Awning frame with deployment holding mechanism

A technology for holding mechanism and awning, which is applied to tents/canopies, building types, buildings, etc., can solve the problems of inconvenient opening or folding, complex structure of awning frame, and high manufacturing cost, and achieves convenient and labor-saving opening and folding. Improved deployment stability and reliability, and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

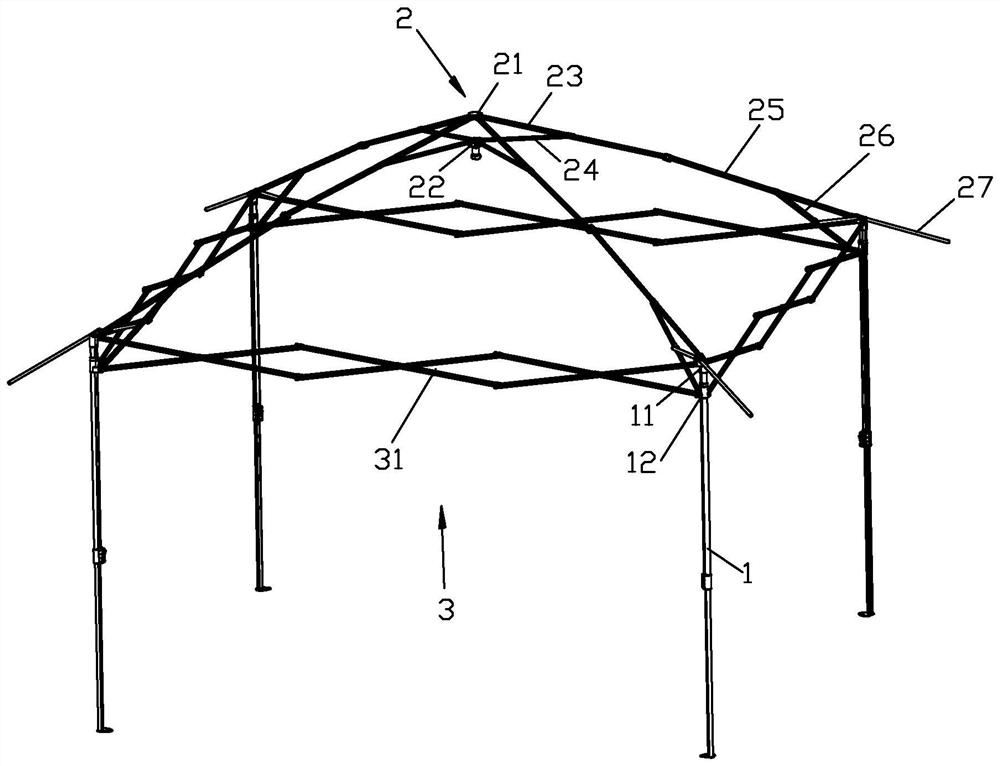

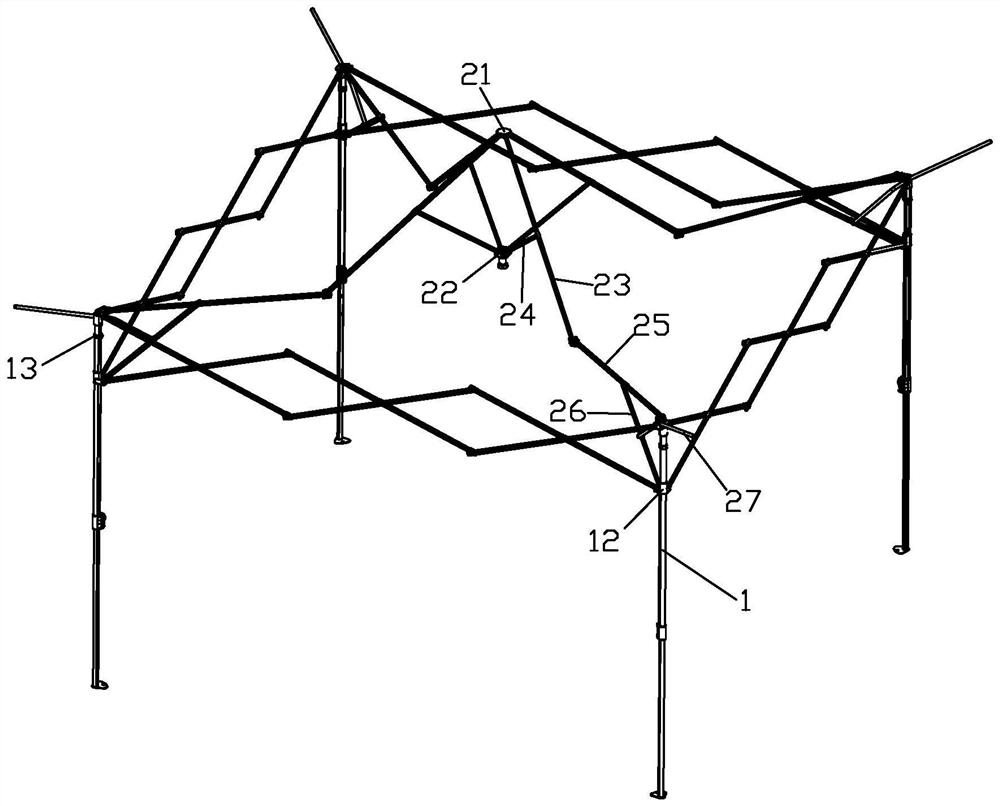

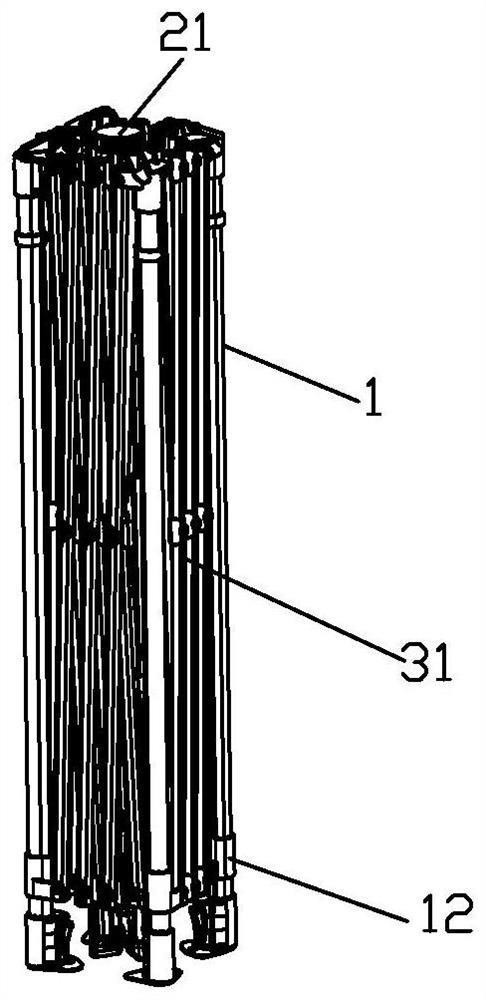

[0047] Please check Figure 1 to Figure 13 , an awning frame with an unfolding and holding mechanism, including N uprights 1, a canopy mechanism 2 and an unfolding and holding mechanism 4, where N is a natural number greater than or equal to 3. A fixing seat 11 is fixed on the top of the column 1, a sliding seat 12 is slidably connected to the column 1, and a limiting mechanism for limiting the sliding seat 12 to the highest position is provided on the column 1. The limiting mechanism can be the one shown in the figure. The limit ring 13 fixed on the column 1 can also be a locking mechanism that directly locks the sliding seat 12 at a predetermined height. The locking mechanism can be a snap lock or a bolt lock, etc.; The arrangement is in a ring-shaped structure, such as a rectangle, a hexagon, etc., and a scissors-type mechanism 3 is connected between the fixed seat 11 and the sliding seat 12 of each adjacent ring-shaped two upright columns 1, and the scissors-type mechanism...

Embodiment 2

[0053] Please check Figure 14 , it differs from the first embodiment in that the unfolding and holding mechanism also includes a second limiting mechanism, the second limiting mechanism replaces the first limiting mechanism, and the second limiting mechanism is connected to the upper connecting seat 21 and the lower connecting The seat 22 also limits the minimum distance between the upper connecting seat 21 and the lower connecting seat 22. It includes a mandrel 211 fixed on the bottom surface of the upper connecting seat 21. The mandrel 211 abuts on the top surface of the lower connecting seat to achieve position limit. The rod is at a deployed angle. According to needs, the first limiting mechanism and the second limiting mechanism may be included at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com