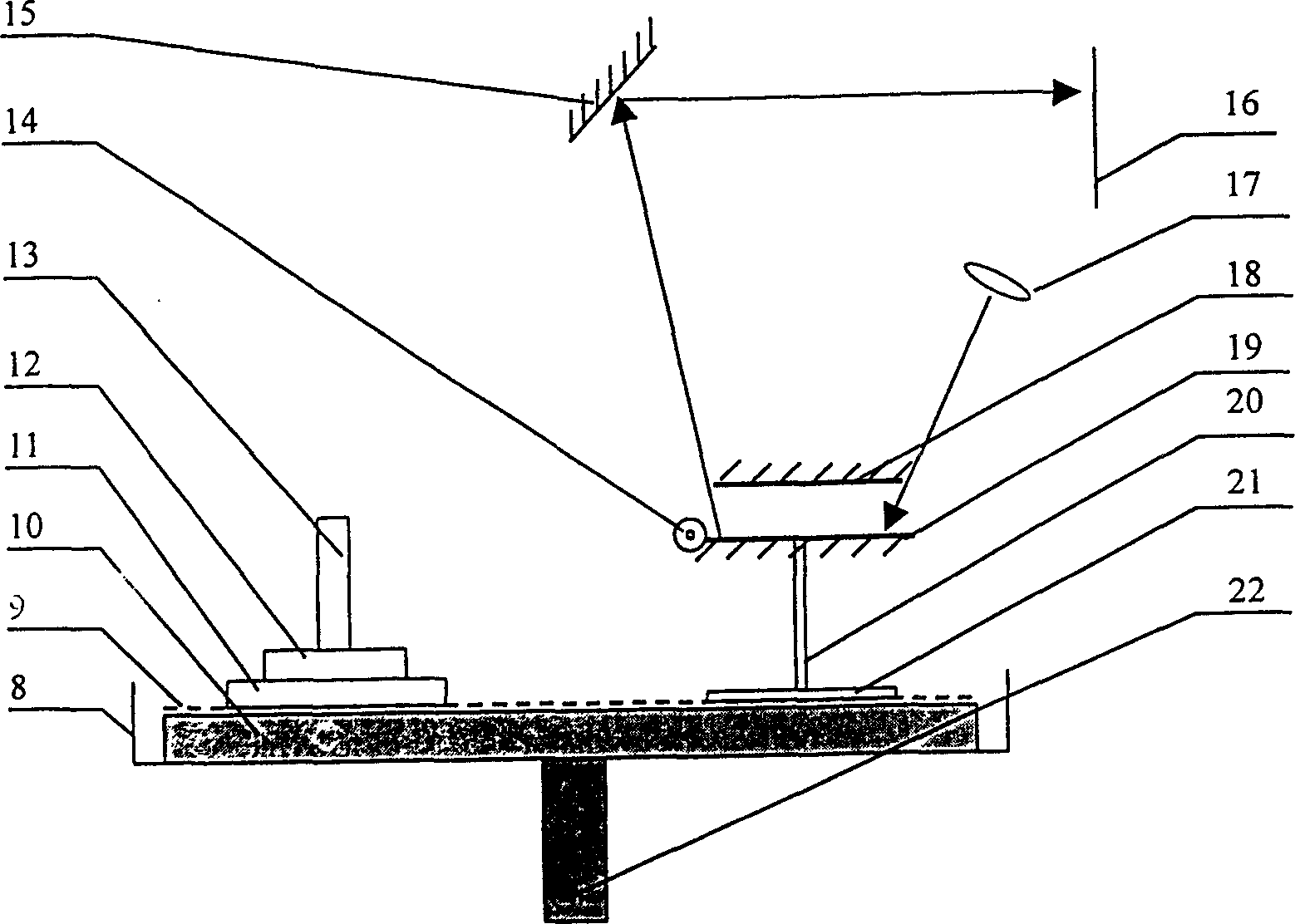

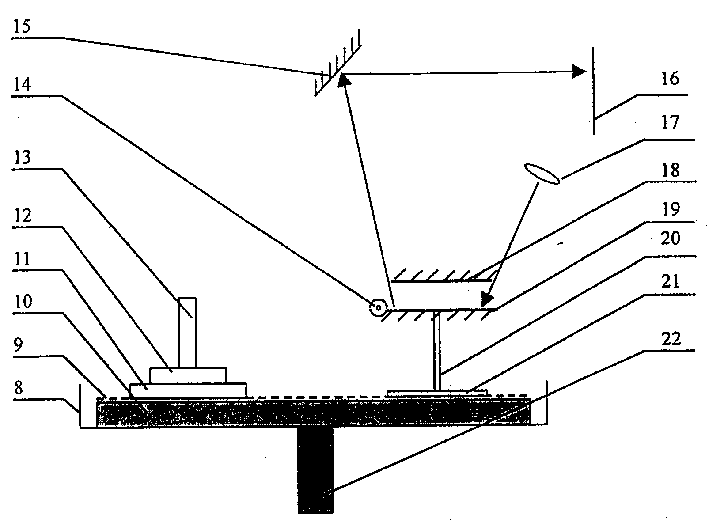

[0014] according to figure 2 The structure shown in the implementation, the reflectivity of the upper and lower reflectors 18 and 19 will be higher than 95%, the rotating shaft 14 adopts a smooth rotating shaft, the sliding seat 21 and the push rod 20 adopt light materials, and the plane reflector 15 adopts an aluminum reflector. The reflectivity is higher than 95%, and the observation screen 16 adopts frosted glass with scales.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to an equipment for measuring thickness of polishing liquid film. Its technical problem required to solve lies in that the change of liquid film thickness can be converted into the change of turning angle of lower reflector relative to upper reflector. The technical scheme of solving said problem lies in that in angle-changeable double-reflector it adopts a structure in which a light sldie carriage is used to upwards support the lower reflector whose top rod support is equipped with smooth rotating shaft and make the lower reflector turn round rotating shaft, and utilizes the angle-changeable double-reflector mounted opposite to reflecting surface to make multiple reflection and emit laser beam, and said laser beam can be received by frosted glass. Said invention contains polishing system and measuring system, and implement reel-time dynamic measurement of liquid film thickness, can promptly regulate liquid film thickness, improve polishing conditon, raise working efficiency and ensure polishing quality.

Description

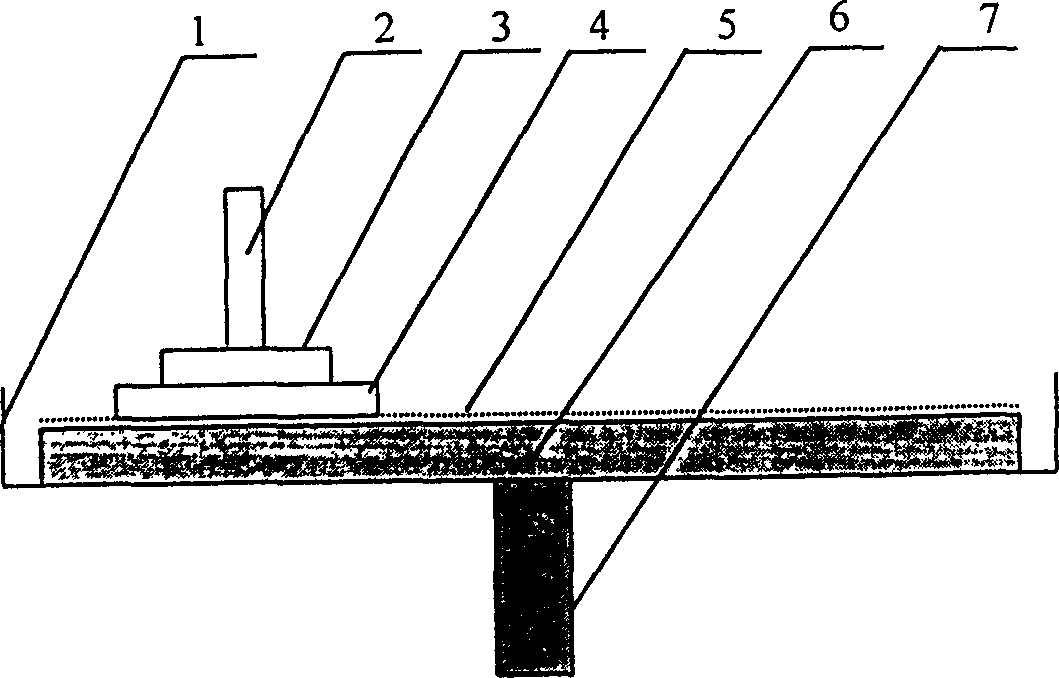

technical field [0001] The invention belongs to a measuring device for polishing liquid film thickness in the technical field of optical cold processing. Background technique [0002] In optical cold processing, it is often encountered that some lenses need to be processed with ultra-smooth surfaces. For example, in short-wavelength optics, the extreme violet lithography system used in the manufacture of VLSI requires the imaging quality of the optical system to be particularly clear. This requires the surface roughness of the optical lens to reach an ultra-smooth level of less than 1nm (RMS). [0003] Generally speaking, for optical cold processing of ultra-smooth surfaces, the usual grinding method of direct contact between the surface of the workpiece and the grinding disc cannot be used, but the grinding solution is used to fill the gap between the surface of the workpiece and the grinding disc. The relative movement of the workpiece forms the solution flow in the gap s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B24B13/00G01B11/06

Inventor 王君林徐长山

Owner CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com