Integrated virus sampling and extracting tube

An extraction tube and one-piece technology, applied in the field of medical equipment, can solve problems such as no space for the user to grasp, difficult for the user to remove or insert the tube cap, and inconvenient use for the user

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

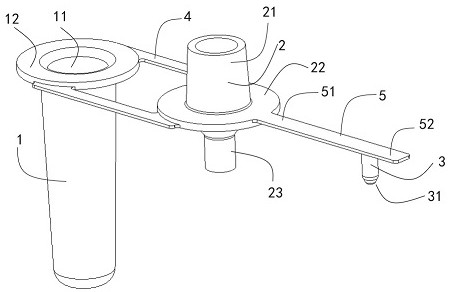

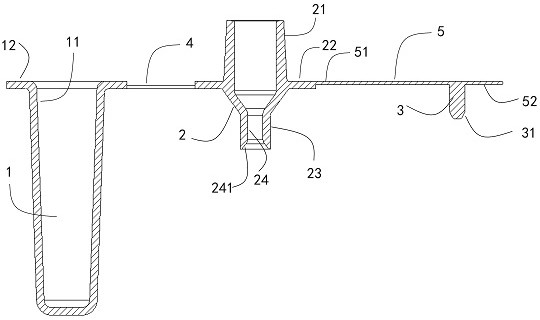

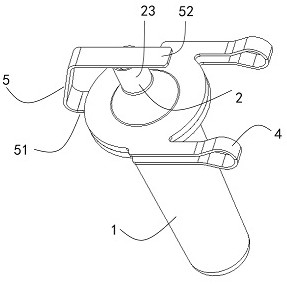

[0019] figure 1 and figure 2 The one-piece virus sampling and extraction tube shown is composed of three parts: the tube body 1, the tube cover 2 and the cover plug 3. The tube cover 2 and the cover plug 3 are located on the same side of the tube body, and the tube cover 2 and the tube body 3 pass through hinged ribs. 4 is connected, the cover plug 3 and the pipe cover 2 are connected by a hinged rib 5, and the hinged rib 5 has an extension 52 after connecting the cover plug 3; the lower part of the pipe cover 2 has a protrusion 23, and the center of the protrusion 23 is a cavity 24. The shape and size of the cap plug 3 correspond to the cavity 24 of the tube cap 2. When the cap plug 3 is inserted into the tube cap 2, the cap plug 3 is just at the position of the cavity 24.

[0020] When the extraction tube manufacturer is in production, the one-piece virus sampling extraction tube is processed and produced by a set of injection molding molds, and no other subsequent assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com