Static load test method for monitoring bearing capacity of branch pile

A bearing capacity and static load test technology, applied in the direction of applying stable tension/pressure to test material strength, force/torque/power measuring instruments, measuring devices, etc., can solve the lack of standardized data testing process and data analysis methods, The construction lacks accurate and effective guidance, and cannot well reflect the force and bearing performance of pipe piles, so as to achieve the effect of reliable theoretical basis

Pending Publication Date: 2022-08-02

THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In the soft foundation area encountered in traditional bridge engineering, long straight hole cast-in-situ piles are often used to pass through the soft soil layer. Traditional research is carried out by means of field tests and numerical analysis. This technology has poor economic efficiency and design bearing capacity safety reserves for highway bridges and municipal bridge projects. Too big and other issues

At present, although various types of full-scale tests have shown that extruded and expanded abutment piles have bearing advantages in soft soil foundation engineering, there is a lack of in

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

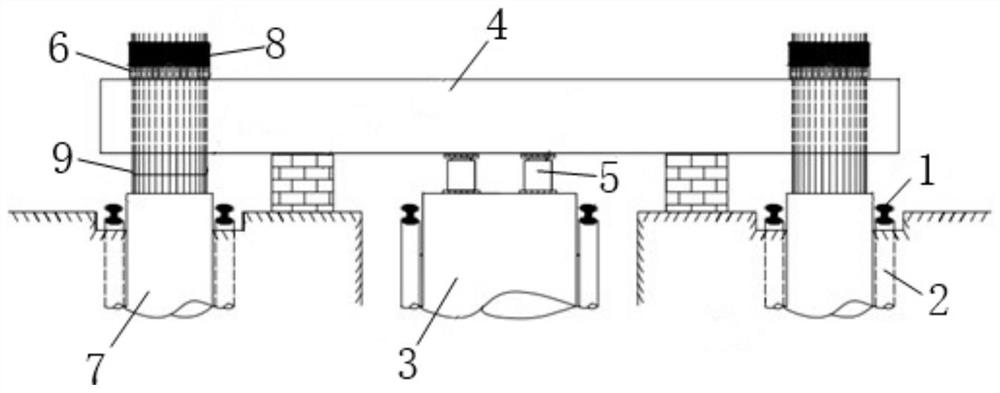

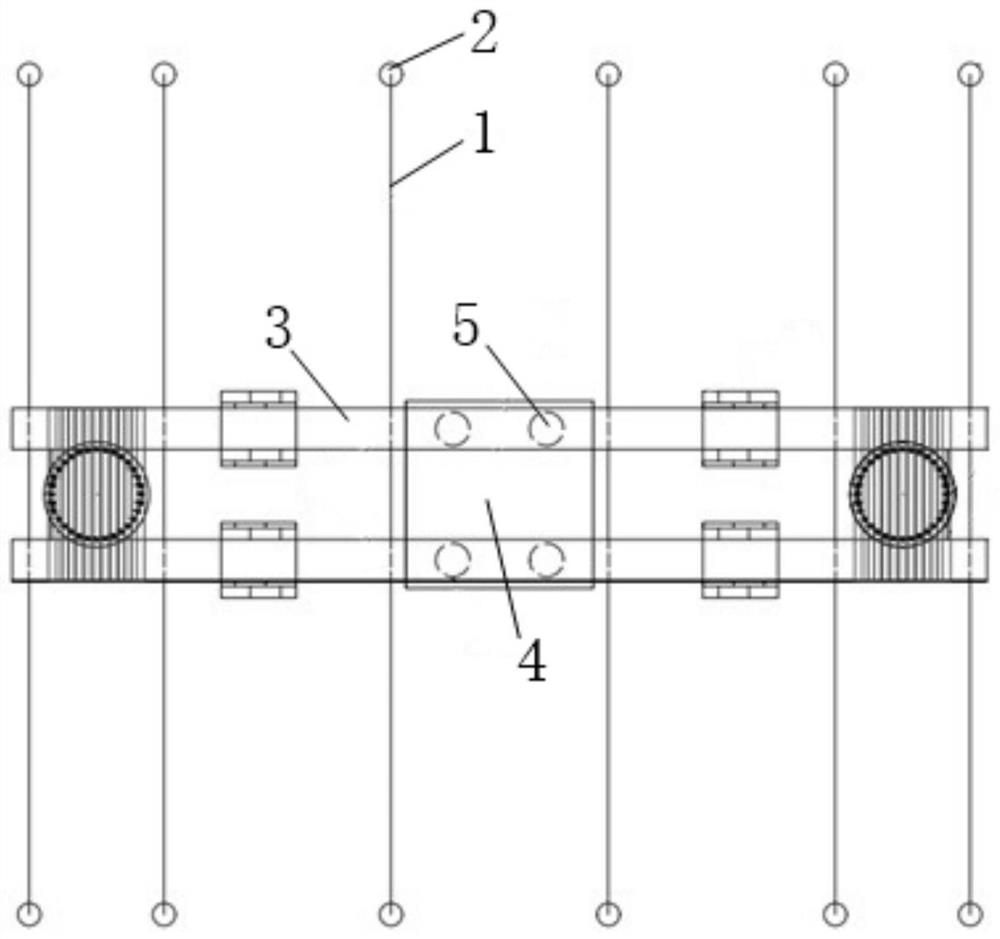

The invention provides a static load test method for monitoring the bearing capacity of a branch pile, which comprises the following steps of: carrying out a single-pile vertical compression resistance static load test on a test pile through a low-speed load maintaining method, and collecting a load applied in the test and displacement and internal force data of the test pile; and the collected data are analyzed and processed to obtain the bearing performance of the test pile. A low-speed load maintaining method is adopted in a static load test of a test pile, automatic loading is achieved through a jack and an oil pump, the displacement of the pile top is monitored through a displacement sensor, and then Q-s and s-lgt curves of the foundation pile are obtained; meanwhile, monitoring the internal force of the pile body by adopting a string-type steel bar meter to calculate and obtain the axial force of the pile body; according to the testing method, the stress and bearing performance of the tubular pile can be well reflected, and reliable data and theoretical basis can be provided for site construction.

Description

technical field [0001] The invention relates to the technical field of building pile foundations, in particular to a static load test method for monitoring the bearing capacity of a support-disk pile. Background technique [0002] The supporting disk pile is a special-shaped pile with a longitudinally variable cross-section. Special squeeze and expansion equipment is used to expand the pile diameter at different sections of the pile to increase the contact area between the pile and the soil to improve the bearing capacity. Compared with traditional cast-in-place piles with straight holes, the extruded and expanded support-disk piles have better bearing performance and can save engineering costs; in addition, the support-disk piles are both environmentally friendly and energy-saving, fast in construction, widely applicable to the piling process, and adjustable in bearing capacity. and many other advantages. Therefore, the squeeze-expanded coil pile has broad application pros...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/12G01N3/06G01C5/00G01L5/00

CPCG01N3/12G01N3/06G01C5/00G01L5/00G01N2203/0003G01N2203/0019G01N2203/0048G01N2203/0676

Inventor 沈道旭韩辉冯金钟浪刘灯明刘欢马伟强

Owner THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com