Device and method for thermal conditioning of preforms

A technology for preformed parts and heat regulation, which is applied in the direction of household components, household appliances, and other household appliances, etc., and can solve problems such as filter blockage, blower loss of efficiency, and rated air flow rate not meeting the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

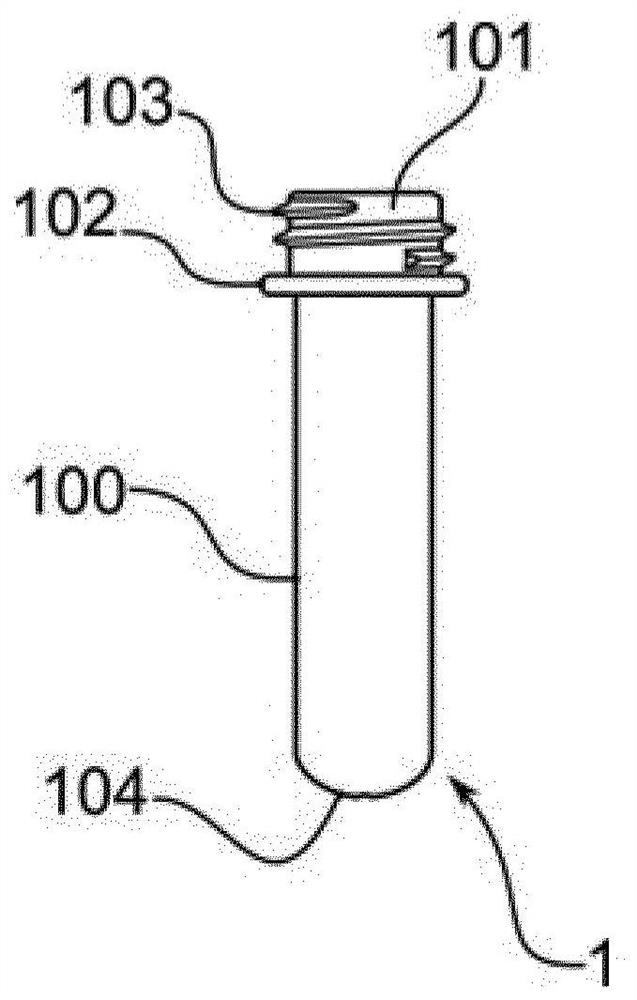

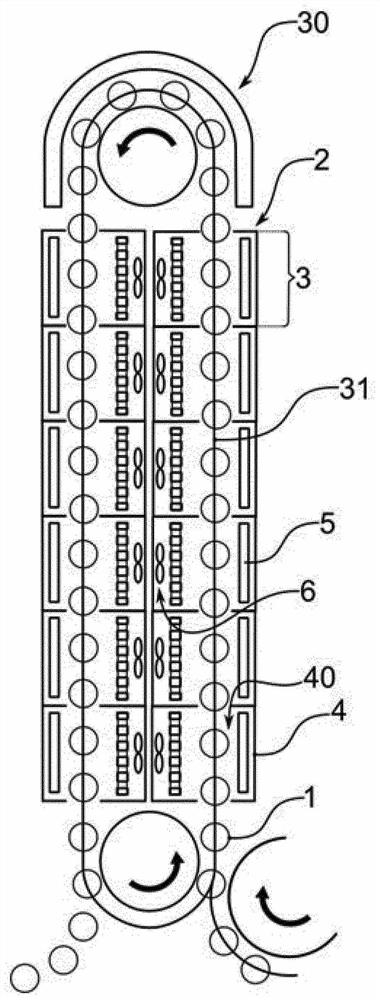

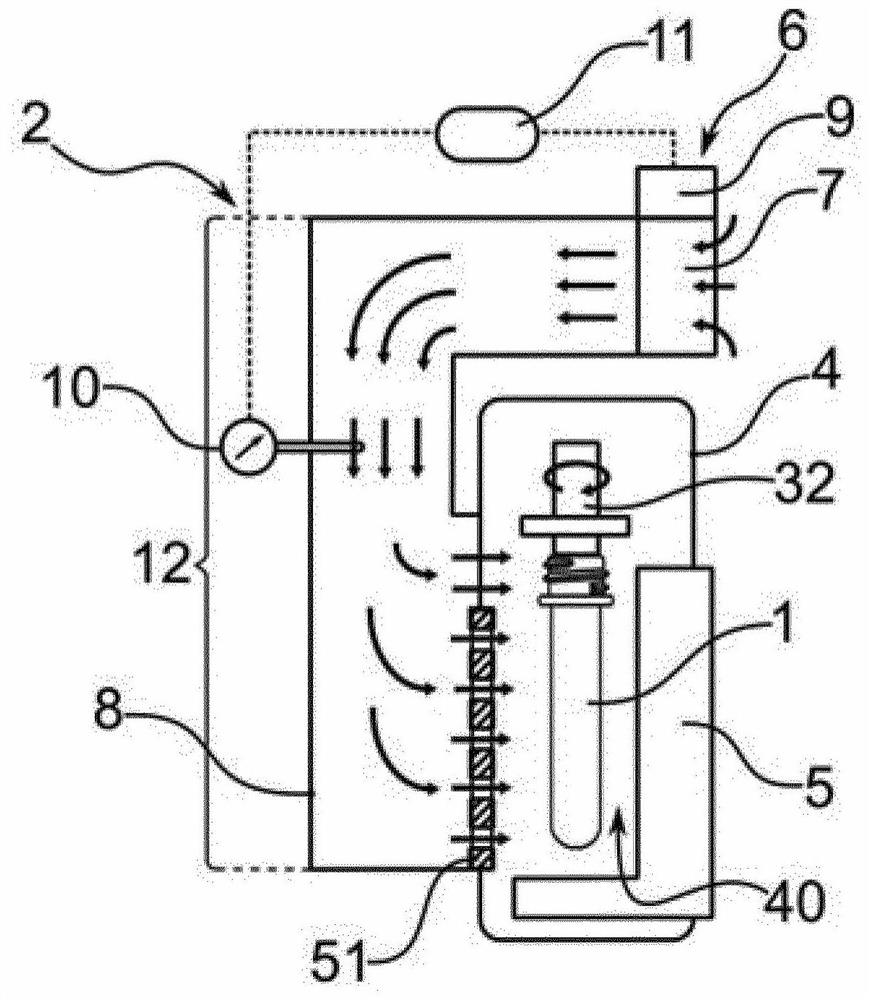

[0049] The present invention relates to thermal conditioning of preforms 1 in the context of the manufacture of plastics material containers obtained by transforming preforms 1 by a stretch blow molding operation.

[0050] Preferably, but not limitatively, the plastic material may be of any type, preferably PET (polyethylene terephthalate).

[0051] The container takes the form of an ampoule or flask and is made of rigid or semi-rigid plastic material. The container is intended to be used in a non-exhaustive manner as a container for fluids, liquids, powders or granules, especially for agri-food, cosmetic type fluids, liquids, powders or granules dedicated to maintenance or personal hygiene.

[0052] Such containers can be subjected to several different sequential processes: from the manufacture of containers by means of preforms 1 by blow or stretch blow moulding operations, in particular through filling, capping, labelling of products in units, up to batches Pack groups of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com