Manufacturing method of large module for mold

A manufacturing method and large-scale technology, applied in the field of thermal processing of materials, can solve the problems of unsatisfactory flaw detection, high risk of quenching cracking, and high cost, and achieve the effects of shortening production time and energy consumption, reducing the risk of quenching cracking, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

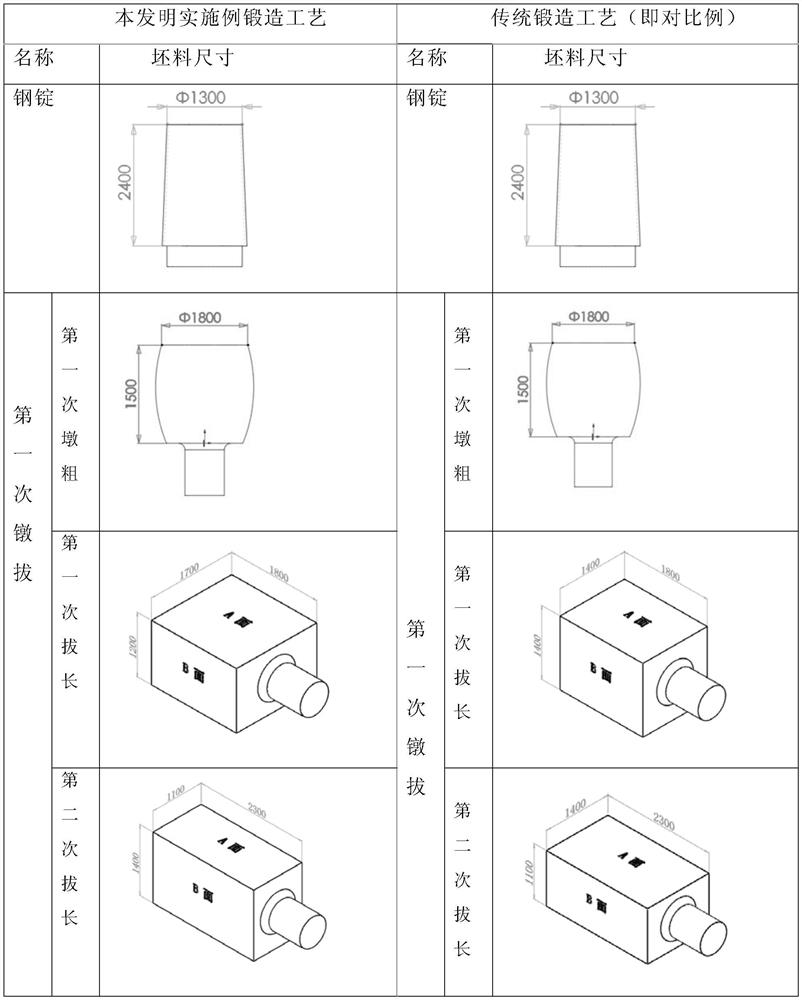

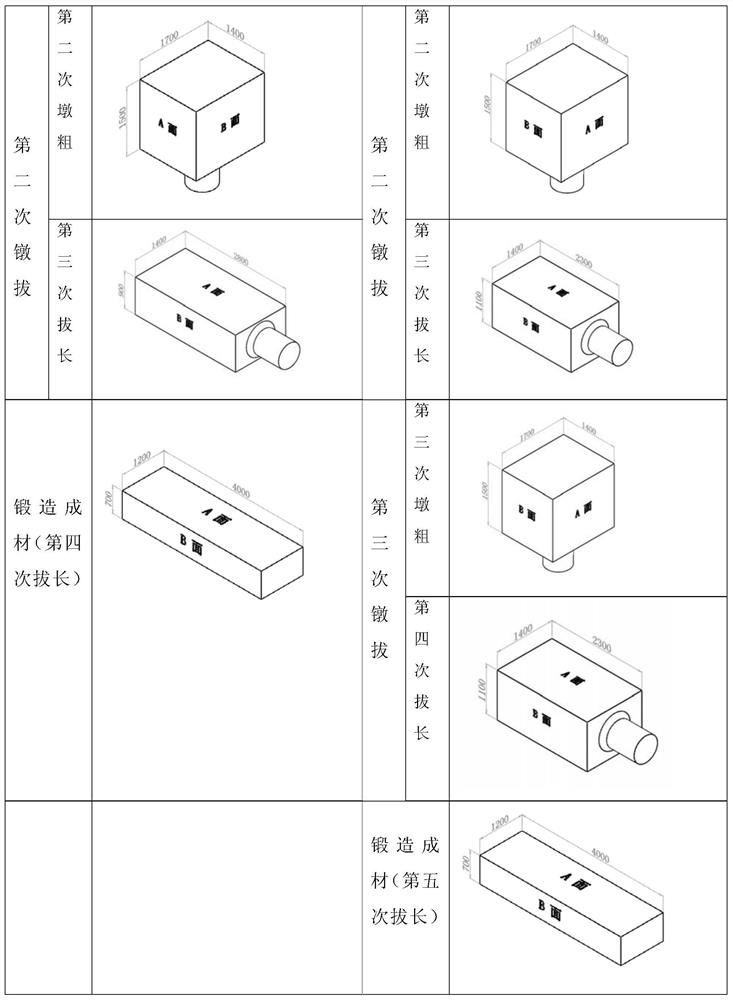

[0035] A preferred embodiment of the manufacturing method of the large-scale mold module provided by the present invention, the process flow is as follows: steel ingot preparation - red delivery of steel ingot for furnace heating - first upsetting - first return to furnace for heat preservation - second upsetting - The second return to the furnace for heat preservation—forging and finishing—flaw detection—finishing—cutting head and tail—inspection—packaging and warehousing.

[0036] The steel ingots used in the following examples and comparative examples are 30 tons of electric furnace octagonal steel ingots. The diameter of the large end of the ingot body is 1380 mm, the diameter of the small end is 1190 mm, and the height of the ingot body is 2400 mm. The chemical composition of steel ingot is referring to table 1, and in the smelting preparation process of steel ingot, the chemical composition content of steel is controlled in the middle upper limit of table 1 content range ...

Embodiment 1

[0041] A method of manufacturing a large module, forging process see figure 1 , including the following steps:

[0042] (1) Heating: First, the steel ingot is sent to be heated, and the steel ingot is sent to the heating furnace after demoulding at about 650°C, and the temperature is raised to 1260-1270°C at a rate of 80°C / h. After reaching the temperature, it is kept for 1 hour. Continue to keep warm at a temperature of 1260-1270°C for 20 hours.

[0043] (2) First upsetting: quickly transfer the steel ingot obtained in step (1) to the fast forging hydraulic press for the first upsetting, the forging temperature is about 1100°C; the specific forging process of the first upsetting is as follows:

[0044] First, the steel ingot is subjected to the first upsetting treatment, that is, the steel ingot is upset to a height of 1500mm (diameter is approximately 1800mm), and the reduction at this time is 37.5%;

[0045] Then, carry out the first elongation process to obtain the first...

Embodiment 2

[0056] A method of manufacturing a large module, comprising the steps of:

[0057](1) Heating: First, the steel ingot is sent to be heated, and the steel ingot is sent to the heating furnace after demoulding at about 650°C, and the temperature is raised to 1260-1270°C at a rate of 80°C / h. After reaching the temperature, it is kept for 1 hour. Continue to keep warm at a temperature of 1260-1270°C for 20 hours.

[0058] (2) First upsetting: quickly transfer the steel ingot obtained in step (1) to the fast forging hydraulic press for the first upsetting, the forging temperature is about 1100°C; the specific forging process of the first upsetting is as follows:

[0059] First, the steel ingot is subjected to the first upsetting treatment, that is, the steel ingot is upset to a height of 1500mm (diameter is approximately 1800mm), and the reduction at this time is 37.5%;

[0060] Then, carry out the first elongation process to obtain the first slab, specifically: firstly chamfer th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com