Super-finishing roller structure

A technology of ultra-finishing roll and roll body, applied in the field of super-finishing roll structure, can solve problems such as stress cracking, achieve the effects of solving stress cracking, reducing the risk of quenching cracking, and facilitating assembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

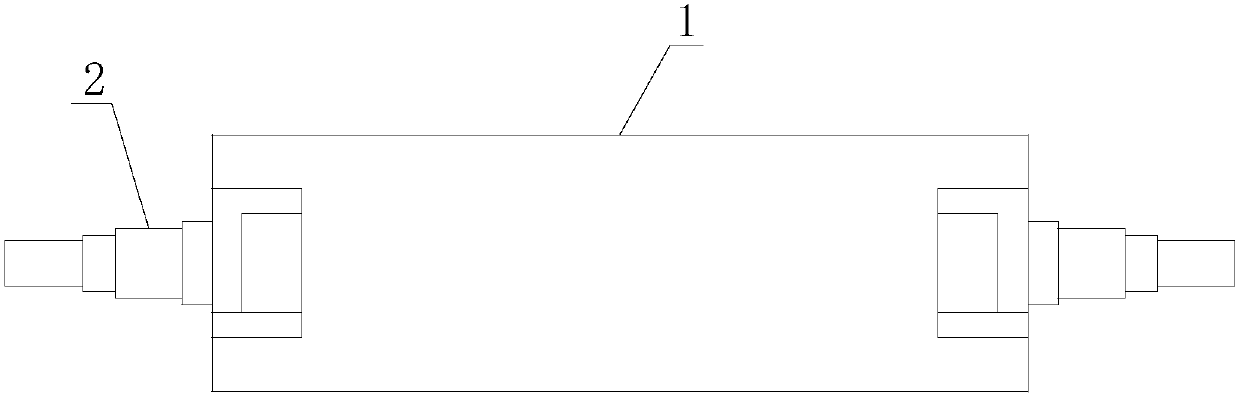

[0010] Such as figure 1 The superfinishing roller structure shown includes a hollow roller body 1 and a journal 2 connected to the inner sides of both ends of the roller body 1. The roller body 1 and the journal 2 have a clearance fit, and the gap is filled with glue. The journal 2 and the roller The gap between bodies 1 is 0.05-0.07mm.

[0011] Heat treatment can be performed on the roller body 1 and the journal 2 separately, which solves the problem that the hardness gradient is difficult to guarantee.

[0012] To a certain extent, the risk of workpiece quenching cracking caused by blank forging defects is effectively reduced. The roll body 1 is changed from the original solid structure to a hollow cylindrical structure with a certain wall thickness, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com