A production method for improving low-temperature toughness of high-strength thick steel plate

A technology of low temperature toughness and production method, used in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of long heating and holding time, unfavorable low temperature toughness, high production cost, and achieve high production efficiency, comprehensive performance improvement, and strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The high-strength steel is composed of the following components (wt%) C: 0.16%, Si: 0.25%, Mn: 1.0%, P≤0.015%, S≤0.008%, Cr: 0.8%, Ni: 0.80%, Mo: 0.35 %, Nb: 0.04%, Ti: 0.015%, B: 0.0015%, and the rest are Fe and inevitable impurities. After smelting according to the above-mentioned composition, it is rolled into a steel plate with a thickness of 30 mm.

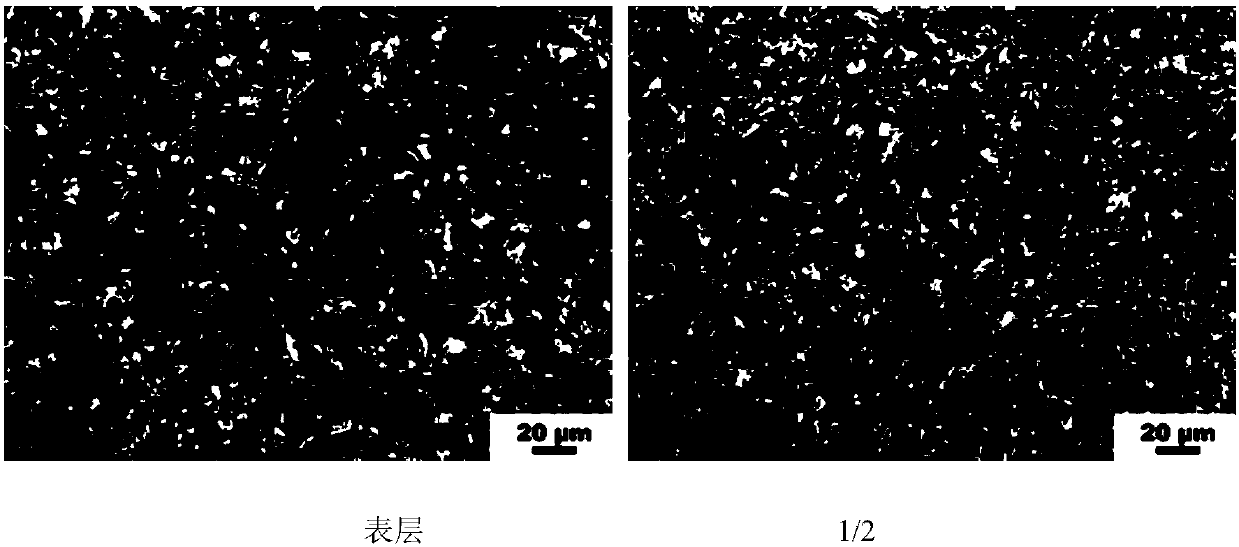

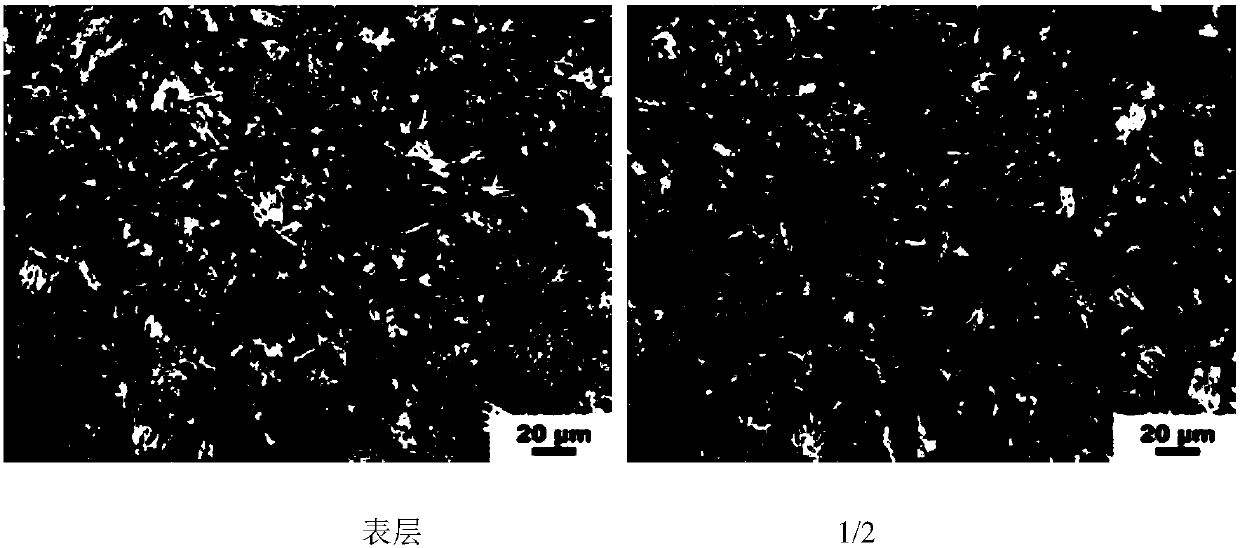

[0023] The rolled steel plate is heated in a nitrogen atmosphere protected heating furnace. The temperature of the steel plate into the furnace is ≤50℃, and the furnace temperature is Ac3+70~120℃. A thermocouple is inserted into the surface layer and the core of the steel plate to measure the surface layer. and heart temperature.

[0024] When the surface temperature is higher than Ac3 or reaches the furnace temperature, and the core temperature is between Ac1 and Ac3, the steel plate is quenched by a roll quenching machine; after quenching, the steel plate is tempered at 250°C.

[0025] The mechanical properties of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com