Ultrahigh strength self-compaction bare concrete for wind turbine generator tower

A technology of fair-faced concrete and wind turbines, which is applied in the field of ultra-high-strength self-compacting concrete and ultra-high-strength self-compacting concrete for wind turbine towers. It can solve problems in the initial stage, reduce the maximum peak value of heat of hydration, and improve mechanical properties. And deformation performance, increase the effect of obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of ultra-high-strength self-compacting fair-faced concrete for the tower of a wind power generating set, one square (m 3 ) Concrete components are as follows: cement 400kg, microbeads 126.1kg, grade I fly ash 31.5kg, mineral powder 31.5kg, silica fume 40.9, cellulose fiber 1.2 kg, machine-made sand 820kg, gravel 985kg, water reducer 9.0kg , adding 6.58 kg of compacting agent and 130 kg of water.

[0040] After the materials are ready, the above components are mixed and stirred by a forced mixer for 1.5mim to obtain the ultra-high-strength self-compacting concrete for wind turbine towers described in the present invention.

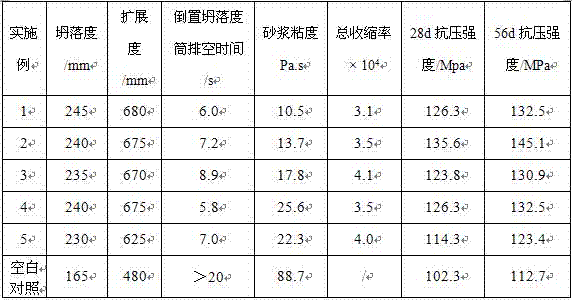

[0041] The concrete of the invention has excellent working performance, low viscosity, and no segregation and bleeding phenomenon. The performance, hardening performance and shrinkage of the concrete mixture are shown in Table 2 below.

Embodiment 2

[0043] A kind of ultra-high-strength self-compacting fair-faced concrete for the tower of a wind power generating set, one square (m 3 ) Concrete components are as follows: cement 408kg, microbeads 149kg, Class I fly ash 37.3Kg, mineral powder 37.3kg, silica fume 48.4, cellulose fiber 1.2 kg, machine-made sand 665kg, gravel 995kg, water reducer 9.5kg, Add 6.2 kg of compacting agent and 130 kg of water.

[0044] After the materials are ready, the above components are mixed and stirred by a forced mixer for 1.5mim to obtain the ultra-high-strength self-compacting concrete for wind turbine towers described in the present invention.

[0045] The concrete of the invention has excellent working performance, low viscosity, and no segregation and bleeding phenomenon. The performance, hardening performance and shrinkage of the concrete mixture are shown in Table 2 below.

Embodiment 3

[0047] A kind of ultra-high-strength self-compacting fair-faced concrete for the tower of a wind power generating set, one square (m 3 ) Concrete components are as follows: cement 400kg, microbeads 126.1kg, grade I fly ash 31.5kg, mineral powder 31.5kg, silica fume 40.9, cellulose fiber 1.2 kg, machine-made sand 670kg, gravel 985kg, water reducer 10.1kg , adding 6.1 kg of compacting agent and 125 kg of water.

[0048] After the materials are ready, the above components are mixed and stirred by a forced mixer for 1.5mim to obtain the ultra-high-strength self-compacting concrete for wind turbine towers described in the present invention.

[0049] The concrete of the invention has excellent working performance, low viscosity, and no segregation and bleeding phenomenon. The performance, hardening performance and shrinkage of the concrete mixture are shown in Table 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com