Optical engine assembly equipment and assembly method

A technology for assembling equipment and light engines, which is applied to mechanical equipment, devices for coating liquid on surfaces, connecting components, etc., which can solve the problems of poor matching accuracy and cumbersome assembly operations, and achieve high position matching accuracy and convenient assembly operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

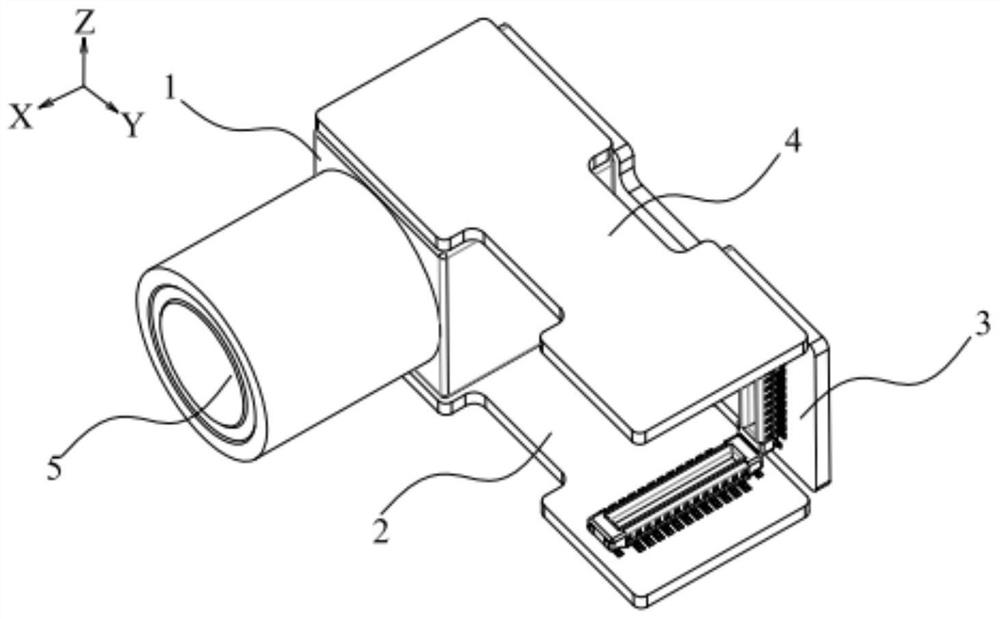

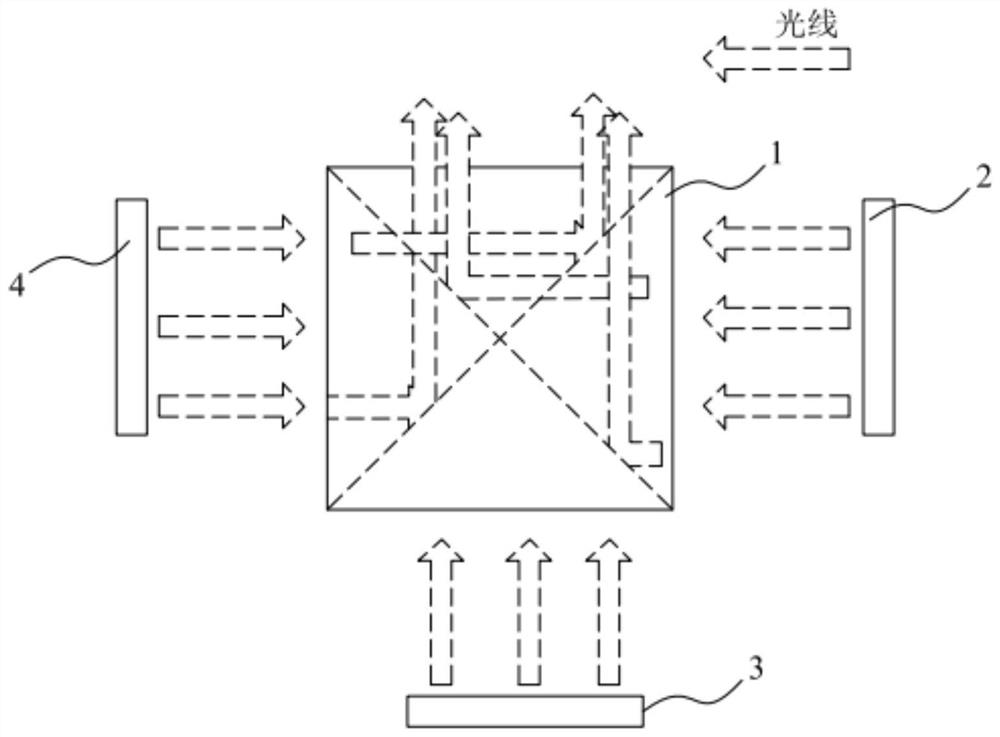

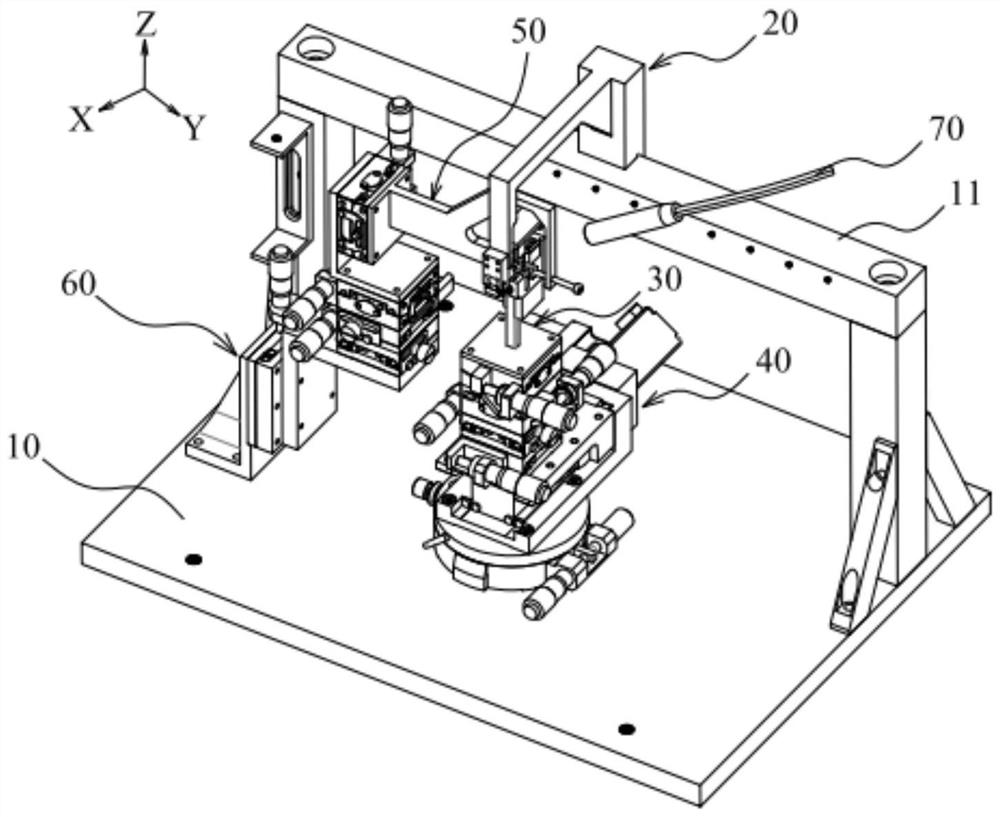

[0066] This embodiment provides a light engine assembling equipment, the light engine structure to be assembled is as follows figure 1 shown. The light engine includes a color combination prism 1 , a first micro display chip 2 , a second micro display chip 3 , a third micro display chip 4 , and an imaging lens 5 respectively mounted on the color combination prism 1 . The color combination prism 1 has a hexahedral structure, the first micro display chip 2 and the third micro display chip 4 are respectively located on opposite sides of the color combination prism 1, and the second micro display chip 3 and the imaging lens 5 are respectively located on the color combination prism 1. In addition, the other two opposite sides of the color combination prism 1 are used as the clamping surfaces for clamping the color combination prism 1 during the assembly process of the light engine. In the specific implementation process, the first micro display chip 2 , the second micro display ch...

Embodiment 2

[0097] The difference between this embodiment and Embodiment 1 is that the assembled light engine has two micro display chips, and the corresponding fitting portion includes a first clamping member and a second clamping member. During specific implementation, the two clamping members enclose an L-shaped structure.

Embodiment 3

[0099] The difference between this embodiment and Embodiment 1 is that the assembled light engine has a micro display chip, and the corresponding attaching part includes a first clamping member. The first clamping member is arranged corresponding to the position where the color combination prism needs to be installed with the micro display chip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com