Groove body structure for large disc type filter and assembly method of groove body structure

A technology of disc filter and tank body, which is applied in separation methods, filtration separation, chemical instruments and methods, etc. It can solve the problems of heavy filter plate weight, slurry sinking tank accidents, slurry sedimentation, etc., and achieve uniform distribution , uniform distribution, avoiding the effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained below in conjunction with the accompanying drawings and examples, which cannot limit the protection scope of the present invention, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

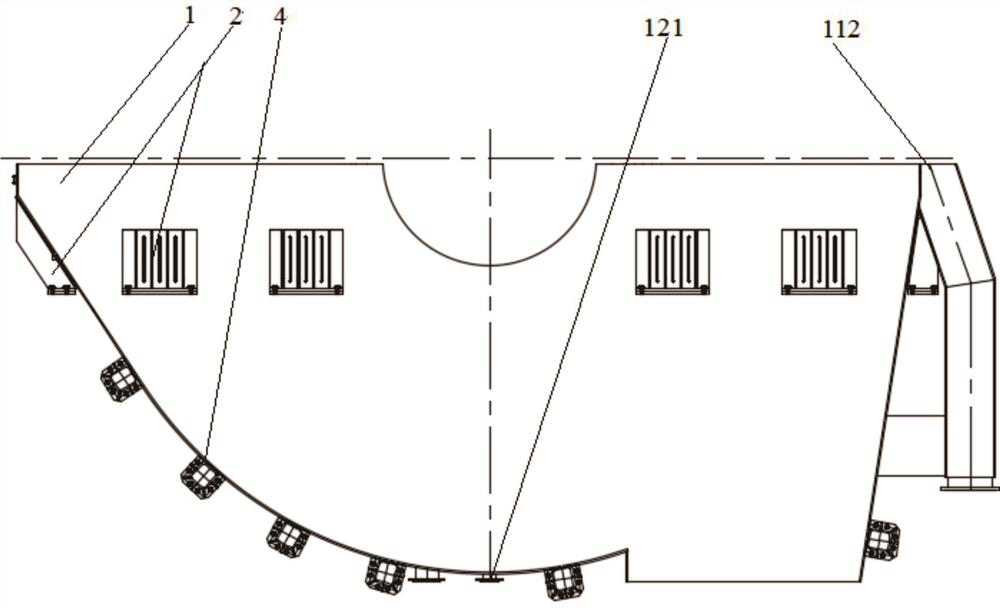

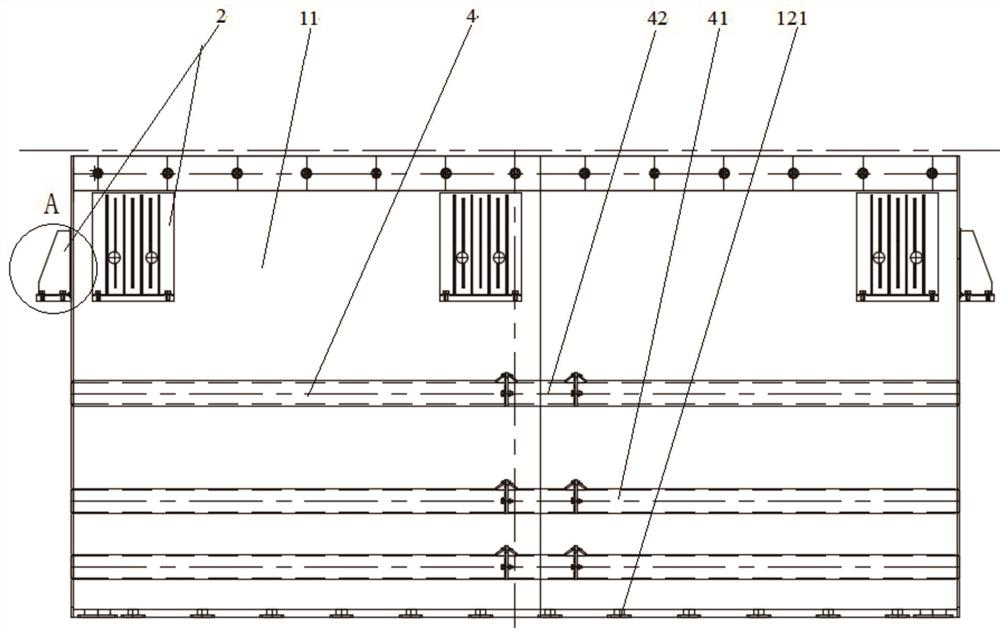

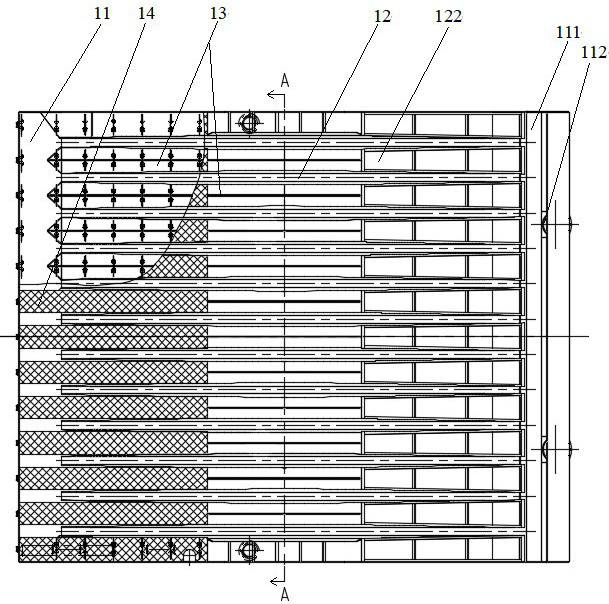

[0032] combined with Figure 1-6 Shown is a tank structure for a large disc filter, including a tank assembly 1, an installation assembly 2, a frame 3 and a support rod assembly 4;

[0033] The tank assembly 1 includes a tank shell 11 and a tank baffle assembly; the upper port of the tank shell 11 is a rectangular structure, and the middle of the upper end of the front side plate and the rear side plate of the tank shell 11 is oppositely provided with a semicircle matching the main shaft of the filter disc. Slot, the left side plate of the tank shell 11 is an arc-shaped plate matched with the filter disc, the right end of the left side plate of the tank shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com