A thermal sawing process suitable for small round steel bars

A round steel and sawing technology, which is applied in the field of hot sawing of small round steel bars, can solve the problems that the bending in the vertical direction cannot be handled, the sawing speed cannot reach the rolling speed of the rolling mill, and the sawing speed is slow. , to achieve the effect of reducing the time of splashing on the billet, reducing the risk of quenching cracking, and avoiding mutual climbing and entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

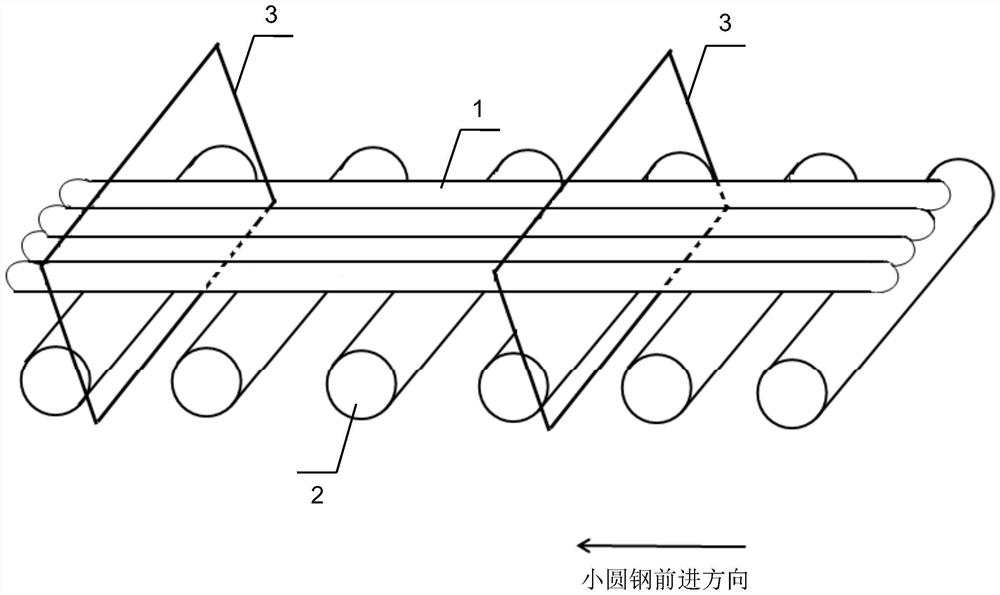

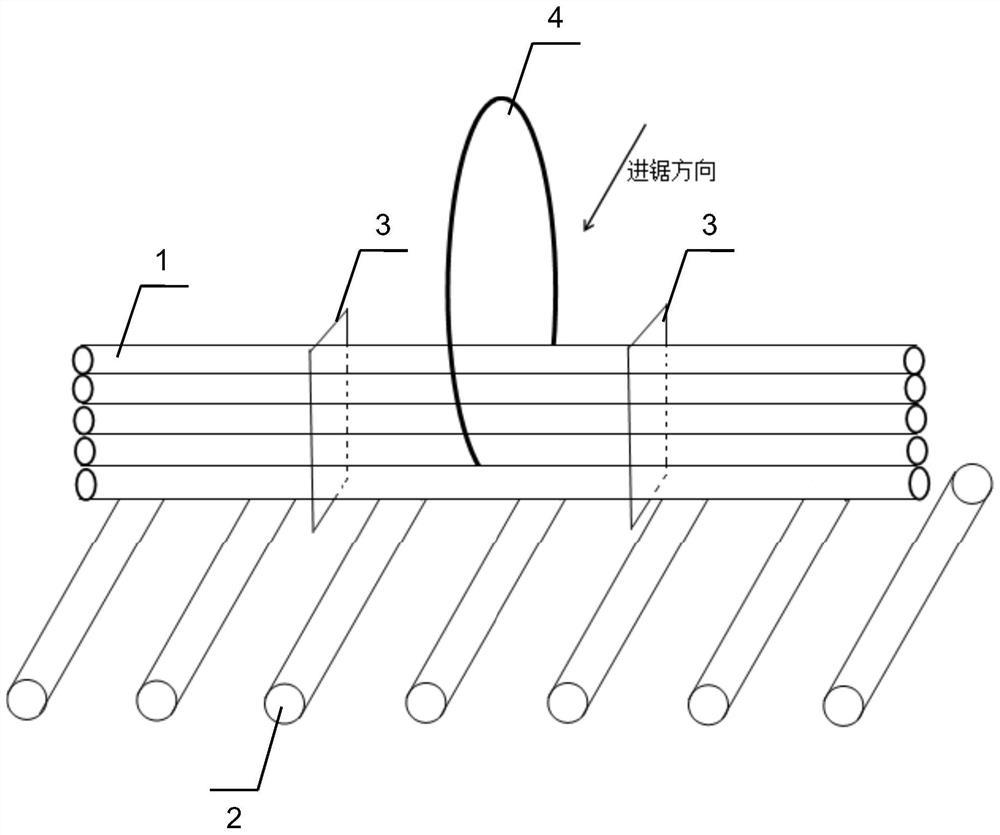

[0032] Please combine Figure 1 to Figure 3 As shown, a kind of hot sawing process suitable for small round steel bars provided by the present invention includes a hot saw machine conveying roller table for conveying small round steel 1, and a hot saw machine conveying roller table is composed of several conveying rollers Road 2 is arranged side by side at equal intervals.

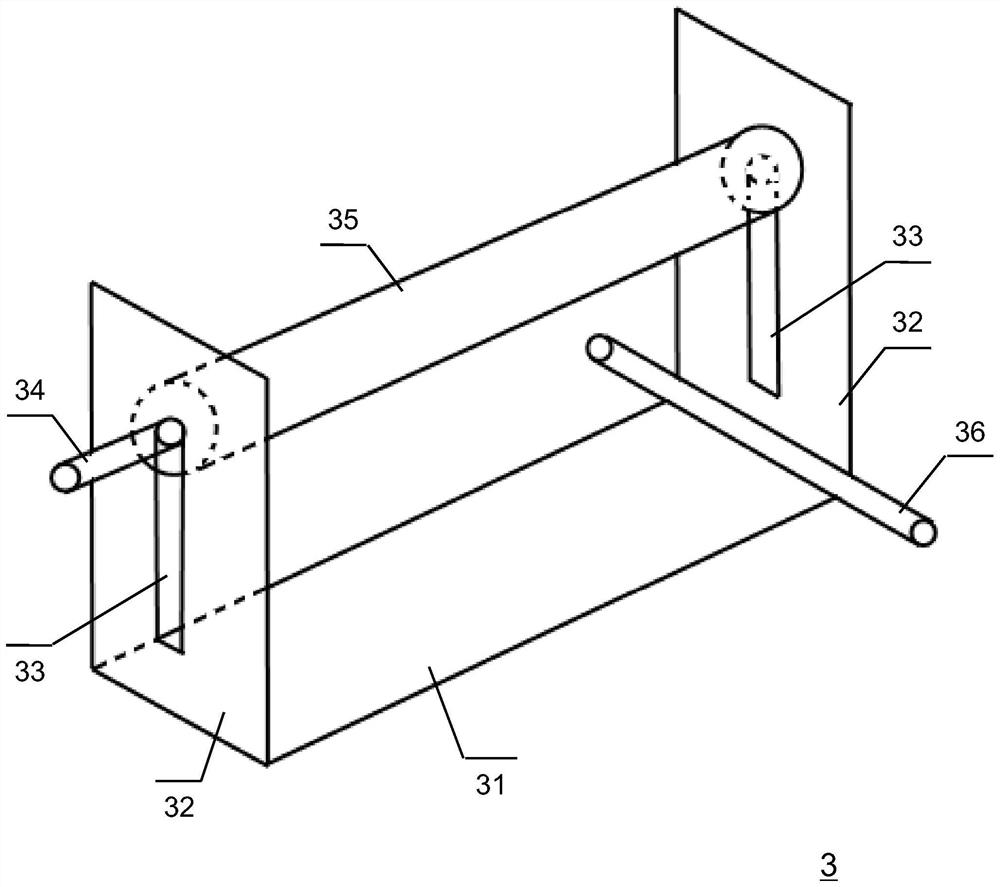

[0033] Place the clamping and straightening device 3 at the space between two adjacent conveying rollers 2 of the conveyor roller table of the hot saw machine. The side baffles 32 at the end, each side baffle 32 is provided with a longitudinal slot 33, and a bearing seat 34 is installed in the longitudinal slot 33, and a compression straightening roller is installed between the two bearing seats 34 35. Under the condition that the width of the conveying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com