Quenching cooling method for 5CrNiMoV module

A cooling method and quenching furnace technology, applied in the field of alloy steel quenching and cooling, can solve the problems of reduced service life of modules, insufficient cooling speed of oil-cooled quenching, and large difference in hardness between core and surface, so as to reduce the hardness difference and reduce quenching. The effect of cracking risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

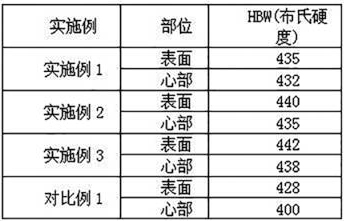

Embodiment 1

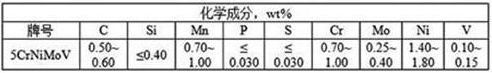

[0012] The 5CrNiMoV modules undergo heat treatment, including quenching and tempering.

[0013] 1. Quenching:

[0014] 1) The module is installed in the furnace, and the temperature is raised to 650°C for 60 minutes with the furnace, and the temperature is continued to 840°C for 3.5 hours;

[0015] 2) Air cooling for 1.5 minutes, the average cooling rate of the module is 70°C / min, water cooling for 2 minutes, the average cooling rate of the module is 150°C / min, oil cooling for 15 minutes, the average cooling zone speed of the module is 24°C / min;

[0016] 2. Tempering: heat preservation at 580°C for 5 hours, then air cool to room temperature.

Embodiment 2

[0018] The 5CrNiMoV modules undergo heat treatment, including quenching and tempering.

[0019] 1. Quenching:

[0020] 1) The module is installed in the furnace, and the temperature is raised to 650°C for 60 minutes with the furnace, and the temperature is continued to 840°C for 3.5 hours;

[0021] 2) Air cooling for 2 minutes, the average cooling rate of the module is 50°C / min, water cooling for 3 minutes, the average cooling rate of the module is 100°C / min, oil cooling for 22.5 minutes, the average cooling zone speed of the module is 16°C / min;

[0022] 2. Tempering: heat preservation at 580°C for 5 hours, then air cool to room temperature.

Embodiment 3

[0024] The 5CrNiMoV modules undergo heat treatment, including quenching and tempering.

[0025] 1. Quenching:

[0026] 1) The module is installed in the furnace, and the temperature is raised to 650°C for 60 minutes, and the temperature is continued to 880°C for 3.5 hours.

[0027] 2) Air cooling for 2 minutes, the average cooling rate of the module is 50°C / min, water cooling for 3 minutes, the average cooling rate of the module is 100°C / min, oil cooling for 22.5 minutes, the average cooling zone speed of the module is 16°C / min; then keep at 580°C for 5 hours air cooled.

[0028] 2. Tempering: heat preservation at 580°C for 5 hours, then air cool to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com