Cabin paint spraying and repairing device

A paint and cabin technology, which is applied to spray devices, liquid spray devices, and devices for coating liquid on surfaces, etc., can solve the problems of complex nozzle structure, different degrees of repairing spray paint, inconvenient installation and disassembly, etc. Efficiency and quality, accelerated paint repairs, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

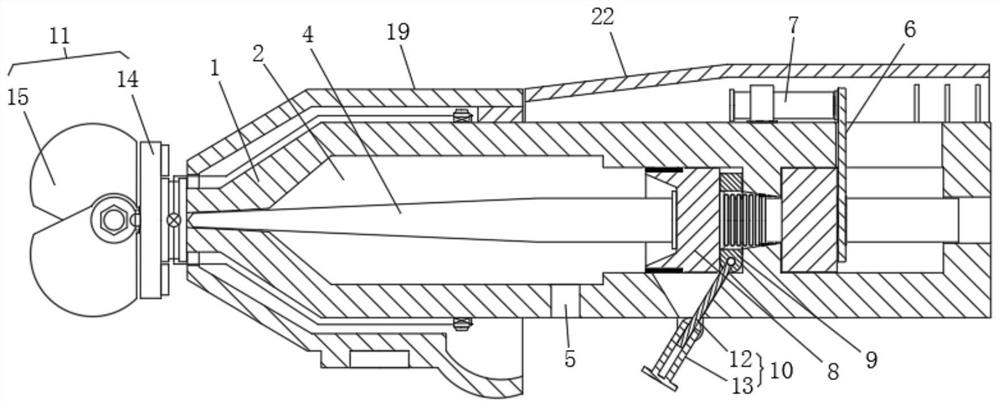

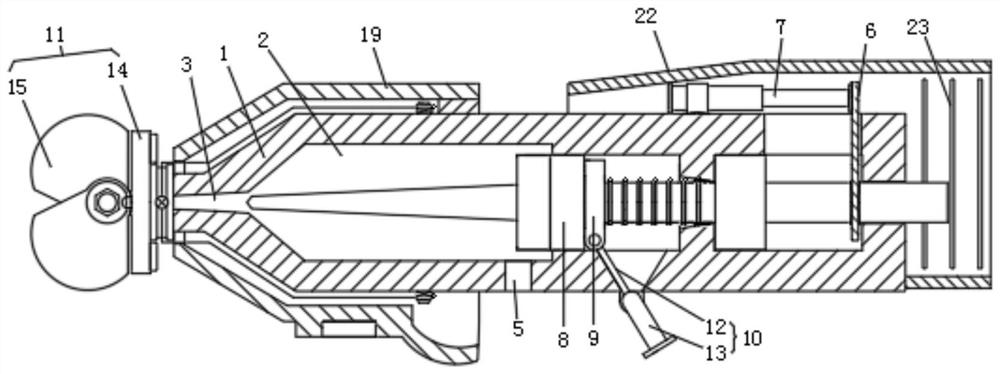

[0031] The technical solutions of the present invention are further described below, but the claimed scope is not limited to the description.

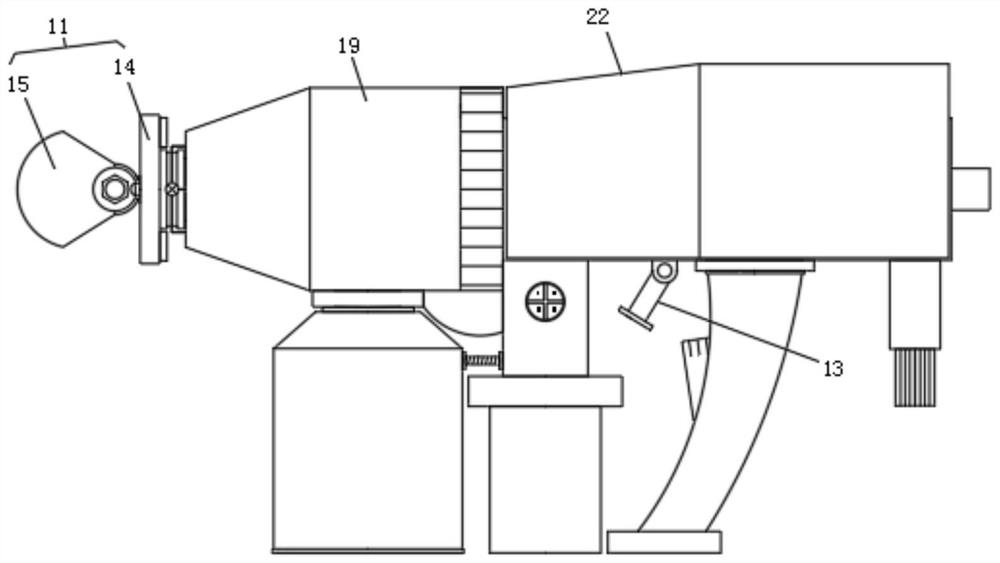

[0032] see Figures 1 to 6 :

[0033] The invention provides a cabin paint spraying and repairing device, comprising:

[0034] Gun body 1, a cavity 2 is provided in the gun body 1, and an access port 5 communicated with the cavity 2 is provided in the middle of the gun body 1;

[0035] The spray head 11 at the front end of the gun body 1, the front part of the cavity 2 communicates with the spray head 11 through the conical compression channel 3;

[0036] The plunger 4 in the gun body 1, the front part of the plunger 4 is a cone corresponding to the compression channel 3, and the rear part of the plunger 4 penetrates the gun body 1 and is provided with a support plate 6;

[0037] The electric telescopic rod 7 fixed on the rear of the gun body 1, the moving end of the electric telescopic rod 7 is connected with the end face of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com